Abstract

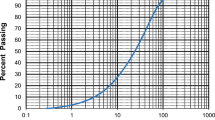

Cemented paste backfill system used for the storage of tailings underground also serves as support against subsidence due to roof loads. Therefore, paste backfill materials should be optimized according to strength, environment, and cost requirements. The main purpose of this study is to determine the ratio and optimal particle size distribution of zeolite which is one of the natural pozzolanic materials and can substitute cement in paste backfill. As a result of the experiments without zeolite, it was determined that paste backfill materials with the cement ratio of 9% and 11% can be used for ground support instead of the cemented paste backfill reference samples with 80% solid content. Then, zeolite-substituted samples were prepared in 2 different particle sizes of − 90 μm and − 180 μm at cement ratios of 5%, 10%, 15%, and 20%. Then, the effects of the paste backfill materials on the strength of curing periods of 28, 56, and 90 days were examined. As a result, it was found that 9% cemented paste backfills with 15% zeolite substitutes (− 90 μm) and 11% cemented paste backfills with 10% zeolite substitutes (− 180 μm) could be used in paste backfill. Also, 11% cemented paste backfills with 10% zeolite substitutes (− 180 μm) provide better strength depending on the curing times.

Similar content being viewed by others

References

Abdul-Hussain N, Fall M (2011) Unsaturated hydraulic properties of cemented tailings backfill that contains sodium silicate. Eng Geol 123(4):288–301

Adiguzel D, Bascetin A (2019) The investigation of effect of particle size distribution on flow behavior of paste tailings. J Environ Manag 243:393–401

Akgun Y (2017) Determination of pozzolanic activity for using natural zeolite analcime in sustainability additive cement products. Periodicals Eng Nat Sci 5(2):187–193

ASTM C143 2015) Standard test method for slump of hydraulic-cement concrete. ASTM International, West Conshohocken, PA

ASTM C311 (2018) Standard test methods for sampling and testing fly ash or natural pozzolans for use in portland-cement concrete. ASTM International, West Conshohocken, PA

ASTM C39 (2018) Standard test method for compressive strength of cylindrical concrete specimens. ASTM International, West Conshohocken, PA

ASTM C430 (2017) Standard test method for fineness of hydraulic cement by the 45-μm (No. 325) sieve. ASTM International, West Conshohocken, PA

ASTM C618 (2019) Standard specification for coal fly ash and raw or calcined natural pozzolan for use in concrete. ASTM International, West Conshohocken, PA

Belem T, Benzaazoua M (2008) Design and application of underground mine paste backfill technology. Geotech Geol Eng 26(2):147–174

Benzaazoua M, Belem T, Bussière B. (2002) Chemical factors that influence the performance of mine sulphidic paste backfill. Cem Concr Res 32(7):1133–1144

Benzaazoua M, Fall M, Belem T (2004) A contribution to understanding the hardening process of cemented pastefill. Miner Eng 17(2):141–152

Bilgin O, Kantarci S (2018) Investigation of technological properties of observed hoylandit /clinoptilolite zeolite formation near Bigadiç (Balikesir, Turkey). J BAUN Inst Sci Technol 20(1):589–601

Bowker LN, Chambers DM (2015) The risk, public liability, & economics of tailings storage facility failures. Research Paper. Stonington, ME

Bowker LN, Chambers DM (2016) Root causes of tailings dam overtopping: the economics of risk & consequence. Protections 2016 2nd ınternational seminar on dam protection against overtopping Ft. Collins, Colorado, USA, 7–9 September 2016. ISBN: 978-1-1889143-27-9

Brackebusch FW (1994) Basics of paste backfill systems. Min Eng 46:1175–1178

Burriesci N, Arcoraci C, Giordano N, Antonucci PL (1985) Zeolites from pumice and tuffas evaluation of pozzolanic cement constituents. Zeolites 5:96–100

Canpolat F, Yilmaz K, Mkose M, Sumer M, Yurdusev MA (2004) Use of zeolite, coal bottom ash and fly ash as replacement materials in cement production. Cem Concr Res 34:731–735

Cihangir F, Ercikdi B, Kesimal A, Deveci H, Erdemir F (2015) Paste backfill of high-sulphide mill tailings using alkali-activated blast furnace slag: effect of activator nature, concentration and slag properties. Miner Eng 83:117–127

Clark CC, Vickery JD, Backer RR (1995) Transport of total tailings paste backfill: results of full-scale pipe test loop pumping tests. Report of investigation, RI 9573, USBM, 37 pp

Dong Q, Liang B, Jia L, Jiang L (2019) Effect of sulfide on the long-term strength of lead-zinc tailings cemented paste backfill. Constr Build Mater 200:436–446

Doula MK, Ioannou A (2003) The effect of electrolyte anion on Cu adsorption–desorption by clinoptilolite. Microporous Mesoporous Mater 58:115–130

Eker H (2019) Determination of optimum design parameters in deposition of metalic process tailings by paste backfill method, Ph.D. thesis, Advisor Prof. Dr. Atac Bascetin. Istanbul University-Cerrahpasa Institute of Graduate Studies

Erdem E, Karapinar N, Donat R (2004) The removal of heavy metal cations by natural zeolites. J Coll Inter Sci 280:309–314

Fall M, Pokharel M (2010) Coupled effects of sulphate and temperature on the strength development of cemented tailings backfills: portland cement-paste backfill. Cement Concr Compos 32(10):819–828

Fall M, Benzaazoua M, Ouellet S (2005) Experimental characterization of the effect of tailings fineness and density on the quality of cemented paste backfill. Miner Eng 18(1):41–44

Fall M, Benzaazoua M, Saa EG (2008) Mix proportioning of underground cemented tailings backfill. Tunn Undergr Space Technol 23(1):80–90

Fall M, Adrien D, Célestin JC, Pokharel M, Touré M (2009) Saturated hydraulic conductivity of cemented paste backfill. Miner Eng 22(15):1307–1317

Fall M, Benzaazoua M, Ouellet S (2004) Effect of tailings properties on paste backfill performance, In: The 8th international symposium on mining with backfill, Beijing, China, pp 193–202

Ghirian A, Fall M (2015) Coupled behavior of cemented paste backfill at early ages. Geotech Geol Eng 33(5):1141–1166

Ghirian A, Fall M (2016) Long-term coupled behaviour of cemented paste backfill in load cell experiments. Geomech Geoeng 11(4):237–251

Grice AG (1998) Underground mining with backfill. The 2nd annual summit—mine tailings disposal systems, 24–25 November 1998, Brisbane, Australia, 14 p

Hassani F, Archibald J (1998) Mine backfill. In: Canadian Institute of Mine, Metallurgy and Petroleum, Published on CD-ROM Proceedings, Canada, 263p

Hefni MA (2014) An investigation into the develpoment and potential of foam minefill, Ph.D. thesis, McGill University

Huang S, Xia K, Qiao L (2011) (2011) Dynamic tests of cemented paste backfill: effects of strain rate, curing time, and cement content on compressive strength. J Mater Sci 46:5165–5170

Ikotun BD (2009) The effect of modified zeolite additive as a cement and concrete improver. M.Sc. thesis. Johannesburg: University of the Witwatersrand.

ISO 14688-2 (2004) Geotechnical investigation and testing—ıdentification and classification of soil—part 2: principles for a classification

Jiang H, Fall M, Cui L (2017) Freezing behaviour of cemented paste backfill material in column experiments. Constr Build Mater 147:837–846

Jung SJ, Biswas K (2002) Review of current high density paste fill and its technology. Miner Resour Eng 11(2):18

Kesimal A, Yilmaz E, Ercikdi B, Alp I, ve Deveci, H. (2005) Effect of properties of tailings and binder on the short-and long-term strength and stability of cemented paste backfill. Mater Lett 59:3703–3709

Koohestani B, Bussière B, Belem T, Koubaa A (2017) Influence of polymer powder on properties of cemented paste backfill. Int J Miner Process 167:1–8

Li T, Singh U, Coxon J, Grice TG, Sainsbury D (2002) Development and application of paste fill using dry tailings. In: First International seminar on deep and high stress mining, Perth, 10 pp

Li W, Fall M (2016) Sulphate effect on the early age strength and self-desiccation of cemented paste backfill. Constr Build Mater 106:296–304

Morali N (2006) Investigation of zinc and lead removal from aqueous solutions using clinoptilolite. M.Sc. thesis, Supervisor: Assist. Prof. Dr. Ipek Imamoglu, METU

Mozgawa W, Bajda T (2005) Spectroscopic study of heavy metals sorption on clinoptilolite. Phys Chem Minerals 31:709–713

Ouattara D, Yahia A, Mbonimpa M, Belem T (2017) Effects of superplasticizer on rheological properties of cemented paste backfills. Int J Miner Process 161:28–40

Ouattara D, Mbonimpa M, Yahia A, Belem T (2018) Assessment of rheological parameters of high density cemented paste backfill mixtures incorporating superplasticizers. Constr Build Mater 190:294–307

Shaheen SM, Derbalah AS, Moghanm FS (2012) Removal of heavy metals from aqueous solution by zeolite in competitive sorption system. Int J Environ Sci Dev 3(4):362–367

Tariq A, Nehdi M (2007) Developing durable paste backfill from sulphidic tailings. Proc İnst Civil Eng Waste Resour Manag 160(4):155–166

Trgo M, Peric J (2003) Interaction of the zeolitic tuff with Zn-containing simulated pollutant solutions. J Colloid Interface Sci 260:166–175

Wang Y, Wu A, Wang S, Wang H, Yang L, Wang Y, Ruan ZE (2017) Correlative mechanism of hydraulic-mechanical property in cemented paste backfill. J Wuhan Univ Technol Mater Sci Ed 32(3):579–585

WISE (2020) World information service on energy uranium project, chronology of major tailings dam failures, from 1960. http://www.wise-uranium.org/mdaf.html (March 16, 2020).

Wu A, Wang Y, Wang H, Yin S, Miao X (2015) Coupled effects of cement type and water quality on the properties of cemented paste backfill. Int J Miner Process 143:65–71

Wu J, Feng M, Chen Z, Mao X, And HG, Wang Y (2018) Particle size distribution effects on the strength characteristic of cemented paste backfill. Minerals 8:322

Yilmaz E, Benzaazoua M, Belem T, Bussière B (2009) Effect of curing under pressure on compressive strength development of cemented paste backfill. Miner Eng 22(9–10):772–785

Yilmaz E, Belem T, Bussière B, Benzaazoua M (2011) Relationships between microstructural properties and compressive strength of consolidated and unconsolidated cemented paste backfills. Cement Concr Compos 33(6):702–715

Yilmaz E, Belem T, Benzaazoua M (2015) Specimen size effect on strength behavior of cemented paste backfills subjected to different placement conditions. Eng Geol 185:52–62

Acknowledgments

The authors wish to thank all who assisted in conducting this work.

Funding

No funding was received to assist with the preparation of this manuscript.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflicts of interests

The author has no conflicts of interest to declare that are relevant to the content of this article.

Additional information

Editorial responsibility: S. Mirkia.

Rights and permissions

About this article

Cite this article

Tuylu, S. Effect of different particle size distribution of zeolite on the strength of cemented paste backfill. Int. J. Environ. Sci. Technol. 19, 131–140 (2022). https://doi.org/10.1007/s13762-021-03659-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13762-021-03659-7