Abstract

It is important to improve the thermal efficiency and reduce the harmful exhaust emissions of the direct-injection spark-ignition engine. However, this engine has problems such as the emission of particulate matter, including soot, from pool fire with luminous flames. Pool fire is caused by the thermal decomposition of a liquid film, which is created by fuel spray impinging on a piston surface. An understanding of liquid film formation process is important to reduce particulate matter. The purpose of this investigation was to evaluate the effects of injection pressure on fuel spray impingement and liquid film formation process, under engine motoring conditions, using the laser-induced fluorescence method. The fuel consisted of isooctane, 1-octanol and rhodamine B. 1-Octanol was the solvent for rhodamine B, which was illuminated with a neodymium-doped yttrium aluminum garnet laser, causing it to emit red fluorescence at a wavelength of 580 nm; the second harmonic of the laser is at 532 nm. Liquid film images were captured using a high-speed camera. Using image processing, the liquid film area, thickness and mass were estimated. It was found that increasing injection pressure increased the liquid film area, thinned the film and decreased the mass of fuel that remained. In total, 35.6% and 32.5% of the injection mass remained on the piston surface at an injection pressure of 5 and 13 MPa, respectively. In addition, the in-cylinder flow affected the liquid film formation process, stretching the film in the direction of the flow.

Graphical abstract

Similar content being viewed by others

References

Addepalli KS, Mallikarjuna JM (2017) Effect of engine parameters on mixture stratification in a wall-guided GDI engine—a quantitative CFD analysis. SAE Technical Paper, No. 2017-01-0570

Alonso M, Kay PJ, Bowen PJ, Gilchrist R, Sapsford S (2010) A laser induced fluorescence technique for quantifying transient liquid fuel films utilising total internal reflection. Exp Fluids 48:33–142

Chiatti G, Chiavola O, Recco E, Palmieri F (2016) Soot particles experimental characterization during cold start of a micro car engine. Energy Procedia 101:662–669

Costa RC, Sodre JR (2011) Compression ratio effects on an ethanol/gasoline fuelled engine performance. Appl Therm Eng 31(2–3):278–283

Costanzo VS, Heywood JB (2012) Effect of in-cylinder liquid fuel films on engine-out unburned hydrocarbon emissions for an SI engine. SAE Technical Paper, No. 2012-01-1712

Ding CP, Sjöberg M, Vuilleumier D, Reuss DL, Xu H, Bohm B (2018) Fuel film thickness measurements using refractive index matching in a stratified-charge SI engine operated on E30 and alkylate fuels. Exp Fluids 59:59

Glassman I (1989) Soot formation in combustion processes. In: Symposium (international) on combustion, vol 22, No. 1, pp.295–311

Grover RO Jr, Fansler TD, Lippert A, Drake MC, Assanis DN (2020) A numerical–experimental assessment of wall impingement models for spark-ignition direct-injection engines. Int Engine Res 21(2):281–301

Harada J, Tomita T, Mizuno H, Mashiki Z, Ito Y (1997) Development of direct injection gasoline engine. SAE Technical Paper, No. 970540

He X, Ratcliff MA, Zigler BT (2012) Effect of gasoline direct injection engine operating parameters on particle number emissions. Energy Fuels 26(4):2014–2027

Henkel S, Beyrau F, Hardalupas Y, Taylor AMKP (2016) Novel method for the measurement of liquid film thickness during fuel spray impingement on surfaces. Opt Express 24(3):2542–2561

Heywood JB (1994) Combustion and its modeling in spark-ignition engines. In: International symposium COMODIA 94, pp 1–15

Huang Y, Unger N, Harpe K, Heyes C (2020) Global climate and human health effects of the gasoline and diesel vehicle fleets. GeoHealth 4:e2019GH000240

Iwamoto Y, Noma K, Nakayama O, Yamauchi T, Ando H (1997) Development of gasoline direct injection engine. SAE Technical Paper, No. 970541

Jackson NS, Stokes J, Whitaker PA, Lake TH (1997) Stratified and homogeneous charge operation for the direct injection gasoline engine—high power with low fuel consumption and emissions. SAE Technical Paper, No. 970543

Jeon J, Bock N, Kittelson DB, Northrop WF (2018) Correlation of nanoparticle size distribution features to spatiotemporal flame luminosity in gasoline direct injection engines. Int J Engine Res 21(7):1107–1117

Kawahara N, Tomita E, Nakasuji H, Sumida M (2006) PDA measurement of transient spray formed by a DISI multi-hole injector. In: Proceedings of 10th international conference on liquid atomization and spray systems, (ICLASS 2006), pp 1–7

Kawahara N, Mori B, Tomita E (2018) Droplet diameter measurement near a nozzle exit of a gasoline DISI injector using PDA. In: Proceedings of 14th Triennial international conference on liquid atomization and spray systems, (ICLASS 2018), pp 1–8

Ketterer JE, Cheng WK (2014) On the nature of particulate emissions from DISI engines at cold-fast-idle. SAE Technical Paper, No. 2014-01-1368

Ketterer JE, Cheng WK (2019) A study of soot formation in a rapid compression machine at conditions representative of cold-fast-idle in spark ignition engines. Int Engine Res 20(6):670–677

Li X, Xiao D, Parrish SE, Grover RO Jr, Hung DLS, Xu M (2020) Dynamics of spray impingement wall film under cold start conditions. Int Engine Res 21(2):319–329

Montanaro A, Malaguti S, Alfuso S (2012) Wall impingement process of a multi-hole GDI spray: experimental and numerical investigation. SAE Technical Paper, No. 2012-01-1266

Ohsuga M, Shiraishi T, Nogi T, Nakayama Y, Sukegawa Y (1997) Mixture preparation for direct-injection SI engines. SAE Technical Paper, No. 970542

Prakash BC (1990) Automobiles and the “Greenhouse” effect. J Adv Transp 24(3):261–275

Saliba G, Saleh R, Zhao Y, Presto AA, Lambe AT, Frodin B, Sardar S, Maldonado H, Maddox C, May AA, Drozd GT, Goldstein AH, Russell LM, Hagen F, Robinson AL (2017) Comparison of gasoline direct-injection (GDI) and port fuel injection (PFI) vehicle emissions: emission certification standards, cold-start, secondary organic aerosol formation potential, and potential climate impacts. Environ Sci Technol 51(11):6542–6552

Schulz F, Schmidt J, Beyrau F (2015) Development of a sensitive experimental set-up for LIF fuel wall film measurements in a pressure vessel. Exp Fluids 56:98

Senda J, Matsuda T (2003) Modeling on Interaction processes of engine sprays and chamber wall. Atom J ILASS-Jpn 12(39):38–53 (in Japanese)

Stanglmaier RH, Li J, Matthews RD (1999) The effect of in-cylinder wall wetting location on the HC emissions from SI engines. SAE Technical Paper, No. 1999-01-0502.

Stevens E, Steeper R (2001) Piston wetting in an optical DISI engine: fuel films, pool fires, and soot generation. SAE Technical Paper, No. 2001-01-1203

Tomoda T, Sasaki S, Sawada D, Saito A, Sami H (1997) Development of direct injection gasoline engine—study of stratified mixture formation. SAE Trans 106:759–766

Tomoda T, Kubota M, Shimizu R, Nomura Y (2003) Numerical analysis of mixture formation of a direct injection gasoline engine. JSME Int J Ser B 46(1):2–9

Wang Z, Liu H, Reitz RD (2017) Knocking combustion in spark-ignition engines. Prog Energy Combust Sci 61:78–112

Zhao Z, Zhu X, Naber J, Lee SY (2020) Assessment of impinged flame structure in high-pressure direct diesel injection. Int J Engine Res 21(2):391–405

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

None declared under financial, general, and institutional conflict of interests.

Additional information

Editorial responsibility: Samareh Mirkia.

Appendix

Appendix

A. Measurement uncertainty of liquid film thickness

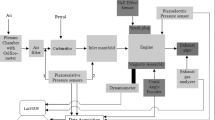

The liquid film formation process could be captured and analyzed from below the piston with the RCEM. Good reliability of the measurement method and data analysis is necessary. However, when using the RCEM, the effects of in-cylinder pressure and temperature changes, in-cylinder flow and piston movement must be considered, which makes it difficult to evaluate reliability. In addition, using the RCEM, only the view from below the piston is available. For these reasons, the reliability of the experimental method and data was investigated out under atmospheric conditions.

Figure 10 shows a schematic diagram of the experimental setup under atmospheric conditions. Each component and the optical layout were the same in the motoring conditions in RCEM. Figure 11 shows the \({\delta }_{\mathrm{nfl}}\) (liquid film thickness) distribution at TDC timing for each value of Pinj. The liquid film thickness distribution was determined using the captured images and calibration equation as shown in Fig. 2. As Pinj increased, \({\delta }_{\mathrm{nfl}}\) decreased. Comparing the results for Pinj = 5 and 13 MPa, the maximum values of \({\delta }_{\mathrm{nfl}}\) were approximately 50 and 20 μm, respectively. By contrast, the minimum value of \({\delta }_{\mathrm{nfl}}\) was approximately 10 μm in both cases. It is assumed that \(V\) affected the distribution; as Pinj increased, so did \(V\); thus, during spray impingement, the increased \(V\) pushed the liquid film over a wider and longer area. Therefore, the film became thinner and its area increased as Pinj increased.

Figure 12 shows the liquid film mass at TDC timing for each value of Pinj. For Pinj = 5 MPa, 0.82 mg formed on the piston surface, which was 18.0% of the total injected mass. By contrast, for Pinj = 13 MPa, 0.60 mg formed (13.2% of the injection mass). From the results of the side-view visualization, as Pinj increased, so too did the rebounded fuel. In addition, considering the breakup model, increasing Pinj increased the \({\mathrm{We}}_{n}\) of each fuel droplet, so they tended to splash rather than deposit. For these reasons, as Pinj increased, the liquid film mass decreased.

The purpose of this experiment was to evaluate the measurement method. The liquid film formation process was captured from below and beside the piston using a high-speed color camera. Comparing our results with relevant studies that used the LIF method (Schulz et al. 2015; Alonso et al. 2010), the \({\delta }_{\mathrm{nfl}}\) distributions matched and the maximum \({\delta }_{\mathrm{nfl}}\) values were almost the same. Therefore, it is considered the measurement method in this study to be sufficiently reliable and conducted a further experiment using the RCEM.

Rights and permissions

About this article

Cite this article

Tomomatsu, Y., Kawahara, N. & Tomita, E. Fuel spray impingement and liquid film formation in a gasoline direct-injection spark-ignition engine. Int. J. Environ. Sci. Technol. 20, 477–488 (2023). https://doi.org/10.1007/s13762-022-04010-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13762-022-04010-4