Abstract

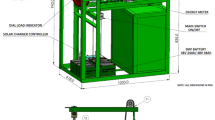

A walk-behind type electric vertical conveyor reaper (E-VCR) of cutting width 600 mm, powered by a 800 W 48 V DC motor using four lead–acid batteries of 12 V 18 Ah for carrying out cutting of crop and a 24 V 350 W DC motor using two lead–acid batteries of 12 V 12 Ah for propelling was developed. Its performance was evaluated and compared with a self-propelled fossil fuel operated vertical conveyor reaper (VCR) while harvesting in test fields having matured paddy crop with moisture content of grain and straw as 20 to 32% and 68 to 75%, respectively. The field capacity, cutting efficiency and header loss with E-VCR were found to be 0.06 ha/h, 95% and 2.05%, respectively, as compared to 0.20 ha/h, 98% and 2.42% with VCR. The E-VCR had less drudgery than VCR due to reduction in noise and hand vibration by 8% and 50%, respectively. Manpower required for harvesting with E-VCR, VCR and manually with sickle were 16 man-h/ha, 5 man-h/ha and 185 man-h/ha, respectively, leading to a cost of harvesting per hectare as Rs. 2904, Rs. 2318 and Rs. 8094. Annual use below 2.9 ha for E-VCR and 5.2 ha for VCR was found uneconomical for carrying out harvesting.

Similar content being viewed by others

References

A.C. Varshney, P.S. Tiwari, S. Narang, C.R. Mehta, Data book for agricultural machinery design, Central Institute of Agricultural Engineering, Bhopal, 339–391(2004)

A. Nadeem, D. Gee-Clough, Field performance evaluation of rice reaper. Agric. Mech. Asia Afr. Latin Am. 14, 35–40 (1983)

M.M. Badr, Comparative study between some different combine sizes in respect to unit plot area. M. Sc. Thesis. Agric. Eng. Dept. Faculty of Agric. Zagazig Univ. Egypt (2005)

L.P. Singh, V.R. Vagadia, K.K. Jain, A.H. Memon, Evaluation and improvement in design of self-propelled vertical conveyor reaper. Agri Mech. Asia Afr. Latin Am. 39(2), 34–38 (2008)

A. Debnath, N.S. Chouhan, Field performance and economic feasibility of self-propelled vertical conveyor reaper (vcr) for harvesting of rice in West Sikkim and a technological strategy for mitigation of air pollution through crop residue burning in India. Nat. Environ. Pollut. Technol. 19(2), 521–538 (2020)

B.C. Parida, Evaluation, constraints and acceptability of different types of vertical conveyor reaper for harvesting rice in coastal Orissa, India. Agric. Mech. Asia Afr. Latin Am. 39(1), 29–32 (2008)

M.M. Rahman, M.M. Hossain, A.K.M.S. Islam, Modification and performance evaluation of self propelled reaper. J. Inst Eng Bangladesh Agric. Eng. Div. 31(1), 23–28 (2004)

A.U. Sahoo, H. Raheman, Development of an electric reaper: a clean harvesting machine for cereal crops. Clean Technol. Environ. Policy 22, 955–964 (2020)

IS 11467, Test code for cereal harvesting machine, Indian Standard Institution, New Delhi (1985)

RNAM Test code and procedure for harvesting machines, Tech ser 12, 207–227 (1983)

IS 12180–1, Tractors and machinery for agriculture and forestry—Noise measurement - Method of test, Part 1: Noise at the operator's position - Survey method, Bureau of Indian Standards, New Delhi (2000)

IS 12180–2, Tractors and machinery for agriculture and forestry – Noise measurement – Method of test, Part 2: Noise emitted when in motion. Bureau of Indian Standards, New Delhi (2000)

ISO 5349–1, Mechanical vibration measurement and evaluation of human exposure to hand-transmitted vibration (2001)

IS: 9164, Guides for estimating cost of farm machinery operation. Bureau of Indian Standards, New Delhi (1972)

P. Dutt, J. Prasad, Modification and evaluation of self-propelled reaper for harvesting soybean. Agric. Mech. Asia Afr Latin Am 3, 43–46 (2002)

D. Monarca, P. Biondi, M. Cecchini, M. Santi, M. Guerrieri, A. Colantoni, F. Colopardi, Transmission of vibrations from portable agricultural machinery to the Hand-Arm System (HAV): risk assessment and definition of exposure time for daily action and exposure limits, innovation technology to empower safety, health and welfare in agriculture and agro-food systems, International Conference: September 15–17, 2008 Ragusa, Italy (2008).

R.M. Nester, Occupational safety & health administration: building partnerships(OSHA-1910.95). Am. Assoc. Occup. Health Nurses J. 44(10), 493–499 (1996)

Funding

The financial support received from the National Initiative for Design Innovation (NID) sponsored by the Ministry of Human Resource Development, Govt. of India is sincerely acknowledged.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Sahoo, A.U., Raheman, H. Performance of an Electric Vertical Conveyor Reaper vis-à-vis Conventional Reaper for Harvesting of Paddy Crop. J. Inst. Eng. India Ser. A 103, 239–246 (2022). https://doi.org/10.1007/s40030-021-00584-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40030-021-00584-3