Abstract

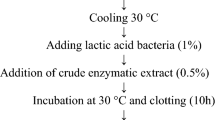

The aim of this study was to investigate the effect of camel chymosin and different types of starter cultures on the chemical, textural, proteolytic and lipolytic characteristics of semi-hard white cheese prepared from camel milk during ripening. Two treatments of chesses consisting of thermophilic starter culture camel cheese (CC-TC) containing Streptococcus salivarius subsp. thermophilus and Lactobacillus delbrueckii subsp. bulgaricus and the mixture of thermophilic/mesophilic yogurt starter culture camel cheese (CC-YC) containing S. salivarius subsp. thermophilus, Lactobacillus delbrueckii subsp. bulgaricus, Lacticaseibacillus casei subsp. casei and Levilactobacillus brevis were manufactured. Results show that camel cheese which was produced with YC as a starter culture had more yield in comparison with TC. The chemical changes were significantly higher in CC-YC (P < 0.05). The hydrolysis of αs1-casein, β-casein and formation of their degradation products was relatively high in CC-YC. The total FFAs were significantly (P < 0.05) changed during 60 days of ripening and between CC-TC and CC-YC. The main substrate of lipolytic enzymes from both CC-TC and CC-YC was short-chain fatty acids containing butyric, caproic, capric, lauric, myristic, myristoleic, palmitic in camel cheeses which was decreased during ripening. Whereas CC-TC showed maximum hardness, adhesiveness, stringiness. However, CC-YC showed maximum resilience, cohesiveness, springiness, gumminess and chewiness. Therefore, the use of thermophilic/mesophilic yogurt culture is recommended for the production of good quality semi-hard white camel cheese, considering the chemical and textural characteristics of the cheese.

Similar content being viewed by others

References

Al-Zoreky NS, Almathen FS (2021) Using recombinant camel chymosin to make white soft cheese from camel milk. Food Chem 337:127994

Al Kanhal HA (2010) Compositional, technological and nutritional aspects of dromedary camel milk. Int Dairy J 20(12):811–821

Atasoy AF, Türkoğlu H (2009) Lipolysis in Urfa cheese produced from raw and pasteurized goats’ and cows’ milk with mesophilic or thermophilic cultures during ripening. Food Chem 115(1):71–78

Awad S, Hassan A, Muthukumarappan K (2005) Application of exopolysaccharide-producing cultures in reduced-fat Cheddar cheese: texture and melting properties. J Dairy Sci 88(12):4204–4213

Baig D, Sabikhi L, Khetra Y, Kumar D (2022) Effect of casein to fat ratio of camel milk on solids losses in cheese whey and their recovery in camel milk cheese. Int Dairy J 124:105185

Bekele B, Hansen EB, Eshetu M, Ipsen R, Hailu Y (2019) Effect of starter cultures on properties of soft white cheese made from camel (Camelus dromedarius) milk. J Dairy Sci 102(2):1108–1115

Benkerroum N, Dehhaoui M, El Fayq A, Tlaiha R (2011) The effect of concentration of chymosin on the yield and sensory properties of camel cheese and on its microbiological quality. Int J Dairy Technol 64(2):232–239

Bertolino M, Dolci P, Giordano M, Rolle L, Zeppa G (2011) Evolution of chemico-physical characteristics during manufacture and ripening of Castelmagno PDO cheese in wintertime. Food Chem 129(3):1001–1011

Bontinis TG, Mallatou H, Pappa E, Massouras T, Alichanidis E (2012) Study of proteolysis, lipolysis and volatile profile of a traditional Greek goat cheese (Xinotyri) during ripening. Small Rumin Res 105(1):193–201

Cakir Y, Cakmakci S, Hayaloglu AA (2016) The effect of addition of black cumin (Nigella sativa L.) and ripening period on proteolysis, sensory properties and volatile profiles of Erzincan Tulum (Şavak) cheese made from raw Akkaraman sheep’s milk. Small Rumin Res 134:65–73

Cepoglu F, Guler-Akin MB (2013) Effects of coagulating enzyme types (commercial calf rennet, Aspergillus niger var. awamori as recombinant chymosin and Rhizomucor miehei as microbial rennet) on the chemical and sensory characteristics of white pickled cheese. Afr J Biotechnol 12(37):5588–5594

Costabel LM, Bergamini C, Vaudagna SR, Cuatrin AL, Audero G, Hynes E (2016) Effect of high-pressure treatment on hard cheese proteolysis. J Dairy Sci 99(6):4220–4232

Diezhandino I, Fernández D, González L, McSweeney P, Fresno J (2015) Microbiological, physico-chemical and proteolytic changes in a Spanish blue cheese during ripening (Valdeón cheese). Food Chem 168:134–141

Diezhandino I, Fernández D, Sacristán N, Combarros-Fuertes P, Prieto B, Fresno J (2016) Rheological, textural, colour and sensory characteristics of a Spanish blue cheese (Valdeón cheese). LWT Food Sci Technol 65:1118–1125

Farahani G, Ezzatpanah H, Abbasi S (2014) Characterization of Siahmazgi cheese, an Iranian ewe’s milk variety: assessment of physico-chemical, textural and rheological specifications during ripening. LWT Food Sci Technol 58(2):335–342

Fox PF, Guinee TP, Cogan TM, McSweeney PL (2016) Fundamentals of cheese science, 2nd edn. Springer, New York

Georgala A, Moschopoulou E, Aktypis A, Massouras T, Zoidou E, Kandarakis I, Anifantakis E (2005) Evolution of lipolysis during the ripening of traditional Feta cheese. Food Chem 93(1):73–80

Giannoglou M, Karra Z, Platakou E, Katsaros G, Moatsou G, Taoukis P (2016) Effect of high pressure treatment applied on starter culture or on semi-ripened cheese in the quality and ripening of cheese in brine. Innov Food Sci Emerg Technol 38:312–320

Gonzalez MM, Vivar-Quintana A, Revilla I, Salvador-Esteban J (2020) The determination of fatty acids in cheeses of variable composition (cow, ewe’s, and goat) by means of near infrared spectroscopy. Microchem J 156:104854

Guidone A, Braghieri A, Cioffi S, Claps S, Genovese F, Morone G, Napolitano F, Parente E (2015) Effect of adjuncts on microbiological and chemical properties of Scamorza cheese. J Dairy Sci 98(3):1467–1478

Gunasekaran S, Ak MM (2002) Cheese rheology and texture. CRC Press, Florida

Hailu Y, Hansen EB, Seifu E, Eshetu M, Ipsen R (2016) Factors influencing the gelation and rennetability of camel milk using camel chymosin. Int Dairy J 60:62–69

Hailu Y, Seifu E, Yilma Z (2014) Physicochemical properties and consumer acceptability of soft unripened cheese made from camel milk using crude extract of ginger (Zingiber officinale) as coagulant. Afr J Food Sci 8(2):87–91

Ho TM, Zou Z, Bansal N (2022) Camel milk: a review of its nutritional value, heat stability, and potential food products. Food Res Int 153:110870

ISO 5943 (1988) Cheese and processed cheese products determination of chloride content: potentiometric titration method. International Organization for Standardization, Geneva

ISO14156 (2001) Milk and milk product-extraction method for lipid and insoluble compounds. International Organization for Standardization, Geneva

ISO 15884 (2002) Preparation of fatty acid methyl esters. International Organization for Standardization, Geneva

ISO5537 (2004) Dried milk: determination of moisture content (Reference method). International Organization for Standardization, Geneva

ISO488 (2008) Milk: determination of fat content: Gerber butyrometers. International Organization for Standardization, Geneva

ISO8968-1 (2014) Milk and milk products: determination of nitrogen content-Part 1: Kjeldahl principle and crude protein calculation. International Organization for Standardization, Geneva

Kamal M, Foukani M, Karoui R (2017) Rheological and physical properties of camel and cow milk gels enriched with phosphate and calcium during acid-induced gelation. J Food Sci Technol 54(2):439–446

Kirmaci H, Hayaloglu A, Özer H, Atasoy A, Türkoğlu H (2014) Evolution of proteolysis in Urfa cheese made from ewe’s milk by wild type starter culture systems. Small Rumin Res 119(1):120–129

Konuspayeva G, Camier B, Gaucheron F, Faye B (2014) Some parameters to process camel milk into cheese. Emir J Food Agric 26(4):354

Li B, Waldron DS, Drake M, Lyne J, Kelly AL, McSweeney PL (2022) Suitability of a novel camel (Camelus dromedarius) chymosin as a coagulant for Cheddar cheese manufacture. Int Dairy J 129:105346

Masotti F, Cattaneo S, Stuknytė M, Battelli G, Vallone L, De Noni I (2017) Composition, proteolysis, and volatile profile of Strachitunt cheese. J Dairy Sci 100(3):1679–1687

Mbye M, Ayyash M, Abu-Jdayil B, Kamal-Eldin A (2022) The texture of camel milk cheese: effects of milk composition, coagulants, and processing conditions. Front Nutr 9:868320

Miloradovic Z, Kljajevic N, Miocinovic J, Tomic N, Smiljanic J, Macej O (2017) High heat treatment of goat cheese milk. The effect on yield, composition, proteolysis, texture and sensory quality of cheese during ripening. Int Dairy J 68:1–8

Moynihan A, Govindasamy-Lucey S, Jaeggi J, Johnson M, Lucey J, McSweeney P (2014) Effect of camel chymosin on the texture, functionality, and sensory properties of low-moisture, part-skim Mozzarella cheese. J Dairy Sci 97(1):85–96

Muthukumaran MS, Mudgil P, Baba WN, Ayoub MA, Maqsood S (2022) A comprehensive review on health benefits, nutritional composition and processed products of camel milk. Food Rev Int. https://doi.org/10.1080/87559129.2021.2008953

Orundu S, Tarakci Z (2021) Effects of different starter culture applications pre-and post-scalding on the biochemical and sensory properties of pasta filata type cheeses. LWT 136:110288

Ozturkoglu-Budak S, Akal HC, Bereli N, Cimen D, Akgonullu S (2021) Use of antimicrobial proteins of donkey milk as preservative agents in Kashar cheese production. Int Dairy J 120:105090

Pappa EC, Kondyli E, Bosnea L, Malamou E, Vlachou AM (2022) Chemical, microbiological, sensory, and rheological properties of fresh goat milk cheese made by different starter cultures during storage. J Food Process Eng 45(7):e13788

Paszczyk B, Łuczyńska J (2020) The comparison of fatty acid composition and lipid quality indices in hard cow, sheep, and goat cheeses. Foods 9(11):1667

Qadeer Z, Huma N, Sameen A, Iqbal T (2015) Camel milk cheese: optimization of processing conditions. J Camelid Sci 8:18–25

Renes E, Gómez-Cortés P, de La Fuente M, Linares DM, Tornadijo ME, Fresno JM (2019) CLA-producing adjunct cultures improve the nutritional value of sheep cheese fat. Food Res Int 116:819–826

Salami M, Sadeghian Motahar SF, Ariaeenejad S, Sheykh Abdollahzadeh Mamaghani A, Kavousi K, Moosavi-Movahedi AA, Hosseini Salekdeh G (2022) The novel homologue of the human α-glucosidase inhibited by the non-germinated and germinated quinoa protein hydrolysates after in vitro gastrointestinal digestion. J Food Biochem 46(1):e14030

Sert D, Akin N, Aktumsek A (2014) Lipolysis in Tulum cheese produced from raw and pasteurized goats’ milk during ripening. Small Rumin Res 121(2):351–360

Shuiep E, Jäger S, El Zubeir I, Yousif I, Erhardt G (2016) Isolation and characterization of three camel (Camelus dromedarius) milk casein fractions. J Vet Med Anim Prod 6(1):43–50

Singh R, Mal G, Kumar D, Patil N, Pathak K (2017) Camel milk: an important natural adjuvant. J Agric Res 6(4):327–340

Soltani M, Guzeler N, Hayaloglu AA (2015) The influence of salt concentration on the chemical, ripening and sensory characteristics of Iranian white cheese manufactured by UF-Treated milk. J Dairy Res 82(3):365–374

Sulejmani E, Hayaloglu AA (2020) Influence of starter culture on nitrogen fraction and volatile compounds in Beaten cow’s milk cheese. J Food Process Preserv 44(9):e14689

Tomar O (2019) The effects of probiotic cultures on the organic acid content, texture profile and sensory attributes of Tulum cheese. Int J Dairy Technol 72(2):218–228

Tunick MH (2010) Small-strain dynamic rheology of food protein networks. J Agric Food Chem 59(5):1481–1486

Zaravela A, Kontakos S, Badeka A, Kontominas M (2021) Effect of adjunct starter culture on the quality of reduced fat, white, brined goat cheese: part I. Assessment of chemical composition, proteolysis, lipolysis, texture and sensory attributes. Eur Food Res Technol 247(9):2211–2225

Zhao DB, Bai YH, Niu YW (2015) Composition and characteristics of Chinese Bactrian camel milk. Small Rumin Res 127:58–67

Zonoubi R, Goli M (2021) The effect of complete replacing sodium with potassium, calcium, and magnesium brine on sodium-free ultrafiltration Feta cheese at the end of the 60-day ripening period: physicochemical, proteolysis–lipolysis indices, microbial, colorimetric, and sensory evaluation. Food Sci Nutr 9(2):866–874

Acknowledgments

The authors would like to thank the department of food science and nutrition, Tehran medical university, Islamic Azad University for cooperation of this research.

Author information

Authors and Affiliations

Contributions

SA contributed to conceptualization, methodology, software, formal analysis, writing and original draft preparation; YR contributed to methodology, data analysis, review and editing the manuscript, resources, validation; MS contributed to methodology, data analysis, resources, validation. All authors read and agreed to the published version of the manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflicts of interest.

Ethical approval

The authors declare compliance with all ethics requirements.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Abbaschian, S., Ramezan, Y. & Salami, M. Chemical, Textural and Ripening Characteristics of Semi-hard White Cheese Prepared from Camel Milk Using Camel Chymosin and Different Starter Cultures. Agric Res 12, 325–338 (2023). https://doi.org/10.1007/s40003-023-00654-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40003-023-00654-x