Abstract

Shrink-fit assemblies have been used to offer a more robust running surface for wooden wheels for a long time. Generally, the two parts are cylindrical or conical. Shrink-fit is now an operation that involves creating contact between two cylinders, there is no third party, and this is good economically. It's employed in a variety of industries, including automotive, aerospace, oil and gas, and train wheels. To do this operation, the inner cylinder's outer radius must be greater than the outer cylinder's inner radius, that difference between them is called 'interference', the latter is being important in the assembly because it contributes to increasing the resistance of the assembly. There are three ways to do this: the first by heating the outer cylinder until it expands, the second by cooling the inner cylinder until it shrinks and the third way is to realize the fitting under a press. When two cylindrical components are assembled by pushing or shrinking one onto the other, at the interface between the two matching parts, a contact pressure and friction force is formed. We study a shrink-fit assembly made up of two hollow cylinders in this paper, taking into account that the contact surfaces are not perfect but contain form defects, we try to know the effect of form defects and their role in the cohesion of the assembly using numerical simulation.

Similar content being viewed by others

Abbreviations

- a :

-

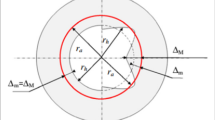

The inner ring's inner radius

- b :

-

The inner ring's nominal outer radius or the outer ring's nominal inner radius

- c :

-

The outer ring's outer radius

- bi :

-

The inner ring's outer radius

- bo :

-

The outer ring's inner radius

- e :

-

Interference

- E :

-

Young's modulus

- \({e}_{ys}\) :

-

Interference to produce the interior face of a hollow shaft

- \({e}_{pcs}\) :

-

Interference that causes the hollow shaft to collapse plastically

- \({e}_{yc}\) :

-

Interference to give the inner face of the cylinder

- r :

-

Radial position

- σr :

-

Radial stress

- σθ :

-

Hoop stress

- \({\sigma }_{VM}\) :

-

Von Mises stress

- \(\varepsilon \) :

-

Strain

- ν :

-

Poisson coefficient

- p :

-

Pressure

- \({A}_{s}\), \({B}_{s}\) :

-

Constant

- \({r}_{c}\) :

-

Elasto-plastic radii in hollow shafts

References

A.A. Burenin, E.P. Dats, A.V. Tkacheva, On the modeling of the shrink fit technology. J. Appl. Ind. Math. 8(4), 493–499 (2014). https://doi.org/10.1134/S199047891404005X

Y. Zhang, B. Mcclain, X.D. Fang, Design of interference fits via finite element method. Int. J. Mech. Sci. 42, 1835–1850 (2000)

N. Laghzale, A. Bouzid, Analytical modelling of elastic-plastic interference fit joints. Int. Rev. Model. Simul. 9(3), 191–199 (2016). https://doi.org/10.15866/iremos.v9i3.8703

A. Mouaa, N.E. Laghzale, A.H. Bouzid, Analytical modelling of interference fit joints with power law strain-hardening behavior. Int. Rev. Model. Simul. 14(1), 24–31 (2021). https://doi.org/10.15866/iremos.v14i1.19126

A. Mouâa, N.E. Laghzale, A.H. Bouzid, Creep analysis of plastically deformed shrink-fitted joints. Arab. J. Sci. Eng. (2021). https://doi.org/10.1007/s13369-021-06192-4

U.A. Campos, D.E. Hall, Simplified Lamé’s equations to determine contact pressure and hoop stress in thin-walled press-fits. Thin-Walled Struct. 138, 199–207 (2019). https://doi.org/10.1016/j.tws.2019.02.008

P. Pedersen, On shrink fit analysis and design. Comput. Mech. 37(2), 121–130 (2006). https://doi.org/10.1007/s00466-005-0664-7

C.-M. Gruescu, A. Davidescu, C. Sticlaru, E.-C. Lovasz, Interference Fits. Bearing Capacity under Complex Loading-FEM analysis, in New Advances in Mechanisms, Mechanical Transmissions and Robotics. MTM&Robotics 2020. Mechanisms and Machine Science. ed. by E.C. Lovasz, I. Maniu, I. Doroftei, M. Ivanescu, C.M. Gruescu (Springer, Cham, 2020)

J.P. Lopes, D.A. Hills, The axisymmetric shrink fit problem subjected to torsion. Int. J. Eng. Sci. 150, 103259 (2020). https://doi.org/10.1016/j.ijengsci.2020.103259

A. Beheshti, M.M. Khonsari, Tribology International Asperity micro-contact models as applied to the deformation of rough line contact. Tribiol. Int. 52, 61–74 (2012). https://doi.org/10.1016/j.triboint.2012.02.026

J.I. McCool, Comparison of models for the contact of rough surfaces. Wear 107(1), 37–60 (1986). https://doi.org/10.1016/0043-1648(86)90045-1

W.R. Chang, I. Bogy, I. Etsion, An elastic-plastic model for the contact of rough surfaces. J. Tribol. 109, 257–263 (1986)

D.M. Bailey, R.S. Sayles, Effect of roughness and sliding friction on contact stresses. J. Tribol. 113(4), 729–738 (1991). https://doi.org/10.1115/1.2920686

J.F. Fontaine, I.E. Siala, Form defect influence on the shrinkage fit characteristics. Eur. J. Mech. A/Solids 17(1), 107–119 (1998). https://doi.org/10.1016/S0997-7538(98)80066-1

S. Belghith, S. Mezlini, H. BelhadjSalah, J.L. Ligier, Modeling of contact between rough surfaces using homogenisation technique. C. R. Mec. 338(1), 48–61 (2010). https://doi.org/10.1016/j.crme.2009.12.003

H. Boutoutaou, M. Bouaziz, J.F. Fontaine, Modeling of interference fits taking form defects of the surfaces in contact into account. Mater. Des. 32(7), 3692–3701 (2011). https://doi.org/10.1016/j.matdes.2011.03.059

Y. Kadin, Y. Kligerman, I. Etsion, Unloading an elastic-plastic contact of rough surfaces. J. Mech. Phys. Solids 54(12), 2652–2674 (2006). https://doi.org/10.1016/j.jmps.2006.04.013

Funding

There is no financial support for this work.

Author information

Authors and Affiliations

Contributions

All authors contributed to the study conception and design. Material preparation, data collection and analysis were performed by [Allal Bedlaoui], [Hamid Boutoutaou]. The first draft of the manuscript was written by [Allal Bedlaoui] and all authors commented on previous versions of the manuscript. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors have no relevant financial or non-financial interests to disclose.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Bedlaoui, A., Boutoutaou, H. Effect of Form Defect in Thin-Walled Cylinder Assembly. J. Inst. Eng. India Ser. C 104, 635–646 (2023). https://doi.org/10.1007/s40032-023-00946-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40032-023-00946-9