Abstract

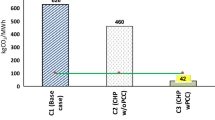

This paper studies the technical–economic performance of a gas-fired power plant with simulation of a carbon capture unit in an oil refinery. In research method, at first, the current condition of a live power plant is analyzed with the help of mathematical relations and software, and in second stage, a carbon capture unit is simulated by post-combustion method. In order to reduce the utility consumption, an attempt was made to use the exhaust steam of the deaerator as the required steam. The unit pressure profile was changed and with the removal of a pump and the initial investment and finally the operating cost of the unit were reduced. The Carbon Capture unit reduces the amount of Carbon dioxide released from 138.06 to 1.51 Million tons/year and reduces the efficiency from 76.282 to 60.480% due to the electricity consumption in pumps and air coolers. Due to the presence of heat recovery steam generators and the maximum use of the heat from the gas turbine exhaust gas, it is practically not possible to reuse a part of this flow, and only by using the excess steam produced by the power plant (injected into the atmosphere) as the heat source of the Re-boiler, the regenerator can increase the overall efficiency of the power plant. Using additional Deaerator steam (injection into the atmosphere), the efficiency of the power plant can be increased from 60.480 to 71.639%.

Similar content being viewed by others

Notes

Carbon dioxide.

Parts per million.

Monoethanolamine.

Diethanolamine.

Methyl diethanolamine.

Diglycolamine.

Carbon capture and storage.

Megawatt.

Heat Recovery Steam Generators.

Million tons/year.

References

Abd AA, Samah ZN (2020) Comparison study of activators performance for MDEA solution of acid gases capturing from natural gas: simulation-based on a real plant. Environ Technol Innov 17:100562

Alhamed YA, Edris GM, GadelHak YM (2014) Performance evaluation of a bubble column photobioreactor for carbon dioxide sequestration by Chlorella vulgaris. Arab J Sci Eng 39(12):8453–8463. https://doi.org/10.1007/s13369-014-1390-2

Boycheva S, Marinov I, Zgureva-Filipova D (2021) Studies on the CO2 capture by coal fly ash zeolites: process design and simulation. Energies 14(24):8279. https://doi.org/10.3390/en14248279

Dash SK et al (2015) Post-combustion CO2 capture with sulfolane based activated alkanolamine solvent. Comput Aid Chem Eng 37:521–526

Desport L, Selosse S (2022) An overview of CO2 capture and utilization in energy models. Resour Conserv Recycl 180:106150. https://doi.org/10.1016/j.resconrec.2021.106150

Eldardiry H, Habib E (2018) Carbon capture and sequestration in power generation: review of impacts and opportunities for water sustainability. Energy Sustain Soc 8:1–15. https://doi.org/10.1186/s13705-018-0146-3

Energy Agency (2012) World Energy Outlook

Fasihi M, Efimova O, Breyer C (2019) “Techno-economic assessment of CO2 direct air capture plants. J Clean Prod 224:957–980. https://doi.org/10.1016/j.jclepro.2019.03.086

Feyzi V, Beheshti M, Gharibi Kharaji A (2017) Exergy analysis: a CO2 removal plant using a-MDEA as the solvent. Energy 118:77–84. https://doi.org/10.1016/j.energy.2016.12.020

Ghanbarabadi H et al (2019) “Simulation of CO2 removal from ethane with Sulfinol-M+AMP solvent instead of DEA solvent in the South Pars phases 9 and 10 gas processing facility. Petroleum 5:90–101

Kang G et al (2020) Effect of pressure and temperature on CO2/CH4 competitive adsorption on kaolinite by Monte Carlo simulations. Materials 13(12):2851. https://doi.org/10.3390/ma13122851

Kiełbasa K et al (2021) CO2 adsorption on activated carbons prepared from molasses: a comparison of two and three parametric models. Materials 14(23):7458. https://doi.org/10.3390/ma14237458

Kohmuean P et al (2021) Monte Carlo simulation and experimental studies of CO2, CH4 and their mixture capture in porous carbons. Molecules 26(9):2413. https://doi.org/10.3390/molecules26092413

Kotas TJ (1985) The exergy method of thermal plant analysis. Butterworth-Heinemann, Oxford, England

Leung DYC, Caramanna G, Maroto-Valer MM (2014) An overview of current status of carbon dioxide capture and storage technologies. Renew Sustain Energy Rev 39:426–443. https://doi.org/10.1016/j.rser.2014.07.093

Motazedi K, Abella JP, Bergerson JA (2017) Techno–economic evaluation of technologies to mitigate greenhouse gas emissions at north American refineries. Environ Sci Technol 51(3):1918–1928. https://doi.org/10.1021/acs.est.6b04606

Nejat T et al (2018) Simulated exergy and energy performance comparison of physical–chemical and chemical solvents in a sour gas treatment plant. Chem Eng Res Des 133:40–54

Woodward FI, Bardgett RD, Raven JA, Hetherington AM (2009) Biological approaches to global environment change mitigation and remediation. Curr Biol 19(14):R615–R623. https://doi.org/10.1016/j.cub.2009.06.012

Zhang Y, Chen C-C (2013) “Modeling CO2 absorption and desorption by aqueous monoethanolamine solution with Aspen rate-based model. Energy Proc 37:1584–1596

Acknowledgements

I am grateful to all of those with whom I have had the pleasure to work during this and other related projects. They have provided me extensive personal and professional guidance and taught me a great deal about both scientific research and life in general.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

All authors declare that they have no conflicts of interest.

Additional information

Editorial responsibility: Samareh Mirkia.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Shamsaei, Y., Amidpour, M., Ozgoli, H.A. et al. Performance analysis of power plant designed with a carbon capture unit: study of an oil refinery. Int. J. Environ. Sci. Technol. 20, 2771–2780 (2023). https://doi.org/10.1007/s13762-022-04707-6

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13762-022-04707-6