Abstract

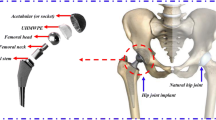

Abrasive flow finishing (AFF) is a non-conventional finishing technique that offers better accuracy, efficiency, consistency, economy in finishing of complex/difficult to machine materials/components and provides the possibility of effective automation as aspired by the manufacturing sector. The present study describes the finishing of a hip joint made of ASTM grade Co–Cr alloy by Abrasive Flow Machining (AFM) process. The major input parameters of the AFF process were optimized for achieving nanometric finishing of the component. The roughness average (Ra) values were recorded during experimentation using surface roughness tester and the results are discussed in detail. The surface finished hip joints were characterized using Scanning Electron Microscopy (SEM), Atomic Force Microscopy (AFM) and residual stress analysis using X-Ray Diffraction (XRD). The discussion lays emphasis on the significance, efficacy and versatile nature of the AFF process in finishing of bio-medical implants.

Similar content being viewed by others

References

L.J. Rhoades, Abrasive flow machining: a case study. J. Mater. Process. Technol. 28, 107–116 (1991)

L.J. Rhoades, Abrasive flow machining. Manuf. Eng. 101, 75–78 (1988)

P.A. McKeown, The role of precision engineering in manufacturing of the future. Ann. CIRP 36(2), 495–501 (1987)

P.J. Davies, A.J. Fletcher, The assessment of the rheological characteristics of various polyborosiloxane/grit mixtures as utilized in the abrasive flow machining. Proc. Inst. Mech. Eng. 209, 409–418 (1995)

A.J. Fletcher, J.B. Hull, J. Mackie, S.A. Trengove, Computer modeling of the abrasive flow machining process, in Proceedings of International Conference on Surface Engineering, (1990), Toronto, pp. 592–601

L.J. Rhoades, T.A. Kohut, Reversible Unidirectional AFM, U.S. Patent 5,070,652, 10 Dec (1991)

L.J. Rhoades, T.A. Kohut, N.P. Nokovich, D.W. Yanda, Unidirectional abrasive flow Machining, U.S. Patent 5, 367, 833, 29 Nov (1994)

H. Hermawan, D. Ramdan, J.R.P. Djuansjah, Metals for biomedical applications. www.intechopen.com

D. Peckner, I.M. Bernstein, Handbook of Stainless Steels (McGraw-Hill Inc., New York, 1977)

S.Y. Zeng, L. Blunt, X. Jiang, The application of Taguchi approach to optimise the processing conditions on bonnet polishing of Co–Cr. Key Eng. Mater. 496, ISSN 1013-9826, pp. 235–240 (2011)

D.H. Kohn, Metals in medical applications. Curr. Opin. Solid State Mater. Sci. 3, 309 (1998)

C. Aparicioa, F.J. Gil, C. Fonseca, M. Barbosa, J.A. Planell, Corrosion behavior of commercially pure Ti shot blasted with different materials and sizes of shot particles for dental implant applications. Biomaterials 24, 263 (2003)

S.L. Smith, D. Dowson, A.A.J. Goldsmith, The effect of femoral head diameter upon lubrication and wear of metal-on-metal total hip replacement. Proc. Inst. Mech. Eng. Part H 215, 161–170 (2001)

Z.M. Jin, Analysis of mixed lubrication mechanism in metal-on-metal hip joint replacements. Proc. Inst. Mech. Eng. Part H 216, 85–89 (2002)

J. O’Kelly, A. Unsworth, D. Dowson, V. Wright, A comparative joint simulator study of the wear of metal-on-metal and alternative material combinations in hip replacements. Eng. Med. 8, 153–159 (1979)

Y. Liao, E. Hoffman, M. Wimmer, A. Fischer, J. Jacobs, Laurence Marks, Co–CrMo metal-on-metal hip replacements. Phys. Chem. Chem. Phys. 15(3), 746–756 (2013)

H.R.S. Hosseinzadeh, A. Eajazi, A.S. Shahi, The bearing surfaces in total hip arthroplasty—options, material characteristics and selection, recent advances in arthroplasty, Samo Fokter (Ed.), ISBN: 978-953-307-990-5 (2012)

S.M. Ravi, V.K. Jain, J. Ramkumar, Experimental investigations into rotating work piece abrasive flow finishing. Wear 267(1–4), 43–45 (2009)

S.M. Ravi, V.K. Jain, J. Ramkumar, Effect of Abrasive Medium ingredients on finishing of Al alloy and Al alloy/SiC metal matrix composites using rotational abrasive flow finishing. Appl. Mech. Mater. 110–116, 1328–1335 (2012)

V.K. Gorana, V.K. Jain, G.K. Lal, Prediction of surface roughness during abrasive flow machining. J. Adv. Manuf. Technol. 31, 258–267 (2006)

K. Przyklenk, Abrasive flow machining: a process for surface finishing and deburring of work piece with a complicated shape by means of an abrasive laden medium. Adv. Non-tradit Mach. PED 22, 101–110 (1986)

V.K. Gorana, V.K. Jain, G.K. Lal, Cutting forces and surface roughness during abrasive flow machining. in Proceedings of Precision Engineering ed. by M.V Suryaprakash et al. (Narosa Publishing House, New Delhi, 2004), pp. 298–305

V.K. Gorana, V.K. Jain, G.K. Lal, Experimental investigation into cutting forces and active grain density during abrasive flow machining. Int. J. Mach. Tools Manuf. 44, 201–211 (2004)

S. Jha, V.K. Jain, S.K. Choudhury, On the performance of Abrasive flow finishing process. in Proceedings of Precision Engineering, ed. by M.V. Suryaprakash et al (Narosa Publishing House, New Delhi, 2004), pp. 216–223

M. Alitavoli, M. Mehran, An experimental approach to Abrasive Flow Machining process. Tehran International Congress on Manufacturing Engineering (TICME 2005)

R.K. Jain, V.K. Jain, Simulation of surface generated in abrasive flow machining process. Robot. Comput. Integr. Manuf. 15, 403–412 (1999)

R.K. Jain, V.K. Jain, Effects of operating parameters on performance of abrasive flow machining process. Proceedings of 20th AIMTDR conference held at Birla Institute of Technology, Mesra Ranchi, pp. 224229 (2004)

R.E. Williams, K.P. Rajurkar, Stochastic modeling and analysis of abrasive flow machining. Trans. ASME J. Eng. Ind. 114, 74–81 (1992)

R.K. Jain, V.K. Jain, Abrasive fine finishing processes—a review. Int. J. Manuf. Sci. Prod. 2(1), 55–68 (1999)

Acknowledgments

The authors are thankful to the Director, Central Manufacturing Technology Institute (CMTI), Bangalore for the continued support, encouragement and infrastructural facilities provided. The authors are also thankful to Indian Institute of Technology Kanpur and CMTI, Bangalore for setting up the prototype of AFM at CMTI, Bangalore. The authors would also like to thank Adler Mediequip Pvt. Ltd, Pune for providing the implants.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Subramanian, K.T., Balashanmugam, N. & Shashi Kumar, P.V. Nanometric Finishing on Biomedical Implants by Abrasive Flow Finishing. J. Inst. Eng. India Ser. C 97, 55–61 (2016). https://doi.org/10.1007/s40032-015-0190-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40032-015-0190-0