Abstract

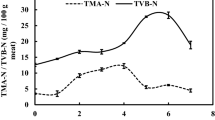

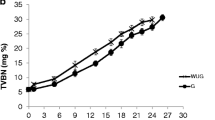

Careful handling of fish and shellfish onboard at the vessel is of prime importance in order to maintain the freshness. Use of slurry ice for onboard fish storage allows rapid heat transfer as well as reduces damage to the product by conventional ice. In the present investigation, the effect of onboard chilling with conventional ice and slurry ice on the quality of squid was evaluated. Samples stored at different time intervals (7th and 11th day) were collected and analyzed for their biochemical, textural and microbiological quality characteristics. Use of slurry ice, immediately after catch of squid reduced the formation of nitrogenous substances as well as the rate of pH increase during storage. Total volatile base nitrogen, tri methyl amine nitrogen and thio-barbituric acid values were within the acceptable limit in both the samples. Texture analysis showed higher hardness, springiness, gumminess and chewiness values for squid samples stored under slurry ice than the samples stored under conventional ice. Further, squid samples stored under slurry ice exhibited higher values of salt content. Microbiological analysis showed significant difference (p < 0.05) in psychrophilic counts of squid stored under slurry ice than the conventional iced ones.

Similar content being viewed by others

References

Sikorski ZE, Bonnie SP, Shahidi F (1994) Seafood proteins. Chapman & Hall, New York

Billiard F, Viard D (2002) Food safety and refrigeration. Join FAO/WHO global forum of food safety regulators, 28–30 January 2002, Marrakesh. http://www.iifiir.org/1endossiers.asp#2

Huidobro A, Lopez-Caballero M, Mendes R (2002) Onboard processing of deepwater pink shrimp (Parapenaeus longirostris) with liquid ice: effect on quality. Eur Food Res Technol 214:469–475

Pineiro C, Barros-Velazquezb J, Aubourg SP (2004) Effects of newer slurry ice systems on the quality of aquatic food products: a comparative review versus flake-ice chilling methods. Trends Food Sci Technol 15:575–582

Chapman L (1990) Making the grade ice slurries get top marks for quality products. Aust Fish 7:16–19

Sikorski ZE, Kolodziejska I (1986) The composition and properties of squid meat. Food Chem 20:213–224

AOAC (1998) Official methods of analysis, 17th edn. Association of Official Analytical Chemists, Washington, DC, USA

Conway EJ (1950) Micro-diffusion analysis and volumetric error. Lockwood and Son Ltd, London

Pope CG, Stevens MF (1939) The determination of amino nitrogen using a copper method. J Biochem 33:1070

Velankar NK, Govindan TK (1958) A preliminary study of the distribution of non protein nitrogen in some marine fishes and invertebrates. Proc Indian Acad Sci 47:202–209

Ironside JIM, Love RM (1958) Studies on protein denaturation in frozen fish—I: biological factors influencing the amount of soluble and insoluble protein present in the muscle of North Sea cod. J Sci Food Agric 9:597–599

BAM (2001) Bacteriological analytical manual, chapter 3, aerobic plate count. FDA. http://www.fda.gov/Food/FoodScienceResearch/LaboratoryMethods/ucm063346.htm

Koneman EW, Allen SD, Janda WM, Schreckenberger PC, Winn WC Jr. (1992) Colour Atlas and Textbook of Diagnostic Microbiology, 4th edn. J. B. Lippincott Company, Philadelphia

Stroud GD (2001) Squid. Torry advisory note 77

Losada V, Pineiro C, Barros-Velazquez J, Aubourg S (2005) Inhibition of chemical changes related to freshness loss during storage of horse mackerel (Trachurus trachurus) in slurry ice. Food Chem 93:619–625

Campos CA, Rodrigueza GA, Losadac V, Aubourgc SP, Barros-Velazqueza J (2005) Effects of storage in ozonised slurry ice on the sensory and microbial quality of sardine (Sardina pilchardus). Int J Food Microbiol 103:121–130

Ruiz-Capillas C, Moral A (2001) Correlation between biochemical and sensory quality indices in hake stored in ice. Food Res Int 34:441–447

Binsi PK, Shamasundar BA, Dileep AO (2007) Physico-chemical and functional properties of proteins from green mussel (Perna viridis) during ice storage. J Sci Food Agric 87:245–254. doi:10.1002/jsfa.2706

Simeonidou S, Govaris A, Vareltzis K (1998) Quality assessment of seven Mediterranean fish during storage on ice. Food Res Int 30(7):479–484

Erkan N, Ozden O, Alakavuk DU, Yildirim SY, Lnugur M (2006) Spoilage and shelf life of sardines (Sardina plichardus) packed in modified atmosphere. J Eur Food Res Technol 222:667–673

Lakshmanan PT (2000) Fish spoilage and quality assessment. In: Kandoran MK, Thomas M, Mathew PT (eds) Iyer TSG. Quality assurance in seafood processing Society of Fisheries Technologists, Cochin, pp 26–40

Rodriguez O, Torres M, Pineiro C, Losada V, Aubourg SP, Barros-Velazquez J (2003) Extension of shelf life and microbial activity of horse mackerel (Trachurus trachurus) stored in flow ice. In: Novas perspectivas sobre conservação, processamento equalidade de alimentos. Actas do 68 encontro de química de alimentos, vol 1, pp 58–66

Connell JJ (1995) Quality deterioration and extrinsic quality defects in raw material. In: Ltd Fishing News Books (ed) Control of Fish Quality, 4th. Survey, U.K., pp 31–35

Losada V, Barros-Velazquezb J, Aubourg SP (2007) Rancidity development in frozen pelagic fish: influence of slurry ice as preliminary chilling treatment. LWT 40:991–999

Smith J, Hardy R, McDonald I, Templeton J (1980) The storage of herring (Clupea harengus) in ice, refrigerated sea water and at ambient temperature chemical and sensory assessment. J Sci Food Agric 31:375–385

Srikar L, Khuntia B, Reddy G, Srinivasa B (1993) Influence of storage temperature on the quality of salted mackerel (Rastrelliger kangurta) and pink perch (Nemipterus japonicus). J Sci Food Agric 63:319–322

Losada V, Pineiro C, Barros-Velazquez J, Aubourg S (2004) Effect of slurry ice on chemical changes related to quality loss during European hake (Merluccius merluccius) chilled storage. Eur Food Res Technol 219:27–31

Nollet LML, Toldra F (2010) Hand book of sea food and sea food products analysis. Taylor and Francis Group, Boca Raton

Radocaj OF, Dimic EB, Vujasinovic VB (2011) Optimization of the texture of fat-based spread containing hull-less pumpkin (Cucurbita pepo L.) seed press-cake. Acta Period Technol 42:1–288

Aubourg SP, Losada V, Prado M, Miranda J, Barros-Velázquez J (2007) Improvement of the commercial quality of chilled Norway lobster (Nephrops norvegicus) stored in slurry ice: effects of a preliminary treatment with an antimelanosic agent on enzymatic browning. Food Chem 103:741–748

Acknowledgements

The authors express sincere thanks to Dr. C. N. Ravishankar, Director, ICAR-CIFT, Cochin for the encouragement and granting permission to publish this research article.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Significance statement Slurry ice system lowers the temperature quickly as a result of quick chilling compared to conventional ice. The application of slurry ice storage system for squid samples reduced the rate of microbiological and biochemical degradation mechanisms compared to conventional ice. Application of slurry ice may be beneficial when food quality and safety are concerned which will allow automation and hygienic handling of seafood onboard.

Rights and permissions

About this article

Cite this article

Narasimha Murthy, L., Phadke, G.G., Jeyakumari, A. et al. Biochemical, Textural and Microbiological Quality of Squid Stored Under Conventional and Slurry Ice During Onboard Fishing. Proc. Natl. Acad. Sci., India, Sect. B Biol. Sci. 88, 1647–1653 (2018). https://doi.org/10.1007/s40011-017-0916-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40011-017-0916-2