Abstract

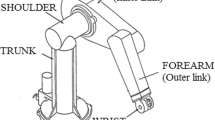

In this paper, an optimal robotic trajectory planning subjected to kinematic and dynamic constraints has been described. The kinematic parameters like jerk and dynamic parameters like torque rate mainly influence the smoothness of the travel of robot end effector along the trajectory path. Therefore, these parameters are to be constrained for reducing the robot positional error, but it leads to vast increase in total travel time of robot which in the end affects the productivity. Therefore, an improved multi-objective ant lion optimization technique has been applied to obtain the optimal trajectory with minimization time-jerk–torque rate for a 6 axis Kawasaki RS06L industrial robot. After implementation of the algorithm, the torque rate and jerk have been reduced considerably and the total travel time before and after optimization has been found to be 34.38 s and 28.21 s.

Similar content being viewed by others

References

A.A. Ata, Optimal trajectory planning of manipulators: a review. J. Eng. Sci. Technol. 2, 32–54 (2007)

A. Rout, B.B.V.L. Deepak, B.B. Biswal, Advances in weld seam tracking techniques for robotic welding: a review. Robot. Comput. Integr. Manuf. 56, 12–37 (2019). https://doi.org/10.1016/j.rcim.2018.08.003

C. Lin, P. Chang, J.Y.S. Luh, Formulation and optimization of cubic polynomial joint trajectories for industrial robots. IEEE Trans. Autom. Control 28, 1066–1074 (1983)

A. Gasparetto, V. Zanotto, A new method for smooth trajectory planning of robot manipulators. Mech. Mach. Theory 42, 455–471 (2007). https://doi.org/10.1016/j.mechmachtheory.2006.04.002

A. Gasparetto, V. Zanotto, Optimal trajectory planning for industrial robots. Adv. Eng. Softw. 41, 548–556 (2010). https://doi.org/10.1016/j.advengsoft.2009.11.001

A. Gasparetto, A. Lanzutti, R. Vidoni, V. Zanotto, Experimental validation and comparative analysis of optimal time-jerk algorithms for trajectory planning. Robot. Comput. Integr. Manuf. 28, 164–181 (2012). https://doi.org/10.1016/j.rcim.2011.08.003

A. Piazzi, A. Visioli, An interval algorithm for minimum-jerk trajectory planning of robot manipulators, in Proceedings of the 36th IEEE Conference Decision Control, vol. 2 (1997), pp. 1924–1927. https://doi.org/10.1109/CDC.1997.657874

A. Piazzi, A. Visioli, Global minimum-jerk trajectory planning of robot manipulators. IEEE Trans. Ind. Electron. 47, 140–149 (2000)

P. Huang, Y. Xu, B. Liang, Global minimum-jerk trajectory planning of space manipulator. Int. J. Control. Autom. Syst. 4, 405–413 (2006)

V. Zanotto, A. Gasparetto, A. Lanzutti et al., Experimental validation of minimum time-jerk algorithms for industrial robots. J. Intell. Robot. Syst. Theory. Appl. 64, 197–219 (2011). https://doi.org/10.1007/s10846-010-9533-5

P. Huang, K. Chen, J. Yuan, Y. Xu, Motion trajectory planning of space manipulator for joint, in International Conference Mechatronics Automation 2007, ICMA (2007), pp. 3543–3548. https://doi.org/10.1109/ICMA.2007.4304134

A. Rout, M. Dileep, G. Bihari et al., ScienceDirect Optimal time-jerk trajectory planning of 6 axis welding robot using TLBO method. Proc. Comput. Sci. 133, 537–544 (2018). https://doi.org/10.1016/j.procs.2018.07.067

P. Huang, G. Liu, J. Yuan, Y. Xu (2008) Multi-objective optimal trajectory planning of space robot using particle swarm optimization. In: International Symposium on Neural Networks. Springer, Berlin, pp. 171–179

H. Lin, A fast and unified method to find a minimum-jerk robot joint trajectory using particle swarm optimization. J. Intell. Robot. Syst. Theory Appl. 75, 379–392 (2014). https://doi.org/10.1007/s10846-013-9982-8

K.G. Shin, N.D. McKay, Minimum-time trajectory planning for industrial robots with general torque constraints, in IEEE International Conference on Robotics and Automation Proceedings (1986) , pp. 412–417

C. Guarino, L. Bianco, A. Piazzi, Minimum-time trajectory planning of mechanical manipulators under dynamic constraints (2010), p. 7179. https://doi.org/10.1080/00207170210156161

H.A. AI-Dois, A.K. Jha, R.B. Misra, Dynamic manipulability of 3-RRR planar manipulator. J. Inst. Eng. (India) Ser. C 93, 257–267 (2012). https://doi.org/10.1007/s40032-012-0024-2

M. Chandrasekaran, S. Tamang, ANN–PSO integrated optimization methodology for intelligent control of MMC machining. J. Inst. Eng. Ser. C 98, 395–401 (2017). https://doi.org/10.1007/s40032-016-0276-3

V. Muthukumar, A.S. Babu, R. Venkatasamy, N.S. Kumar, An accelerated particle swarm optimization algorithm on parametric optimization of WEDM of die-steel. J. Inst. Eng. (India) Ser. C 96, 49–56 (2015). https://doi.org/10.1007/s40032-014-0143-z

S. Rajakumar, D. Ravindran, M. Sivakumar, Optimization of power coefficient of wind turbine using genetic algorithm. J. Inst. Eng. Ser. C 98, 111–118 (2017). https://doi.org/10.1007/s40032-016-0323-0

R. Seshasai, S. Prasanth, K. Hans, Optimization of straight cylindrical turning using artificial bee colony (ABC) algorithm. J. Inst. Eng. Ser. C 98, 171–177 (2017). https://doi.org/10.1007/s40032-016-0263-8

D.G.S. Chakraborty, A study on the optimization performance of fireworks and Cuckoo search algorithms in laser machining processes. J. Inst. Eng. Ser. C 96, 215–229 (2015). https://doi.org/10.1007/s40032-014-0160-y

S. Mirjalili, P. Jangir, S. Saremi, Multi-objective ant lion optimizer: a multi-objective optimization algorithm for solving engineering problems. Appl. Intell. (2017). https://doi.org/10.1007/s10489-016-0825-8

S. Mirjalili, The ant lion optimizer. Adv. Eng. Softw. 83, 80–98 (2015). https://doi.org/10.1016/j.advengsoft.2015.01.010

K. Deb, A robust evolutionary framework for multi-objective optimization, in Proceedings of the 10th Annual Conference on Genetic and Evolutionary Computation. Atlanta, Georgia, USA, (2008), pp. 633–640

Acknowledgments

This research work is supported by Board of Research in Nuclear Sciences, Department of Atomic Energy, Govt. of India under Project ID BRNS/34034.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Rout, A., Mahanta, G.B., Bbvl, D. et al. Kinematic and Dynamic Optimal Trajectory Planning of Industrial Robot Using Improved Multi-objective Ant Lion Optimizer. J. Inst. Eng. India Ser. C 101, 559–569 (2020). https://doi.org/10.1007/s40032-020-00557-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40032-020-00557-8