Abstract

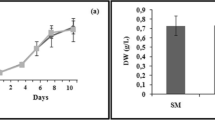

This study reports information on the small-scale mass production of spirulina utilizing low cost and locally available media under refined culture conditions in northern Mindanao, Philippines. A low-cost alternative culture medium was formulated using NPK 30-10-10 fertilizer as the main nutrient source, after which the optimum nutrient levels were first determined, followed by refinement of the culture conditions (i.e., salinity, aeration intensity, photoperiod, inoculum density, and inoculum growth phase). Furthermore, the proximate composition of the product, spirulina powder, was determined, and a cost-return analysis was performed. The optimum level for the NPK 30-10-10 fertilizer was found to be 1.0 mM N, which resulted in the highest biomass production of 0.750 ± 0.06 g L−1. The highest biomass and best growth indices were observed at 30 ppt salinity, 90 L h−1 aeration intensity, 24:0 L:D photoperiod, and 1.5 g L−1 inoculum density in the exponential phase. The spirulina powder produced was of good quality based on its proximate composition, with 62.87 ± 1.38% crude protein, 6.62 ± 0.05% minerals, 0.38 ± 0.01% crude fat, 3.91 ± 0.47% crude fiber, 14.84 ± 1.76% carbohydrate, 11.38 ± 0.02% moisture, and 314.24 ± 2.04 kcal 100 g−1 total digestible energy. The cost-return analysis showed that small-scale production is profitable, with a 65.22% return on investment and a payback period of 1.82 years. This small-scale production technology of spirulina can be adapted by local companies and cooperatives to spur local spirulina production in the country.

Similar content being viewed by others

References

Akhtar N, Ahmed MM, Hossain A, Jahan MAA, Akhter H (2014) Growth response of Spirulina platensis (nordst) geitler, in cabbage extract and anti-bacterial activities in different culture media. Bangladesh J Sci Ind Res 49(4):205–210

Andrade MR, Costa JAV (2007) Mixotrophic cultivation of microalga Spirulina platensis using molasses as organic substrate. Aquaculture 264:130–134

AOAC International (2016) Association of Official Analytical Chemists International. Official methods of analysis of the Association of AOAC International, 20th Edn. AOAC International, Rockville, Maryland, United States of America.

Araujo R, Calderon VF, Lopez JS, Azevedo IC, Bruhn A, Fluch S, Tasende MG, Ghaderiardakani F, Llmjarv T, Lurans M, Monagail MM, Mangini PC, Rebours C, Stefansson T, Ullmann J (2021) Current status of the algae production industry in Europe: an emerging sector of the blue bioeconomy. Front Mar Sci 7(626389):1–6

Barlow J, Sims RC, Quinn JC (2016) Techno-economic and life-cycle assessment of an attached growth algal biorefinery. Bioresour Technol 220:360–368

Becker EW (1994) Microalgae biotechnology & microbiology. Cambridge University, Cambridge, pp 93–95

Belay A (2007) Spirulina (Arthrospira): production and quality assurance. Spirulina in human nutrition and health. CRC Press, pp 15–40

Bhat, O, Unpaprom Y, Ramaraj, R (2023) Effect of photoperiod and white LED on biomass growth and protein production by Spirulina. Mol Biotechnol: 1–9.

Birot R, Jouvencel DD, Raginel L, Rouille G (2012) From malnutrition to HIV: spirulina is an effective solution which continues to reveal its secrets. Field Actions Sci Rep Special Issue 5. 6

Chaiklahan R, Chirasuwan N, Siangdung W, Paithoonrangsarid K, Bunnag B (2010) Cultivation of Spirulina platensis using pig wastewater in a semi-continuous process. J Microbiol Biotechnol 20:609–614

Chen J, Wang Y, Benemann JR, Zhang X, Hu H, Qin S (2016) Microalgal industry in China: challenges and prospects. J Appl Phycol 28(2):715–725

Choi A, Kim SG, Yoon BD, Oh HM (2003) Growth and amino acid contents of Spirulina platensis with different nitrogen sources. Biotechnol Bioprocess Eng 8:368–372

Costa JAV, Freitas BCB, Rosa GM, Morales L, Morais MG, Mitchell BG (2019) Operational and economic aspects of spirulina-based biorefinery. Bioresour Technol 292:121946

Dianursanti I, Taurina Z, Indraputri CM (2018) Optimization growth of Spirulina platensis in bean sprouts extract medium with urea fertilizer for phycocyanin production as antioxidant. AIP Conf Proc 1933:030014

El-chaghaby AG, Rashad G, Abdel-kader SF, Rawash E, Abdul M (2019) Assessment of phytochemical components, proximate composition and antioxidant properties of Scenedesmus obliquus, Chlorella vulgaris and Spirulina platensis algae extracts. Egypt J Aquat Biol Fish 23(4):521–526

Faintuch BL, Sato S, Aquarone E (1991) Influence of the nutritional sources on the growth rate of cyanobacteria. Arch Biol Technol 34:13–30

FAO (2020) The state of world fisheries and aquaculture 2020. Sustainability in action. Rome, Italy. p 244

FAO (2021) Global seaweeds and microalgae production, 1950–2019. World aquaculture production indicator factsheet, food and agriculture organization of the United Nations, Rome, p 172

Fuentes J, Garbayo I, Cuaresma M, Montero Z, González-del-Valle M, Vílchez C (2016) Impact of microalgae-bacteria interactions on the production of algal biomass and associated compounds. Mar Drugs 14(5):100

Ghobadian S, Ganjidoost H, Ayati B, Soltani N (2015) Evaluation of the effects of aeration cycle and culture medium concentration on biomass qualitative and quantitative indices in microalga Spirulina as candidate for wastewater treatment. J Aquat Ecol 5(2):87–99

Gillor O, Harush A, Hadas O, Post AF, Belkin SA (2003) A Synechococcus P glnA: luxAB fusion for estimation of nitrogen bioavailability to freshwater cyanobacteria. Appl Environ Microbiol 69(3):1465–1474

Grobbelaar JU (2009) From laboratory to commercial production: a case study of a Spirulina (Arthrospira) facility in Musina. South Africa J Appl Phycol 21(5):523–527

Habib MAB, Parvin M, Huntington TC, Hasan MR (2008) A review on culture, production and use of Spirulina as food for humans and feeds for domestic animals and fish. FAO Fish Aquac Circ 33:1034

Higa T (2000) What is EM technology. EM World J 1:1–6

Hoffman J, Pate RC, Drennen T, Quinn JC (2017) Techno-economic assessment of micro-algae production systems. Algal Res 23:51–57

Illman AM, Scragg AH, Shales SW (2000) Increase in Chlorella strains calorific values when growth in low nitrogen medium. Enzyme Microb Technol 27:631–635

Kumari A, Pathak AK, Guria C (2015) Cost-effective cultivation of Spirulina platensis using NPK fertilizer. Agric Res 4:261–271

Lananan F, Abdul Hamid SH, Din WNS, Ali N, Khatoon H, Jusoh A, Endut A (2014) Symbiotic bioremediation of aquaculture wastewater in reducing ammonia and phosphorus utilizing effective microorganism (EM-1) and microalgae (Chlorella sp.). Int Biodeterior Biodegrad 95:127–134

Lee YK (1997) Commercial production of microalgae in the Asia-Pacific rim. J Appl Phycol 9(5):403–411

Liu C, Li LJ, Wu CY, Guo KN, Li JH (2016) Growth and antioxidant production of Spirulina in different NaCl concentrations. Biotechnol Lett 38:1089–1096

Lu YM, Xiang WZ, Wen YH (2011) Spirulina (Arthrospira) industry in Inner Mongolia of China: current status and prospects. J Appl Phycol 23(2):265–269

Madkour FF, Kamil AEW, Nasr HS (2012) Production and nutritive value of Spirulina platensis in reduced cost media. Egypt J Aquat Res 38(1):51–57

Martel A, Shukun Y, Garcia-Reina G, Lindbland P, Pedersen M (1992) Osmotic adjustment in the cyanobacterium Spirulina platensis: Presence of an a-glucosidase. Plant Physiol Biochem 30:573–578

Mostert ES, Grobbelaar JU (1987) The influence of nitrogen and phosphorus on algal growth and quality in outdoor mass algal cultures. Biomass 13:219–233

Palacios OA, Lopez BR, De-Bashan LE (2022) Microalga growth-promoting bacteria (MGPB): a formal term proposed for beneficial bacteria involved in microalgal–bacterial interactions. Algal Res 61:102585

Pandey JP, Tiwari A, Mishra RM (2010) Evaluation of biomass production of Spirulina maxima on different reported media. J Algal Biomass Util 1(3):70–81

Pelizer LH, Danesi EDG, de Rangel CO, Sassano CE, Carvalho JCM, Sato S, Moraes IO (2003) Influence of inoculum age and concentration in Spirulina platensis cultivation. J Food Eng 56(4):371–375

Pumas P, Pumas C (2016) Cultivation of Arthrospira (Spirulina) platensis using lowcost medium supplemented with Lac wastewater. Chiang Mai J Sci 43:1037–1047

Ragaza JA, Hossain MS, Meiler KA, Velasquez SF, Kumar V (2020) A review on Spirulina: alternative media for cultivation and nutritive value as an aquafeed. Rev Aquac 12(4):2371–2395

Raoof B, Kaushik BD, Prasanna R (2006) Formulation of a low-cost medium for mass production of Spirulina. Biomass Bioenerg 30:537–547

Richmond A (1988) Spirulina. In: Borowitzka MA, Borowitzka LJ (eds) Micro-algal biotechnology. Cambridge University Press, Great Britain, pp 58–121

Rodriguez R, Guerrero MG, Lara C (1994) Mechanism of sodium/nitrate symport in Anacystis nidulans R2. Biochim Biophys Acta 1187:250–254

Selvendran D (2015) Large scale algal biomass (Spirulina) production in India. Algal biorefinery: an integrated approach. Springer, Cham, pp 151–167

Sharoba AM (2014) Nutritional value of spirulina and its use in the preparation of some complementary baby food formulas. J Food Dairy Sci 5:517–538

Soni RA, Sudhakar K, Rana RS (2017) Spirulina-from growth to nutritional product: a review. Trends Food Sci Technol 69:157–171

Sujatha K, Nagarajan P (2014) Effect of salinity on biomass and biochemical constituents of Spirulina platensis (Geitler). Int J Plant Prot 7(1):71–73

Sukumaran P, Nulit R, Halimoon N, Simoh S, Omar H, Ismail A (2018) Formulation of cost-effective medium using urea as a nitrogen source for Arthrospira platensis cultivation under real environment. Annu Res Rev Biol 22(2):1–12

Tedesco MA, Duerr EO (1989) Light, temperature and nitrogen starvation effects on the total lipid and fatty acid content and composition of Spirulina platensis UTEX 1928. J Appl Phycol 1(3):201–209

Thevarajah B, Nishshanka GKSH, Premarate M, Nimarshana PHV, Nagarajan D, Chang JS, Ariyadasa TU (2022) Large-scale production of spirulina-based proteins and c-phycocyanin: a biorefinery approach. Biochem Eng J 185:108541

Tiburcio PC, Galvex FCF, Cruz LJ, Gavino VC (2007) Determination of shelf life of Spirulina platensis (MI2) grown in the Philippines. J Appl Phycol 19:727–731

Tokuşoglu Ö, Üunal MK (2003) Biomass nutrient profiles of three microalgae: Spirulina platensis, Chlorella vulgaris, and Isochrisis galbana. J Food Sci 68(4):1144–1148

UN-SDGs (2019) United Nations sustainable development goals platform. https://sustainabledevelopment.un.org/sdgs Accessed 21 Sept 2022.

Usharani G, Srinivasan G, Sivasakthi S (2014) Analysis of biochemical constituents in Spirulina platensis cultivated using rice mill effluent supplementation. Int J Recent Sci Res 5:2183–2187

Vadiraja BB, Gaikwad NW, Madyastha KM (1998) Hepatoprotective effect of phycocyanin: protection for carbon tetrachloride and R-(+)-pulegone-mediated hepatotoxicty in rats. Biochem Biophys Res Commun 249:428–431

Vieira Costa JA, Cozza KL, Oliveira L, Magagnin G (2001) Different nitrogen sources and growth responses of Spirulina platensis in microenvironments. World J Microbiol Biotechnol 17:439–442

Vonshak A (1997) Mass Culture of spirulina outdoors-the earthrise farms experience. Spirulina Platensis Arthrospira. CRC Press, pp 149–176

Vonshak A (1997b) Spirulina Platensis Arthrospira: physiology, cell biology and biotechnology, 1st Edn. CRC Press. p 233

Vonshak A, Richmond A (1988) Mass production of blue-green alga Spirulina : an overview. Biomass 15:233–247

Yucetepe A, Saroglu O, Bildik F, Ozcelik B, Daskaya-Dikmen C (2018) Optimisation of ultrasound-assisted extraction of protein from Spirulina platensis using RSM. Czech J Food Sci 36(1):98–108

Zapata D, Arroyave C, Cardona L, Aristizábal A, Poschenrieder C, Llugany M (2021) Phytohormone production and morphology of Spirulina platensis grown in dairy wastewaters. Algal Res 59:102469

Zhang L, Chen L, Wang J, Chen Y, Gao X, Zhang Z, Liu T (2015) Attached cultivation for improving the biomass productivity of Spirulina platensis. Biores Technol 181:136–142

Acknowledgements

This work was part of the research project entitled “Production of Spirulina Biomass: Refinement of Grow-out Production Technology and Piloting in Northern Mindanao” funded by the local grants-in-aid program of the Department of Science and Technology-Regional Office X. Moreover, the support of the Cagayan de Oro Chamber of Commerce and Industry Foundation, Inc., through its OROBEST Innovation Program, is highly appreciated. Furthermore, the authors sincerely thank the Reviewers for taking the time and effort necessary to review the manuscript. We sincerely appreciate all valuable comments and suggestions, which helped us to improve the quality of the manuscript.

Author information

Authors and Affiliations

Contributions

KINU made substantial contributions to the concept and design of all the experiments; the acquisition, analysis, and interpretation of the data; the writing of the final manuscript; and the direction of the research. GDG, JMLP, and FCB made substantial contributions to the concept and design of all the experiments as well as to the data acquisition and analysis. RDG contributed substantially to the concept, design, and finalization of the manuscript. All the authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Uba, K.I.N., Gaid, G.D., Perales, J.M.L. et al. From Laboratory to Production: Innovating the Small-scale Mass Production of Spirulina (Arthrospira platensis) with an Alternative Culture Medium and Refined Culture Conditions. Agric Res (2024). https://doi.org/10.1007/s40003-024-00709-7

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40003-024-00709-7