Abstract

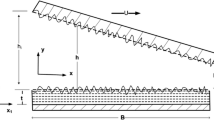

This paper analyses the thermal and roughness effects on different characteristics of an infinitely long tilted pad slider bearing considering heat conduction through both the pad and slider. The roughness is assumed to be stochastic, Gaussian randomly distributed. Density and viscosity are assumed to be temperature dependent. The irregular domain of the fluid due to roughness is mapped to a regular domain so that the numerical method can be easily applied. The modified Reynolds equation, momentum equation, continuity equation, energy equation and the heat conduction equations on the pad and slider are solved simultaneously using finite difference method to yield various bearing characteristics. The solutions with respect to different pad and slider boundary conditions are elaborated through tables and figures.

Similar content being viewed by others

Abbreviations

- B :

-

Bearing width

- c :

-

Specific heat of lubricant

- E c :

-

Eckert number

- E :

-

Expected value operator

- F :

-

Frictional drag force

- h :

-

Nominal film thickness

- h i :

-

Nominal film thickness at the leading edge

- h o :

-

Nominal film thickness at the trailing edge

- h 1 :

-

Heat transfer coefficient

- H :

-

The height of the film for rough surface

- k 0 :

-

Thermal conductivity of the lubricant

- k p :

-

Thermal conductivity of the stationary solid

- k s :

-

Thermal conductivity of the moving solid

- m :

-

ho/hi

- p :

-

Film pressure

- P e :

-

Peclet number

- p i :

-

Inlet pressure

- P r :

-

Prandtl number

- T :

-

Lubricant temperature

- T 1 :

-

Pad temperature

- T 2 :

-

Slider temperature

- T a :

-

Ambient temperature

- T i :

-

Inlet temperature

- T avg :

-

Average temperature across the film

- t p :

-

Nominal pad thickness

- t s :

-

Nominal slider thickness

- u :

-

Fluid velocity in the direction of sliding

- U:

-

Velocity of the moving surface

- v :

-

Velocity in the direction of y coordinate

- x :

-

Coordinate in the direction of sliding

- y :

-

Coordinate in the direction of film thickness

- x 1, y 1 :

-

Coordinate system for the pad

- x 2, y 2 :

-

Coordinate system for the slider

- x ′ , y ′ :

-

Transformed coordinate system for the fluid film

- x ′1 , y ′1 :

-

Transformed coordinate system for the pad

- x ′2 , y ′2 :

-

Transformed coordinate system for the slider

- W :

-

Load carrying capacity of the bearing

- β:

-

Temperature coefficient in viscosity formula

- δ:

-

Random distributions of roughness

- ε:

-

Random variable

- λ :

-

Temperature coefficient in density formula

- μ:

-

Viscosity of the lubricant

- μa :

-

Ambient viscosity

- μ avg :

-

Average viscosity across the film

- ρ:

-

Density of the lubricant

- ρa :

-

Ambient density

- ρ avg :

-

Average density across the film

- σ2 :

-

Variation of roughness

- Super script *:

-

Depicts a corresponding non dimensional quantity and bar above a variable depicts the corresponding expected value

References

Tzeng ST, Saible H (1967) Surface roughness effect on slider bearing lubrication. ASME Trans 10:334–338

Christensen H, Tonder K (1969) Tribology of roughness: stochastic models of hydrodynamic lubrication, SINTEF report 10/69-18, Trondheim

Christensen H (1969–1970) Stochastic models of hydrodynamic lubrication of rough surfaces. Proc Inst Mech Eng 184:1013–1022

Christensen H, Shukla JB, Kumar S (1975) Generalized Reynolds equation for stochastic lubrication and its application. J Mech Eng Sci 17(5):263–270

Dowson D, Hudson JD (1963) Thermohydrodynamic analysis of the infinite slider bearing: part I, the plane-inclined slider bearing. Inst Mech Eng Lubr Wear Conv 4:3141

Dowson D, Hudson JD (1963) Thermohydrodynamic analysis of the infinite slider bearing: part II, the parallel surface bearing. Inst Mech Eng Lubr Wear Conv 5:34–51

McCallion H, Yousif F, Lioyd T (1970) The analysis of thermal effects in a full journal bearing. Trans ASME J Lubr Technol 92:578–587

Ezzat H, Rohde SA (1973) Study of thermal effects in thermohydrodynamic performance of finite slider bearings. Trans ASME J Lubr Technol 95:298–307

Rohde SM, Kong OP (1975) A thermohydrodynamic analysis of finite slider bearing. Trans ASME J Lubr Technol 97:450–460

Gero LR, Ettles CM (1987) A three dimensional thermohydrodynamic finite element scheme for fluid film bearings. STLE Trib Trans 31:182–191

Rathish BVR, Rao PS, Sinha P (2001) A numerical study of performance of a slider bearing with heat conduction to the pad. Finite Elem Anal Des 37:533–547

Ramesh J, Majumdar C, Rao NS (1997) Thermohydrodynamics analysis of submerged oil journal bearings considering roughness effects. J Trib 119:100–106

Chang L, Farnum C (1992) A thermal model for elastohydrodynamic lubrication of rough surfaces. Trib Trans 35:281–286

Huynh BP, Loe S (2004) Influence of location, number and shape of corrugations in slider bearings. Anziam J 45(3):C1017–C1038

Ozalp AA, Umur H (2006) Optimum surface profile design and performance evaluation of inclined slider bearings. Curr Sci 90:1480–1491

Prawal S, Getachew A (2009) THD analysis for slider bearing with roughness: special reference to load generation in parallel sliders. Acta Mech 207:11

Lebeck AO (1987) Parallel load support in the mixed friction regime, part I—the experimental data. ASME J Trib 109:189–195

Gururajan K, Prakash J (1999) Surface roughness effects in infinitely long porous journal bearing. J Trib 121:139–147

Acknowledgments

The authors would like to thank CV Raman International Fellowship for African Researchers for its financial support for the first author in the form of Visiting Fellowship at IIT Kanpur, India.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Adamu, G., Sinha, P. Thermal and Roughness Effects in a Tilted Pad Slider Bearing Considering Heat Conduction Through the Pad and Slider. Proc. Natl. Acad. Sci., India, Sect. A Phys. Sci. 82, 323–333 (2012). https://doi.org/10.1007/s40010-012-0046-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40010-012-0046-4