Abstract

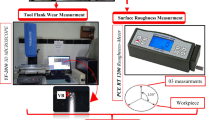

In the present study, an attempt has been made to apply the Taguchi parameter design method and regression analysis for optimizing the cutting conditions on surface finish while machining AISI 4340 steel with the help of the newly developed yttria based Zirconia Toughened Alumina (ZTA) inserts. These inserts are prepared through wet chemical co-precipitation route followed by powder metallurgy process. Experiments have been carried out based on an orthogonal array L9 with three parameters (cutting speed, depth of cut and feed rate) at three levels (low, medium and high). Based on the mean response and signal to noise ratio (SNR), the best optimal cutting condition has been arrived at A3B1C1 i.e. cutting speed is 420 m/min, depth of cut is 0.5 mm and feed rate is 0.12 m/min considering the condition smaller is the better approach. Analysis of Variance (ANOVA) is applied to find out the significance and percentage contribution of each parameter. The mathematical model of surface roughness has been developed using regression analysis as a function of the above mentioned independent variables. The predicted values from the developed model and experimental values are found to be very close to each other justifying the significance of the model. A confirmation run has been carried out with 95 % confidence level to verify the optimized result and the values obtained are within the prescribed limit.

Similar content being viewed by others

References

A. Hasçalik, U. Çaydaş, Optimization of turning parameters for surface roughness and tool life based on the Taguchi method. Int. J. Adv. Manuf. Technol. 38, 896–903 (2008)

S. Shaji, V. Radhakrishnan, Analysis of process parameters in surface grinding with graphite as lubricant based of the Taguchi method. J. Mater. Process. Technol. 141(1), 51–59 (2003)

W.H. Yang, Y.S. Tarng, Design optimization of cutting parameters for turning operations based on the Taguchi method. J. Mater. Process. Technol. 84, 122–129 (1998)

G. Taguchi, Introduction to Quality Engineering (Asian Productivity Organization (APO), Tokyo, 1990)

D.E. Kirby, Z. Zhang, C.J. Chen, J. Chen, Optimizing surface finish in a turning operation using the Taguchi parameter design method. Int. J. Adv. Manuf. Technol. 30, 1021–1029 (2006)

S.T. Lan, Y.M. Wang, Competitive parameter optimization of multi quality CNC turning. Int. J. Adv. Manuf. Technol. 41, 820–826 (2009)

C.Y. Nian, W.H. Yang, Y.S. Tarng, Optimization of turning operations with multiple performance characteristics. J. Mater. Process. Technol. 95, 90–96 (1996)

J. Kopač, M. Bahor, M. Soković, Optimal machining parameters for the desired surface roughness in fine turning of cold pre-formed steel work pieces. Int. J. Mach. Tools Manuf 42, 707–716 (2002)

A. Vernon, T. Ozel, Factors affecting surface roughness in finish hard turning, Report MARL-03-01 (Rutgers University, Piscataway, 2003)

M. Nalbant, H. Gokkaya, G. Sur, Application of Taguchi method in optimization of cutting parameters for surface roughness in turning. Mater. Des. 28, 1379–1385 (2007)

E. Aslan, N. Camuscu, B. BirgÖren, Design optimization of cutting parameters when turning hardened AISI 4140 steel (63 HRC) with Al2O3+TiCN mixed ceramic tool. Mater. Des. 28, 1618–1622 (2007)

I. Asiltürk, H. Akkus, Determining the effect of cutting parameters on surface roughness in hard turning using the Taguchi method. Measurement 44(9), 1697–1704 (2011)

J.P. Davim, Note on the determination of optimal cutting conditions for surface finish obtained in turning using design of experiments. J. Mater. Process. Technol. 116, 305–308 (2001)

B. Mondal, A.B. Chattopadhya, A. Virkar, A. Paul, Development and performance of zirconia-toughened alumina ceramic tools. Wear 156, 365–383 (1992)

B. Mondal, Zirconia toughened alumina for wear resistant engineering and machinability of steel application. Adv. Appl. Ceram. 104(5), 256–260 (2005)

A. Senthil Kumar, A. Raja Durai, T. Sornakumar, Development of aluminium—ceria ceramic composite cutting tool. Int. J. Refract. Met. Hard Mater. 22, 17–20 (2004)

A. Senthil Kumar, A. Raja Durai, T. Sornakumar, Machinability of hardened steel using aluminium based ceramic cutting tools. Int. J. Refract. Met. Hard Mater. 21, 109–117 (2003)

N. Mandal, B. Doloi, B. Mondal, Development of flank wear prediction model of Zirconia Toughened Alumina (ZTA) cutting tool using response surface methodology. Int. J. Refract. Met. Hard Mater. 29(2), 273–280 (2011)

N. Mandal, B. Doloi, B. Mondal, R. Das, Optimization of flank wear using Zirconia Toughened Alumina (ZTA) cutting tool: Taguchi method and regression analysis. Measurement 10(44), 2149–2155 (2011)

N. Mandal, B. Doloi, B. Mondal, Force prediction model of Zirconia Toughened Alumina (ZTA) inserts in hard turning of AISI 4340 steel using response surface methodology. Int. J. Precis. Eng. Man 13(9), 1589–1599 (2012)

N. Mandal, B. Doloi, B. Mondal, Predictive modeling of surface roughness in high speed machining of AISI 4340 steel using yttria stabilized zirconia toughened alumina turning insert. Int. J. Refract. Met. Hard Mater. 38, 40–46 (2013)

Acknowledgments

The authors are thankful to CSIR-Central Mechanical Engineering Research Institute, Durgapur, India for constant support in completing this research work. The authors, also acknowledge, with thanks, the Science and Engineering Research Board, Department of Science and Technology, New Delhi, India for providing financial support (SERB sanction order no. SB/S3/MMER/0035/2014 dated 22-05-2014) to carry out this work.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Mandal, N., Doloi, B. & Mondal, B. Surface Roughness Prediction Model using Zirconia Toughened Alumina (ZTA) Turning Inserts: Taguchi Method and Regression Analysis. J. Inst. Eng. India Ser. C 97, 77–84 (2016). https://doi.org/10.1007/s40032-015-0189-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40032-015-0189-6