Abstract

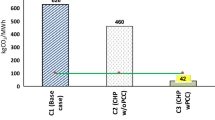

Coke oven gas (COG) is used to generate energy for the iron-making process by burning; however, from an environmental point of view, it can be converted to methanol (MeOH) for effective utilization. This study designs a large-scale process for the MeOH production from COG based on the validated kinetic studies and performs a life cycle assessment (LCA) of the proposed process. The LCA results are compared with those of the conventional option of COG energy generation combined with primary source-based MeOH production by defining the “cradle-to-gate” system boundary and applying the ReCiPe 2016 Midpoint level methodology using SimaPro 9.0 software. Consequently, the LCA results show that the global warming (GW) and fossil resource scarcity (FRS) of the new COG process are lower than those of the conventional option by 64.8% and 38.0%, respectively. The GW and FRS impacts of the new COG process are dominated by the displacement effect of the heat generation of COG by the primary source. Using wood chips as a primary source could reduce both GW and FRS, leading to a carbon-negative (− 0.51 kg CO2 eq.) COG process.

Similar content being viewed by others

Abbreviations

- COG:

-

Coke oven gas

- FRS:

-

Fossil resource scarcity

- GW:

-

Global warming

- HC:

-

Hard coal

- HEN:

-

Heat exchanger network

- LCA:

-

Life cycle assessment

- M&E:

-

Materials and energies

- NG:

-

Natural gas

- WC:

-

Wood chips

References

Bermúdez JM, Fidalgo B, Arenillas A, Menéndez JA (2012) CO2 reforming of coke oven gas over a Ni/γAl2O3 catalyst to produce syngas for methanol synthesis. Fuel 94:197–203

Bermúdez JM, Arenillas A, Luque R, Menéndez JA (2013a) An overview of novel technologies to valorise coke oven gas surplus. Fuel Process Technol 110:150–159

Bermúdez JM, Ferrera-Lorenzo N, Luque S, Arenillas A, Menéndez JA (2013b) New process for producing methanol from coke oven gas by means of CO2 reforming. Comparison with conventional process. Fuel Process Technol 115:215–221

Byun J, Han J (2020) Sustainable development of biorefineries: integrated assessment method for co-production pathways. Energy Environ Sci 13:2233–2242

Byun J, Kwon O, Park H, Han J (2021) Food waste valorization to green energy vehicles: sustainability assessment. Energy Environ Sci. https://doi.org/10.1039/D1EE00850A

Finkbeiner M, Inaba A, Tan R, Christiansen K, Klüppel H-J (2006) The new international standards for life cycle assessment: ISO 14040 and ISO 14044. Int J Life Cycle Assess 11:80–85

Goyal R, Gray S, Kallhauge AC, Nierop S, Berg T, Leuschner P (2018) State and trends of carbon pricing 2018. The World Bank, Washington

Graaf GH, Scholtens H, Stamhuis EJ, Beenackers AACM (1990) Intra-particle diffusion limitations in low-pressure methanol synthesis. Chem Eng Sci 45:773–783

Hu C, Han X, Li Z, Zhang C (2009) Comparison of CO2 emission between COREX and blast furnace iron-making system. J Environ Sci 21:S116–S120

Huijbregts M, Steinmann Z, Elshout P, Stam G, Verones F, Vieira M, Hollander A, Zijp M, Van Zelm R (2016) ReCiPe 2016: a harmonized life cycle impact assessment method at midpoint and endpoint level report I: characterization.

Kim D, Han J (2020) Techno-economic and climate impact analysis of carbon utilization process for methanol production from blast furnace gas over Cu/ZnO/Al2O3 catalyst. Energy 198:117355

Lee J-K, Lee I-B, Han J (2019) Techno-economic analysis of methanol production from joint feedstock of coke oven gas and basic oxygen furnace gas from steel-making. J Ind Eng Chem 75:77–85

Li C, Bai H, Lu Y, Bian J, Dong Y, Xu H (2018a) Life-cycle assessment for coal-based methanol production in China. J Clean Prod 188:1004–1017

Li J, Ma X, Liu H, Zhang X (2018b) Life cycle assessment and economic analysis of methanol production from coke oven gas compared with coal and natural gas routes. J Clean Prod 185:299–308

Olah GA (2005) Beyond oil and gas: the methanol economy. Angew Chem Int Ed 44:2636–2639

Park H, Byun J, Han J (2021) Economically feasible thermochemical process for methanol production from kenaf. Energy 230:120729

Qin Z, Zhai G, Wu X, Yu Y, Zhang Z (2016) Carbon footprint evaluation of coal-to-methanol chain with the hierarchical attribution management and life cycle assessment. Energy Convers Manage 124:168–179

Razzaq R, Li C, Zhang S (2013) Coke oven gas: availability, properties, purification, and utilization in China. Fuel 113:287–299

Renó MLG, Lora EES, Palacio JCE, Venturini OJ, Buchgeister J, Almazan O (2011) A LCA (life cycle assessment) of the methanol production from sugarcane bagasse. Energy 36:3716–3726

Śliwińska A, Burchart-Korol D, Smoliński A (2017) Environmental life cycle assessment of methanol and electricity co-production system based on coal gasification technology. Sci Total Environ 574:1571–1579

Thonemann N, Maga D, Petermann C (2018) Handling of multi-functionality in life cycle assessments for steel mill gas based chemical production. Chem Ing Tech 90:1576–1586

Üçtuğ FG, Ağralı S, Arıkan Y, Avcıoğlu E (2014) Deciding between carbon trading and carbon capture and sequestration: an optimisation-based case study for methanol synthesis from syngas. J Environ Manag 132:1–8

Verones F et al (2017) LCIA framework and cross-cutting issues guidance within the UNEP-SETAC Life Cycle Initiative. J Clean Prod 161:957–967

Yi Q, Gong M-H, Huang Y, Feng J, Hao Y-H, Zhang J-L, Li W-Y (2016) Process development of coke oven gas to methanol integrated with CO2 recycle for satisfactory techno-economic performance. Energy 112:618–628

Yin X, Leung DYC, Chang J, Wang J, Fu Y, Wu C (2005) Characteristics of the synthesis of methanol using biomass-derived syngas. Energy Fuels 19:305–310

Acknowledgements

This research was supported by ‘‘Carbon to X Project’’ through the National Research Foundation of Korea (NRF) funded by the Ministry of Science and ICT, Republic of Korea (2020M3H7A1096361), and Development of Platform for Future New Growth Engines CO2 High-Value Added Commercialization Program through Korea Institute for Advancement of Technology (KIAT) funded by the Ministry of Trade, Industry and Energy (No. 1415164998-R0006251).

Author information

Authors and Affiliations

Contributions

DK took part in investigation, writing—original draft preparation, reviewing, and editing. JH involved in conceptualization, investigation, writing—original draft preparation, reviewing, and editing.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Editorial responsibility: Q. Aguilar-Virgen.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Kang, D., Han, J. Environmental analysis of methanol production from coke oven gas. Int. J. Environ. Sci. Technol. 19, 5849–5856 (2022). https://doi.org/10.1007/s13762-021-03525-6

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13762-021-03525-6