Abstract

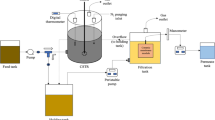

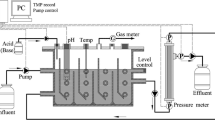

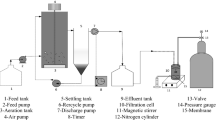

This work describes the fouling of industrial waste sugarcane bagasse ash ceramic membrane (pore size ~ 8.6 µm; water permeability 27.2 × 103 L/m2 h bar) in wastewater treatment in anaerobic membrane bioreactor (AnMBR). AnMBR system was operated in sequential batch reactor (SBR) mode at 18 h hydraulic retention time for 31 days. For influent concentration of 171 ± 12 mg COD/L, average chemical oxygen demand (COD) removal was high (~ 94%). Biomass activity of anaerobic sludge improved from 0.15 (day 1) to 0.35 mg CODremoved/mg MLVSS.d (day 31). Operating flux was maintained at 17.8 ± 1.4 L/m2 h and the transmembrane pressure reached up to 170 mbar on day 31, increasing at a rate of 15.7 mbar/d. Specific bound extracellular polymeric substance (EPS) concentration was much higher in surface deposits (356 mg EPS/g MLVSS) than in the reactor sludge suspension (32.3 ± 14.4 mg EPS/g MLVSS). Though SBR is a good alternative configuration to reduce membrane exposure to sludge and hence control the fouling rate, formation of cake layer (due to deposition of sludge fines on membrane surface) still cannot be prevented. Calculation of total filtration resistance (Rt) showed the resistance of the caked surface deposits, Rc (2.19 × 1012 m−1) to be dominant at 83% of Rt. Of the two fouling control strategies tested viz. filtration-relaxation (4 min–1 min) and permeate backflushing (up to 3 times operating flux), backflushing was more effective. These findings indicate the potential of these alternative membranes in wastewater treatment application; at the same time, further investigations are required to minimize membrane fouling.

Similar content being viewed by others

Availability of data and materials

Not applicable.

References

Abdullayev A, Bekheet MF, Hanaor DA, Gurlo A (2019) Materials and applications for low-cost ceramic membranes. Membranes 9(9):105. https://doi.org/10.3390/membranes9090105

Ahmad B, Dilshad MR, Haider B, Anwar MM, Ali H, Gilani SMA, Ahmad HB, Farooq M (2021) Synthesis of novel fly ash based geo-polymeric membranes for the treatment of textile waste water. Int J Environ Sci Technol. https://doi.org/10.1007/s13762-021-03527-4

Arumugham T, Kaleekkal NJ, Gopal S, Nambikkattu J, Rambabu K, Aboulella AM, Wickramasinghe SR, Banat F (2021) Recent developments in porous ceramic membranes for wastewater treatment and desalination: a review. J Environ Manag 293:112925. https://doi.org/10.1016/j.jenvman.2021.112925

Aslam M, Yang P, Lee PH, Kim J (2018) Novel staged anaerobic fluidized bed ceramic membrane bioreactor: energy reduction, fouling control and microbial characterization. J Membr Sci 553:200–208. https://doi.org/10.1016/j.memsci.2018.02.038

Balakrishnan M, Batra VS, Dikshit PK, Yadav S (2020) Silica MBRs: design, configuration, and performance. Current trends and future developments on (bio-) membranes. Elsevier, pp 31–91. https://doi.org/10.1016/B978-0-12-816822-6.00002-1

Balcıoğlu G, Vergili I, Gönder ZB, Yilmaz G, Bacaksiz AM, Kaya Y (2022) Effect of powdered activated carbon addition on membrane performance and fouling in anaerobic membrane bioreactor. Int J Environ Sci Technol. https://doi.org/10.1007/s13762-022-04203-x

Basu S, Singh SK, Tewari PK, Batra VS, Balakrishnan M (2014) Treatment of nitrate-rich water in a baffled membrane bioreactor (BMBR) employing waste derived materials. J Environ Manag 146:16–21. https://doi.org/10.1016/j.jenvman.2014.07.022

Chen R, Nie Y, Hu Y, Miao R, Utashiro T, Li Q, Xu M, Li YY (2017) Fouling behaviour of soluble microbial products and extracellular polymeric substances in a submerged anaerobic membrane bioreactor treating low-strength wastewater at room temperature. J Membr Sci 531:1–9. https://doi.org/10.1016/j.memsci.2017.02.046

Chen C, Sun M, Liu Z, Zhang J, Xiao K, Zhang X, Song G, Chang J, Liu G, Wang H, Huang X (2021) Robustness of granular activated carbon-synergized anaerobic membrane bioreactor for pilot-scale application over a wide seasonal temperature change. Water Res 189:116552. https://doi.org/10.1016/j.watres.2020.116552

Chen C, Sun M, Chang J, Liu Z, Zhu X, Xiao K, Song G, Wang H, Liu G, Huang X (2022) Unravelling temperature-dependent fouling mechanism in a pilot-scale anaerobic membrane bioreactor via statistical modelling. J Membr Sci 644:120145. https://doi.org/10.1016/j.memsci.2021.120145

Chu LB, Yang FL, Zhang XW (2005) Anaerobic treatment of domestic wastewater in a membrane-coupled expended granular sludge bed (EGSB) reactor under moderate to low temperature. Process Biochem 40(3–4):1063–1070. https://doi.org/10.1016/j.procbio.2004.03.010

De Vela RJ (2021) A review of the factors affecting the performance of anaerobic membrane bioreactor and strategies to control membrane fouling. Rev Environ Sci Biotechnol 20(3):607–644. https://doi.org/10.1007/s11157-021-09580-2

Delikanli NE, Harman BI, Yigit NO, Sardohan Koseoglu T, Kitis M, Koseoglu H (2022) Separation of Cu2+ from membrane concentrate by SiO2/3-aminopropyltriethoxysilane-coated ceramic membrane. Int J Environ Sci Technol 19(1):379–390. https://doi.org/10.1007/s13762-021-03157-w

Dhiman S, Balakrishnan M, Naddeo V, Ahsan N (2023) Performance of anaerobic membrane bioreactor (AnMBR) with sugarcane bagasse ash-based ceramic membrane treating simulated low-strength municipal wastewater: effect of operation conditions. Water Air Soil Pollut 234(3):141. https://doi.org/10.1007/s11270-023-06173-3

Dong Y, Chen S, Zhang X, Yang J, Liu X, Meng G (2006) Fabrication and characterization of low cost tubular mineral-based ceramic membranes for micro-filtration from natural zeolite. J Membr Sci 281(1–2):592–599. https://doi.org/10.1016/j.memsci.2006.04.029

Dubois M, Gilles KA, Hamilton JK, Rebers PT, Smith F (1956) Colorimetric method for determination of sugars and related substances. Anal Chem 28(3):350–356. https://doi.org/10.1021/ac60111a017

Fang J, Qin G, Wei W, Zhao X (2011) Preparation and characterization of tubular supported ceramic microfiltration membranes from fly ash. Sep Purif Technol 80(3):585–591. https://doi.org/10.1016/j.seppur.2011.06.014

Giménez JB, Robles A, Carretero L, Durán F, Ruano MV, Gatti MN, Ribes J, Ferrer J, Seco A (2011) Experimental study of the anaerobic urban wastewater treatment in a submerged hollow-fibre membrane bioreactor at pilot scale. Bioresour Technol 102(19):8799–8806. https://doi.org/10.1016/j.biortech.2011.07.014

Goswami KP, Pakshirajan K, Pugazhenthi G (2022) Process intensification through waste fly ash conversion and application as ceramic membranes: a review. Sci Total Environ 808:151968. https://doi.org/10.1016/j.scitotenv.2021.151968

Hasan MM, Shafiquzzaman M, Azam MS, Nakajima J (2011) Application of a simple ceramic filter to membrane bioreactor. Desalination 276(1–3):272–277. https://doi.org/10.1016/j.desal.2011.03.062

Hatree EF (1972) Determination of protein: a modification of the Lowry method that gives a linear photometric response. Anal Biochem 48:422–427. https://doi.org/10.1016/0003-2697(72)90094-2

Ho JH, Khanal SK, Sung S (2007) Anaerobic membrane bioreactor for treatment of synthetic municipal wastewater at ambient temperature. Water Sci Technol 55(7):79–86. https://doi.org/10.2166/wst.2007.130

Hofs B, Ogier J, Vries D, Beerendonk EF, Cornelissen ER (2011) Comparison of ceramic and polymeric membrane permeability and fouling using surface water. Sep Purif Technol 79(3):365–374. https://doi.org/10.1016/j.seppur.2011.03.025

Huang Z, Ong SL, Ng HY (2011) Submerged anaerobic membrane bioreactor for low-strength wastewater treatment: effect of HRT and SRT on treatment performance and membrane fouling. Water Res 45(2):705–713. https://doi.org/10.1016/j.watres.2010.08.035

Hubadillah SK, Othman MHD, Tai ZS, Jamalludin MR, Yusuf NK, Ahmad A, Rahman MA, Jaafar J, Kadir SHSA, Harun Z (2020) Novel hydroxyapatite-based bio-ceramic hollow fiber membrane derived from waste cow bone for textile wastewater treatment. Chem Eng J 379:122396. https://doi.org/10.1016/j.cej.2019.122396

Hubadillah SK, Jamalludin MR, Othman MHD, Iwamoto Y (2022) Recent progress on low-cost ceramic membrane for water and wastewater treatment. Ceram Int. https://doi.org/10.1016/j.ceramint.2022.05.255

Jamalludin MR, Harun Z, Othman MHD, Hubadillah SK, Yunos MZ, Ismail AF (2018) Morphology and property study of green ceramic hollow fiber membrane derived from waste sugarcane bagasse ash (WSBA). Ceram Int 44(15):18450–18461. https://doi.org/10.1016/j.ceramint.2018.07.063

Jang Y, Kim HS, Ham SY, Park JH, Park HD (2021) Investigation of critical sludge characteristics for membrane fouling in a submerged membrane bioreactor: Role of soluble microbial products and extracted extracellular polymeric substances. Chemosphere 271:129879. https://doi.org/10.1016/j.chemosphere.2021.129879

Jeong Y, Cho K, Kwon EE, Tsang YF, Rinklebe J, Park C (2017a) Evaluating the feasibility of pyrophyllite-based ceramic membranes for treating domestic wastewater in anaerobic ceramic membrane bioreactors. Chem Eng J 328:567–573. https://doi.org/10.1016/j.cej.2017.07.080

Jeong Y, Lee S, Hong S, Park C (2017b) Preparation, characterization and application of low-cost pyrophyllite-alumina composite ceramic membranes for treating low-strength domestic wastewater. J Membr Sci 536:108–115. https://doi.org/10.1016/j.memsci.2017.04.068

Ji J, Sakuma S, Ni J, Chen Y, Hu Y, Ohtsu A, Chen R, Cheng H, Qin Y, Hojo T, Kubota K (2020) Application of two anaerobic membrane bioreactors with different pore size membranes for municipal wastewater treatment. Sci Total Environ 745:140903. https://doi.org/10.1016/j.scitotenv.2020.140903

Kong Z, Li L, Wu J, Wang T, Rong C, Luo Z, Pan Y, Li D, Li Y, Huang Y, Li YY (2021) Evaluation of bio-energy recovery from the anaerobic treatment of municipal wastewater by a pilot-scale submerged anaerobic membrane bioreactor (AnMBR) at ambient temperature. Bioresour Technol 339:125551. https://doi.org/10.1016/j.biortech.2021.125551

Lawal NS, Ogedengbe K, Ojo O, Odufowokan AA (2020) Assessment of a submerged membrane bioreactor with composite ceramic filters for cassava wastewater treatment. Res Agric Eng 66(2):72–79. https://doi.org/10.17221/109/2018-RAE

Li XY, Yang SF (2007) Influence of loosely bound extracellular polymeric substances (EPS) on the flocculation, sedimentation and dewaterability of activated sludge. Water Res 41(5):1022–1030. https://doi.org/10.1016/j.watres.2006.06.037

Lin H, Chen J, Wang F, Ding L, Hong H (2011) Feasibility evaluation of submerged anaerobic membrane bioreactor for municipal secondary wastewater treatment. Desalination 280(1–3):120–126. https://doi.org/10.1016/j.desal.2011.06.058

Liu Y, Liu H, Cui L, Zhang K (2012) The ratio of food-to-microorganism (F/M) on membrane fouling of anaerobic membrane bioreactors treating low-strength wastewater. Desalination 297:97–103. https://doi.org/10.1016/j.desal.2012.04.026

Liu Y, Zhang X, Ngo HH, Guo W, Wen H, Deng L, Li Y, Guo J (2018) Specific approach for membrane fouling control and better treatment performance of an anaerobic submerged membrane bioreactor. Bioresour Technol 268:658–664. https://doi.org/10.1016/j.biortech.2018.08.043

Liu M, Zhu Z, Zhang Z, Chu Y, Yuan B, Wei Z (2020) Development of highly porous mullite whisker ceramic membranes for oil-in-water separation and resource utilization of coal gangue. Sep Purif Technol 237:116483. https://doi.org/10.1016/j.seppur.2019.116483

Liu X, Liu J, Deng D, Li R, Guo C, Ma J, Chen M (2021) Investigation of extracellular polymeric substances (EPS) in four types of sludge: factors influencing EPS properties and sludge granulation. J Water Process Eng 40:101924. https://doi.org/10.1016/j.jwpe.2021.101924

Mouratib R, Achiou B, El KM, Younssi SA, Tahiri S (2020) Low-cost ceramic membrane made from alumina-and silica-rich water treatment sludge and its application to wastewater filtration. J Eur Ceram Soc 40(15):5942–5950. https://doi.org/10.1016/j.jeurceramsoc.2020.07.050

Neto JDSA, de França MJS, de Amorim Junior NS, Ribeiro DV (2021) Effects of adding sugarcane bagasse ash on the properties and durability of concrete. Constr Build Mater 266:120959. https://doi.org/10.1016/j.conbuildmat.2020.120959

Nilusha RT, Yu D, Zhang J, Wei Y (2020) Effects of solids retention time on the anaerobic membrane bioreactor with yttria-based ceramic membrane treating domestic wastewater at ambient temperature. Membranes 10(9):196. https://doi.org/10.3390/membranes10090196

Qin W, Peng C, Wu J (2017) A sacrificial-interlayer technique for single-step coating preparation of highly permeable alumina membrane. Ceram Int 43(1):901–904. https://doi.org/10.1016/j.ceramint.2016.09.206

Qiu M, Fan Y, Xu N (2010) Preparation of supported zirconia ultrafiltration membranes with the aid of polymeric additives. J Membr Sci 348(1–2):252–259. https://doi.org/10.1016/j.memsci.2009.11.009

Rasouli Y, Abbasi M, Hashemifard SA (2019) A new combination of microfiltration, powdered activated carbon and coagulation for treatment of oily wastewater. Int J Environ Sci Technol 16:5595–5610. https://doi.org/10.1007/s13762-018-1906-5

Robles A, Ruano MV, Ribes J, Ferrer J (2013) Performance of industrial scale hollow-fibre membranes in a submerged anaerobic MBR (HF-SAnMBR) system at mesophilic and psychrophilic conditions. Sep Purif Technol 104:290–296. https://doi.org/10.1016/j.seppur.2012.12.004

Shafiquzzaman M, Alharbi SK, Haider H, AlSaleem SS, Ghumman AR (2020) Development and evaluation of treatment options for recycling ablution greywater. Int J Environ Sci Technol 17:1225–1238. https://doi.org/10.1007/s13762-019-02537-7

Shim JK, Yoo IK, Lee YM (2002) Design and operation considerations for wastewater treatment using a flat submerged membrane bioreactor. Process Biochem 38(2):279–285. https://doi.org/10.1016/S0032-9592(02)00077-8

Smith AL, Skerlos SJ, Raskin L (2013) Psychrophilic anaerobic membrane bioreactor treatment of domestic wastewater. Water Res 47(4):655–1665. https://doi.org/10.1016/j.watres.2012.12.028

Tomar SK, Chakraborty S (2018) Effect of air flow rate on development of aerobic granules, biomass activity and nitrification efficiency for treating phenol, thiocyanate and ammonium. J Environ Manag 219:178–188. https://doi.org/10.1016/j.jenvman.2018.04.111

Umamaheswaran K, Batra VS (2008) Physico-chemical characterisation of Indian biomass ashes. Fuel 87(6):628–638. https://doi.org/10.1016/j.fuel.2007.05.045

Wang Z, Xu Z, Qiu D, Chu Y, Tang Y (2021) Beneficial utilization of Al/Si/O-rich solid wastes for environment-oriented ceramic membranes. J Hazard Mater 401:123427. https://doi.org/10.1016/j.jhazmat.2020.123427

Wu SC, Lee CM (2011) Correlation between fouling propensity of soluble extracellular polymeric substances and sludge metabolic activity altered by different starvation conditions. Bioresour Technol 102(9):5375–5380. https://doi.org/10.1016/j.biortech.2010.11.093

Xiong Y, Harb M, Hong PY (2016) Characterization of biofoulants illustrates different membrane fouling mechanisms for aerobic and anaerobic membrane bioreactors. Sep Purif Technol 157:192–202. https://doi.org/10.1016/j.seppur.2015.11.024

Yin X, Guan K, Gao P, Peng C, Wu J (2018) A preparation method for the highly permeable ceramic microfiltration membrane–precursor film firing method. RSC Adv 8(6):2906–2914. https://doi.org/10.1039/C7RA12314K

Yue X, Koh YKK, Ng HY (2015) Effects of dissolved organic matters (DOMs) on membrane fouling in anaerobic ceramic membrane bioreactors (AnCMBRs) treating domestic wastewater. Water Res 86:96–107. https://doi.org/10.1016/j.watres.2015.07.038

Zhang HM, Xiao JN, Cheng YJ, Liu LF, Zhang XW, Yang FL (2006) Comparison between a sequencing batch membrane bioreactor and a conventional membrane bioreactor. Process Biochem 41(1):87–95. https://doi.org/10.1016/j.procbio.2005.03.072

Zhao C, Xu X, Chen J, Wang G, Yang F (2014) Highly effective antifouling performance of PVDF/graphene oxide composite membrane in membrane bioreactor (MBR) system. Desalination 340:59–66. https://doi.org/10.1016/j.desal.2014.02.022

Zielińska M, Bułkowska K, Cydzik-Kwiatkowska A, Bernat K, Wojnowska-Baryła I (2016) Removal of bisphenol A (BPA) from biologically treated wastewater by microfiltration and nanofiltration. Int J Environ Sci Technol 13:2239–2248. https://doi.org/10.1007/s13762-016-1056-6

Zou D, Qiu M, Chen X, Drioli E, Fan Y (2019) One step co-sintering process for low-cost fly ash based ceramic microfiltration membrane in oil-in-water emulsion treatment. Sep Purif Technol 210:511–520. https://doi.org/10.1016/j.seppur.2018.08.040

Zuriaga E, Pastor I, Hernández B, Basiero L, Lorente-Ayza MM, Bordes MC, Sanchez E, Abellán M (2017) Low-cost ceramic membranes manufacture for MBR: comparison of pilot and industrial scale. In: Frontiers international conference on wastewater treatment and modelling. Springer, Cham, pp 193–196. https://doi.org/10.1007/978-3-319-58421-8_30

Acknowledgements

The authors are thankful to TERI for the research facility to conduct this work. The membrane mercury porosimetry analysis done by R. K. Singh, TERI is also greatly appreciated. The constructive comments provided by the anonymous reviewer that helped us to improve the manuscript are much appreciated.

Funding

S. Dhiman is grateful to University Grants Commission for Junior and Senior Research Fellowship (UGC Ref. No. 3781/NET-DEC2018).

Author information

Authors and Affiliations

Contributions

SD: Conducting AnMBR experiments, data analysis, writing. SY: Membrane preparation and characterization, data analysis. MB: Supervision, review and editing. NA: Supervision.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflict of interests.

Ethical approval

No applicable.

Consent to participate

Not applicable.

Consent to publication

All co-authors agree to the publishing of this work in International Journal of Environmental Science and Technology.

Additional information

Editorial responsibility: Samareh Mirkia.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Dhiman, S., Yadav, S., Balakrishnan, M. et al. Fouling behaviour of industrial waste-based ceramic membrane in anaerobic membrane bioreactor treating low strength wastewater. Int. J. Environ. Sci. Technol. 21, 1369–1378 (2024). https://doi.org/10.1007/s13762-023-05070-w

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13762-023-05070-w