Abstract

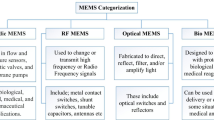

Microelectromechanical systems (MEMS) are a technology that allows engineers to create small, integrated devices with electrical and mechanical components to perform tasks carried out by macroscopic systems. MEMS devices are interfaces of the digital world (computer) and the analog world (our surroundings) with the capability of sensing and controlling. System-integrated chip technology is used to make these devices. The main advantages of MEMS are lightweight, ease of fabrication, reduced size, low-power operation, and the possibility of electrical and electronic device interaction. These MEMS devices find applications in biomedical fields such as detection, analysis, diagnosis, therapeutics, drug delivery, cell culture, microsurgery, and genome synthesis. This review paper discusses recent MEMS research, emphasising biomedical applications and advances. This paper includes functional components, technologies involved in manufacturing, and current trends in Bio-MEMS devices. This study discusses the Bio-MEMS device’s accuracy, design problems, prospective applications, and new possibilities.

Similar content being viewed by others

References

J. Putrino, G. Keating, A. Martyniuk, M. Faraone, L. Dell, Chemical and biological sensors based on microelectromechanical systems, in Nanomaterials: science and applications. (Pan Stanford Publ. Pte Ltd, Singapore, 2016), pp.107–145

N.S. Shanbhag, P.P. Patil, Bio-microelectromechanical systems: a novel approach for drug targeting in chronic diseases. New Horiz. Transl. Med. 36, 265–271 (2017)

L. Yunjia, Microelectromechanical systems (MEMS), in Material-integrated intelligent systems: technology and applications. (Wiley, New York, NY, USA, 2016), pp.83–105

M. Rafiee, P. Khatibi, G. Zehetbauer, A review of the most important failure, reliability and nonlinearity aspects in the development of microelectromechanical systems (MEMS). Microelectron. Int. 34(1), 9–21 (2017)

P. Bergveld, The challenge of developing microTAS (Springer, Dordrecht, 1955), pp.3745–3770

G. Li, X. Han, W. Sun, Y. Cheng, D. Li, A touch mode MEMS capacitance diaphragm gauge. Meas. Sens. 18, 100171 (2021)

X. Han, M. Xu, G. Li, H. Yan, Y. Feng, D. Li, Design and experiment of a touch mode MEMS capacitance vacuum gauge with square diaphragm. Sens. Actuat. A Phys. 313, 112154 (2020)

M. Xu et al., Design and fabrication of an absolute pressure MEMS capacitance vacuum sensor based on silicon bonding technology. Vacuum 186, 110065 (2021)

K. Kishore, S.S. Kumar, R. Mukhiya, S. Ali Akbar, High-resolution current mode interface for MEMS piezoresistive pressure sensor. AEU - Int. J. Electron. Commun. 134, 153707 (2021)

T. Grzebyk, K. Turczyk, P. Szyszka, A. Górecka-Drzazga, J. Dziuban, Pressure control system for vacuum MEMS. Vacuum 178, 109452 (2020)

A. Casillas, M. Modera, M. Pritoni, Using non-invasive MEMS pressure sensors for measuring building envelope air leakage. Energy Build. 233, 110653 (2021)

W. Zhang et al., Research on the influence of hydrostatic pressure on the sensitivity of bionic cilia MEMS vector hydrophone. Measurement 191, 110606 (2022)

R. Krisper, J. Lammer, Y. Pivak, E. Fisslthaler, W. Grogger, The performance of EDXS at elevated sample temperatures using a MEMS-based in situ TEM heating system. Ultramicroscopy 234, 113461 (2022)

V.F. Paes, B.A. Mueller, P.B. Costa, R.A. Rafael, M.P. Porto, Calibration uncertainty of MEMS thermopile imagers for quantitative temperature measurement. Infrared Phys. Technol. 120, 103978 (2022)

C.C. Cheng, L.H. Fang, H. Duan, C.C. Chen, T.K. Chung, A MEMS room-temperature resettable thermomagnetic-track-guided magnetic-bead manipulation integrated with magnetoresistive sensing for bead-motion monitoring. Sens. Actuat. A Phys. 332, 113087 (2021)

U. Zaghloul, B. Bhushan, G. Papaioannou, F. Coccetti, P. Pons, R. Plana, Nanotribology-based novel characterization techniques for the dielectric charging failure mechanism in electrostatically actuated NEMS/MEMS devices using force–distance curve measurements. J. Colloid Interface Sci. 365(1), 236–253 (2012)

J. Xu et al., Fabrication of ZnO nanorods and Chitosan@ZnO nanorods on MEMS piezoresistive self-actuating silicon microcantilever for humidity sensing. Sensors Actuators B Chem. 273, 276–287 (2018)

A.S. Hassan, V. Juliet, C.J.A. Raj, MEMS based humidity sensor with integration of temperature sensor. Mater. Today Proc. 5(4), 10728–10737 (2018)

M.T. Jan, F. Ahmad, N.H.B. Hamid, M.H.B.M. Khir, M. Shoaib, K. Ashraf, Experimental investigation of temperature and relative humidity effects on resonance frequency and quality factor of CMOS-MEMS paddle resonator. Microelectron. Reliab. 63, 82–89 (2016)

V.P.J. Chung, M.C. Yip, W. Fang, Resorcinol–formaldehyde aerogels for CMOS-MEMS capacitive humidity sensor. Sens. Actuat. B Chem. 214, 181–188 (2015)

B. Zhang et al., The principle and elimination of shadow image in the scanning image of the lidar based on MEMS mirror. Infrared Phys. Technol. 116, 103761 (2021)

T. Wenzel, R. Rettig, Design of MEMS microphone protective membranes for continuous outdoor applications. Appl. Acoust. 183, 108304 (2021)

A. Novak, P. Honzík, Measurement of nonlinear distortion of MEMS microphones. Appl. Acoust. 175, 107802 (2021)

A. Fawzy, A. Magdy, A. Hossam, A piezoelectric MEMS microphone optimizer platform. Alexandria Eng. J. 61(4), 3175–3186 (2022)

D. Faraci, A. Ghisi, S. Adorno, A. Corigliano, Top-down, multi-scale numerical simulation of MEMS microphones under guided free fall tests. Microelectron. Reliab. 121, 114129 (2021)

M.M. Zirkohi, Adaptive backstepping control design for MEMS gyroscope based on function approximation techniques with input saturation and output constraints. Comput. Electr. Eng. 97, 107547 (2022)

S. Luo, G. Yang, J. Li, H.M. Ouakad, Dynamic analysis, circuit realization and accelerated adaptive backstepping control of the FO MEMS gyroscope. Chaos. Solit. Fract. 155, 111735 (2022)

J. Jia et al., Overview and analysis of MEMS Coriolis vibratory ring gyroscope. Measurement 182, 109704 (2021)

H. Din, F. Iqbal, B. Lee, Mode ordering of single-drive multi-axis MEMS gyroscope for reduced cross-axis sensitivity. Sens. Actuat A Phys. 332, 113145 (2021)

S. Tariq, B. Bakhtawar, T. Zayed, Data-driven application of MEMS-based accelerometers for leak detection in water distribution networks. Sci. Total. Environ. 809, 151110 (2022)

A. Prato, F. Mazzoleni, G. D’Emilia, A. Gaspari, E. Natale, A. Schiavi, Metrological traceability of a digital 3-axis MEMS accelerometers sensor network. Measurement 184, 109925 (2021)

N.F. Morozov, D.A. Indeitsev, V.S. Igumnova, A.V. Lukin, I.A. Popov, L.V. Shtukin, Nonlinear dynamics of mode-localized MEMS accelerometer with two electrostatically coupled microbeam sensing elements. Int. J. Non. Linear. Mech. 138, 103852 (2022)

M. Chen, R. Zhu, Y. Lin, Z. Zhao, L. Che, Analysis and compensation for nonlinearity of sandwich MEMS capacitive accelerometer induced by fabrication process error. Microelectron. Eng. 252, 111672 (2022)

S. Liu, H. Liang, B. Xiong, An out-of-plane electromagnetic induction based resonant MEMS magnetometer. Sens. Actuat. A Phys. 285, 248–257 (2019)

G. Laghi et al., Torsional MEMS magnetometer operated off-resonance for in-plane magnetic field detection. Sens. Actuat. A Phys. 229, 218–226 (2015)

S. Dellea et al., Off-resonance operation of in-plane torsional MEMS magnetometers. Procedia Eng. 87, 819–822 (2014)

H. Qu, C.-L. Dai, CMOS MEMS fabrication technologies and devices. Micromachines. 7(1), 14 (2016)

G. Langfelder and A. Tocchio, “Microelectromechanical systems integrating motion and displacement sensors,” in Smart Sensors MEMS Intell. Sens. Devices Microsystems Ind. Appl. Second Ed., pp. 395–428, 2018

T. Kavallaris, N.I. Suzuki, Micro-electro-mechanical-systems (MEMS). In non-local partial differential equations for engineering and biology: mathematical modeling and analysis. Math. Model Anal. 31, 3–63 (2018)

T. Anjanappa, M. Datta, K. Song, Sensors and actuators (CRC Press, New Jersey, 2017), pp.11–16

D.T.H. Giang, N.H. Duc, G. Agnus, T. Maroutian, P. Lecoeur, Fabrication and characterization of PZT string based MEMS devices. J. Sci. Adv. Mater. Dev. 1(2), 214–219 (2016)

W. Yao and R. Peddi, “Customizable silicone materials for MEMS and semiconductor packages,” Proc. IEEE/CPMT Int. Electron. Manuf. Technol. Symp., vol. 2016-November, Nov. 2016.

Z. Liang, J. Guo, D. Fan, Manipulation, assembling, and actuation of nanomotors by electric tweezers. Robot. Syst. Auton. Platforms 1, 3–28 (2019)

L. Huang, P. Zhao, F. Liang, W. Wang, Single-cell 3D electro-rotation. Methods Cell Biol. 148, 97–116 (2018)

C. Chircov, A.M. Grumezescu, Microelectromechanical systems (MEMS) for biomedical applications. Micromachines. 13(2), 164 (2022)

V. Gaudin, “Receptor-based electrochemical biosensors for the detection of contaminants in food products,” Electrochem. Biosens, pp. 307–365, 2019.

P. Pan, W. Wang, C. Ru, Y. Sun, X. Liu, MEMS-based platforms for mechanical manipulation and characterization of cells. J. Micromechanics Microengineering 27(12), 123003 (2017)

A. Martinez-Rivas, G.K. González-Quijano, S. Proa-Coronado, C. Séverac, E. Dague, Methods of micropatterning and manipulation of cells for biomedical applications. Micromachines 8(12), 347 (2017)

W. Wang and S. A. Soper, “Bio-MEMS : Technologies and Applications,” Bio-MEMS, Dec. 2006.

O. Auciello et al., Materials science and fabrication processes for a new MEMS technology based on ultrananocrystalline diamond thin films. J. Phys. Condens. Matter 16(16), R539 (2004)

Y. Long, Z. Liu, and F. Ayazi, “4H-silicon carbide as an acoustic material for MEMS,” IEEE Trans. Ultrason. Ferroelectr. Freq. Control, 2023.

D. José Horst, P. Paulo Andrade Junior, R. De Almeida Vieira, P. Paulo de Andrade Junior, C. Adriano Duvoisin, and R. de Almeida Vieira, “Fabrication of Conductive Filaments for 3D-printing: Polymer Nanocomposites Gestão do conhecimento e da inovação em organizações View project Assessing the Lignin Fraction Extracted from Brazilian Energy Crops View project Fabrication of Conductive Filaments for 3D-printing: Polymer Nanocomposites,” 2020.

D. Qin, Y. Xia, J. A. Rogers, R. J. Jackman, X.-M. Zhao, and G. M. Whitesides, “Microfabrication, Microstructures and Microsystems,” pp. 1–20, 1998.

S.H. Kenawy, A.M. Khalil, Advanced ceramics and relevant polymers for environmental and biomedical applications. Bioint. Res. Appl. Chem. 10(4), 5747–54 (2020)

Z. Zhao et al., Achieving high contact-electrification charge density on inorganic materials. Nano Energy 114, 108616 (2023)

L. Niu, X. Sun, Y. Yang, X. Yuan, H. Tong, Synergistic effect of graphene on improving laser sealing performance of inorganic glass solder. J. Mater. Sci. Mater. Electron. 34(12), 1–10 (2023)

J. Hong et al., Large scale terahertz sensor array module with antenna coupled microbolometers on glass substrate with sigma delta ADC readout ASIC, IEEE Trans. Terahertz Sci. Technol., 2023.

M. Sawane, M. Prasad, MEMS piezoelectric sensor for self-powered devices: a review. Mater. Sci. Semicond. Process. 158, 107324 (2023)

M.T. Chorsi et al., Piezoelectric biomaterials for sensors and actuators. Adv. Mater. 31(1), 1802084 (2019)

Z. Dong et al., Microfabrication of functional polyimide films and microstructures for flexible MEMS applications. Microsyst. Nanoeng. 9(1), 1–22 (2023)

M.G. Thompson et al., Identification, characterization, and application of a highly sensitive lactam biosensor from pseudomonas putida. ACS Synth. Biol. 9(1), 53–62 (2020)

I. Voiculescu, A.N. Nordin, Acoustic wave based MEMS devices for biosensing applications. Biosens. Bioelectron. 33(1), 1–9 (2012)

J.X.J. Zhang, Plasmonic MEMS in biosensing and imaging (Springer, London, 2023), pp.107–181

V. Suresh, B. Rajesh Kumar, Design of piezoresistive pressure sensor for enhancing stress of MEMS cantilever. Meas. Sens. 25, 100637 (2023)

Y. Liu, Y. Tian, C. Lin, J. Miao, X. Yu, A monolithically integrated microcantilever biosensor based on partially depleted SOI CMOS technology. Microsystems Nanoeng. 9(1), 1–11 (2023)

S. Dzyadevych, N. Jaffrezic-Renault, Conductometric biosensors. Biol. Identif. DNA Amplif. Seq. Opt. Sensing, Lab-On-Chip Portable Syst. 3, 153–193 (2014)

S.P. Mohanty, E. Koucianos, Biosensors: a tutorial review. IEEE Potentials 25(2), 35–40 (2006)

D.S. Eddy, D.R. Sparks, Application of MEMS technology in automotive sensors and actuators. Proc. IEEE 86(8), 1747–1755 (1998)

S. Bütefisch, V. Seidemann, S. Büttgenbach, Novel micro-pneumatic actuator for MEMS. Sensors Actuators A Phys. 97–98, 638–645 (2002)

H. Ernst, A. Jachimowicz, G.A. Urban, High resolution flow characterization in Bio-MEMS. Sensors Actuators A Phys. 100(1), 54–62 (2002)

K. Bespalova, T. Nieminen, A. Gabrelian, G. Ross, M. Paulasto-Kröckel, In-plane AlN-based actuator: toward a new generation of piezoelectric MEMS. Adv. Electron. Mater. 9, 2300015 (2023)

B. Sotoudeh, S. Afrang, S. Ghasemi, O.R. Afrang, Design and simulation of a wide-range variable MEMS capacitor using electrostatic and piezoelectric actuators. Microsyst. Technol. 2023, 1–13 (2023)

M.J. Ramsay, W.W. Clark, Piezoelectric energy harvesting for bio-MEMS applications. Proc. SPIE 4332, 429–438 (2001)

M.I. Hossain, M.S. Zahid, M.A. Chowdhury, M.M. Maruf Hossain, N. Hossain, MEMS-based energy harvesting devices for low-power applications–a review. Results Eng. 19, 101264 (2023)

H. Toshiyoshi, S. Ju, H. Honma, C.H. Ji, H. Fujita, MEMS vibrational energy harvesters. Taylor Fr. 20(1), 124–143 (2019)

C. Wang, L. Taherabadi, G. Jia, M. Madou, Y. Yeh, B. Dunn, C-MEMS for the manufacture of 3D microbatteries. Electrochem. Solid-State Lett. 7(11), A435 (2004)

L.J. Tang, M.H. Wang, H.C. Tian, X.Y. Kang, W. Hong, J.Q. Liu, Progress in research of flexible MEMS microelectrodes for neural interface. Micromachines 8(9), 281 (2017)

M. Preeti, K. Guha, K.L. Baishnab, K. Dusarlapudi, K. Narasimha Raju, Low frequency MEMS accelerometers in health monitoring–A review based on material and design aspects. Mater. Today Proc. 18, 2152–2157 (2019)

A. Albarbar, A. Badri, J.K. Sinha, A. Starr, Performance evaluation of MEMS accelerometers. Measurement 42(5), 790–795 (2009)

X. Gong, Y.C. Kuo, G. Zhou, W.J. Wu, W.H. Liao, An aerosol deposition based MEMS piezoelectric accelerometer for low noise measurement. Microsyst. Nanoeng. 9(1), 1–13 (2023)

M. Rudra Naik, U.N. Kempaiah, Directional optimization of MEMS piezoelectric hydrophone for underwater application. Mater. Today Proc. 5(1), 823–829 (2018)

S. Wu et al., MEMS co-vibration combined hydrophone. Measurement 208, 112463 (2023)

T. S. K. Beulah Sujan, Bio-MEMS cantilever sensor design and analysis for detecting multiple diseases, in IEEE International Conference on Circuits and Systems, 2017.

Z. H. Xin, H. Y. Sun, and D. B. Wang, A High-performance Dual-channel MEMS Microwave Power Sensor with Cantilever Beam. IEEE Sens. J. 2023

S. Gorthi, A. Mohanty, A. Chatterjee, Cantilever beam electrostatic MEMS actuators beyond pull-in. J. Micromechan. Microeng. 16(9), 1800 (2006)

C.-Y. Tsai, N.-C. Sue, Review of MEMS-based drug delivery and dosing systems. Sens. Actuat. A Phys. 134(2), 555–564 (2007)

N.T. Nguyen, X. Huang, T.K. Chuan, MEMS-micropumps: a review. J. Fluids Eng. 124(2), 384–392 (2002)

H. Gensler, R. Sheybani, P. Y. Li, R. Lo Mann, and E. Meng, “An implantable MEMS micropump system for drug delivery in small animals. Biomed. Microdevices, 14(3)

A. Nisar, N. Afzulpurkar, B. Mahaisavariya, A. Tuantranont, MEMS-based micropumps in drug delivery and biomedical applications. Sen. Actuators B Chem. 130(2), 917–942 (2008)

J.M. Bustjllo, R.T. Howe, R.S. Muller, Surface micromachining for microelectromechanical systems. Proc. IEEE 86(8), 1552–1573 (1998)

M. Keshavarzi, J. Yavand Hasani, Design and optimization of fully differential capacitive MEMS accelerometer based on surface micromachining. Microsyst. Technol. 25(4), 1369–1377 (2019)

H. Feng et al., Design and simulation of a low pull-in voltage RF MEMS switch in series for X-band, in 2023 IEEE 3rd International Conference on Information Technology, Big Data and Artificial Intelligence, pp. 744–750, May 2023.

S. Kim, H.G. Yeo, J. Ryu, H. Choi, Fabrication of surface-micromachined circular piezoelectric micromachined ultrasonic transducers with various etching holes using XeF2 and simulation of their vibrational characteristics. Sens. Actuat. A Phys. 351, 114159 (2023)

J. Singh, R. Kant, A. Nimesh, N. Katiyar, and S. Bhattacharya, “Evaluating electrochemical micromachining capabilities for industrial applications: a review. Taylor Fr., 2023.

A. R. Kolahdouz-Moghaddam, S. Nabavi, and F. Nabki, Temperature dependence modeling and thermal sensitivity reduction of bulk micromachined silicon MEMS Lamé Resonators. J. Microelectromechanical Syst., 2023.

F. Gaiseanu, “Analytical Modeling for Fabrication of Biomedical Pressure Sensors by Bulk Micromachining Technology: Silicon Capacitive Pressure Sensors,” IGI-Global, pp. 1–19, Jan. 1AD.

N. Maheshwari, G. Chatterjee, V. R.-J. ISSS, (2014) A technology overview and applications of bio-MEMS,” Citeseer. 3(2): 39–59

J. P. Dudeja, Micromachining of Polymeric Bio-MEMS with Lasers. IJCRT, 6(4) 2018.

F.P.W. Melchels, J. Feijen, D.W. Grijpma, A review on stereolithography and its applications in biomedical engineering. Biomaterials 31(24), 6121–6130 (2010)

A.A.Z.S. Amin Yavaria, M. Croesa, B. Akhavan, F. Jahanmarda, C.C. Eigenhuis, S. Dadbakhshe, C. Vogely, M.M. Bilek, A.C. Fluit, C.H.E. Boel, B.C.H. van der Wala, T. Vermonden, H. Weinans, Layer by layer coating for bio-functionalization of additively manufactured meta-biomaterials. Addit. Manuf. 32, 100991 (2020)

G. Ciuti, L. Ricotti, A. Menciassi, P. Dario, MEMS sensor technologies for human centred applications in healthcare, physical activities, safety and environmental sensing: a review on research activities in Italy. Sensors 15(3), 6441–6468 (2015)

G. Zhang, M. Liu, N. Guo, W. Zhang, Design of the MEMS piezoresistive electronic heart sound sensor. Sensors 16(11), 1728 (2016)

S.I.K. Uchiyama, M.T. Sawazaki, H. Shimizu, Development of a Bio-MEMS for evaluation of dioxin toxicity by immunoassay method. Sens. Actuat. B Chem. 103(1–2), 200–205 (2004)

V.R.E.Y. Chow, S.P. Sanghani, Emerging research in wireless and MEMS for medical applications. Wirel. MEMS Networks Appl. 1, 153–175 (2017)

U. F. & H. W. Shengbo Sang, “Concept of a Microfluidics and Tunneling Effect-Based BioMEMS to Detect Cells, in: World Congress on Medical Physics and Biomedical Engineering, 7-12, 2009, Munich, Germany: Vol. 25/8 Micro-and Nanosystems in Medicine, Active Implants, pp. 144–147, 2009.

H. Sung Keun, Y. Jin, H. Leeb, M.B. Sung-SikYuna, G. Jong, Fabrication of a bio-MEMS based cell-chip for toxicity monitoring. Biosens. Bioelectron. 22(8), 1586–1592 (2007)

V. Giorgio De Pasquale, L. Zappulla, L. Scaltrito, Numerical and experimental evaluation of SLA polymers adhesion for innovative bio-MEMS. Mater. Today. 7(1), 572–577 (2019)

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Pandey, Y., Singh, S.P. Recent Advances in Bio-MEMS and Future Possibilities: An Overview. J. Inst. Eng. India Ser. B 104, 1377–1388 (2023). https://doi.org/10.1007/s40031-023-00924-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40031-023-00924-w