Abstract

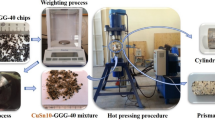

The purpose of this study is to produce composite materials by utilizing the waste metallic chips. In this context, the metal matrix composite materials (MMCs) were produced at different production pressures and the effects of the different pressures on mechanical properties of MMCs were investigated. In the present investigation, spheroidal graphite cast iron (GGG-40) was used as reinforcement material in bronze (CuSn10) matrix system. The MMCs were produced by hot press with 20 wt% GGG-40 reinforcement ratio. The total time required for the production of one specimen was selected as 25 min and temperature was settled at 400 °C. In order to determine mechanical properties and consolidation mechanism of MMCs, Brinell and micro-Vickers hardness, porosity, compression and X-ray diffraction tests were conducted. In addition, microstructure views were examined to determine the consolidation quality of metallic chips. According to experimental results, it was observed that waste metallic chips can be successfully recycled into MMC final parts with approximately 40% porosity and almost 100% strength and 150% hardness with respect to bulk CuSn10 materials. Most of the presented studies in the literature present information about properties of MMCs fabricated by conventional production methods. However, no available data are found about the recycling of bronze-based MMCs which make this study more original. It is also shown in this study that waste metallic chips can be utilized by proposed recycling methodology, which is environmentally friendly in comparison with conventional recycling methods producing harmful gases for earth atmosphere.

Similar content being viewed by others

References

Abd El Aal MI, Yoon EY, Kim HS (2013) Recycling of AlSi8Cu3 alloy chips via high pressure torsion. Mater Sci Eng Struct Mater Properties Microstruct Process 560:121–128

Aslan A (2014) Production of metal matrix composites by recycling of waste metal chips and their mechanical properties. Ms thesis, Selçuk University, Department of Mechanical Engineering, Konya

Aslan A, Sahin OS, Salur E, Gunes A, Akdemir A, Karadag HB (2015) A new method for recycling of metal chips. J Selçuk Univ Nat Appl Sci 4(1):1–12

Aslan A, Salur E, Güneş A, Şahin ÖS, Karadağ HB, Akdemir A (2018) Production and mechanical characterization of prismatic shape machine element by recycling of bronze and cast-iron chips. J Facul Eng Archit Gazi Univ 33(3):1013–1027

da Costa CE, Zapata WC, Parucker ML (2003) Characterization of casting iron powder from recycled swarf. J Mater Process Technol 143:138–143

Dobrzanski LA, Drak M (2004) Structure and properties of composite materials with polymer matrix reinforced Nd–Fe–B hard magnetic nanostructured particles. J Mater Process Technol 157:650–657

El-Daly AA, Abdelhameed M, Hashish M, Daoush WM (2013) Fabrication of silicon carbide reinforced aluminum matrix nanocomposites and characterization of its mechanical properties using non-destructive technique. Mater Sci Eng Struct Mater Properties Microstruct Process 559:384–393

Fogagnolo J, Ruiz-Navas E, Simón M, Martinez M (2003) Recycling of aluminium alloy and aluminium matrix composite chips by pressing and hot extrusion. J Mater Process Technol 143:792–795

German RM (2005) Powder metallurgy and particulate materials processing: the processes, materials, products, properties, and applications. Metal powder industries federation Princeton

Ghori N-H, Ghori T, Hayat MQ, Imadi SR, Gul A, Altay V, Ozturk M (2019) Heavy metal stress and responses in plants. Int J Environ Sci Technol 16:1807–1828

Gronostajski J, Matuszak A (1999) The recycling of metals by plastic deformation: an example of recycling of aluminium and its alloys chips. J Mater Process Technol 93:35–41

Gronostajski JZ, Kaczmar JW, Marciniak H, Matuszak A (1997) Direct recycling of aluminium chips into extruded products. J Mater Process Technol 64(1–3):149–156

Gronostajski J, Marciniak H, Matuszak A (2000) New methods of aluminium and aluminium-alloy chips recycling. J Mater Process Technol 106(1–3):34–39

Guluzade R, Avci A, Demirci MT, Erkendirci OF (2013) Fracture toughness of recycled AISI 1040 steel chip reinforced AlMg1SiCu aluminum chip composites. Mater Des 52:345–352

He J, Duan C, He Y, Zhang H (2015) Recovery of valuable metal concentrate from waste printed circuit boards by a physical beneficiation technology. Int J Environ Sci Technol 12(8):2603–2612

Jafari M, Abbasi MH, Enayati MH, Karimzadeh F (2012) Mechanical properties of nanostructured Al2024-MWCNT composite prepared by optimized mechanical milling and hot pressing methods. Adv Powder Technol 23(2):205–210

Juškėnas R, Mockus Z, Kanapeckaitė S, Stalnionis G, Survila A (2006) XRD studies of the phase composition of the electrodeposited copper-rich Cu–Sn alloys. Electrochim Acta 52(3):928–935

Kar D, Sur P, Mandai SK, Saha T, Kole RK (2008) Assessment of heavy metal pollution in surface water. Int J Environ Sci Technol 5(1):119–124

Karadağ H (2012) Productıon and mechanical properties of steel/bronze chips composite. Ph.D. thesis. Selçuk University, Department of Mechanical Engineering, Konya

Kong G, White R (2010) Toward cleaner production of hot dip galvanizing industry in China. J Clean Prod 18(10–11):1092–1099

Li T, Yi DQ, Hu J, Xu J, Liu JL, Wang B (2017) Surface modification of h-BN and its influence on the mechanical properties of CuSn10/h-BN composites. J Alloys Compd 723:345–353

Liu J, Diamond J (2005) China’s environment in a globalizing world. Nature 435(7046):1179

Neto B, Kroeze C, Hordijk L, Costa C (2009) Inventory of pollution reduction options for an aluminium pressure die casting plant. Resour Conserv Recycl 53(6):309–320

Reza R, Singh G (2010) Heavy metal contamination and its indexing approach for river water. Int J Environ Sci Technol 7(4):785–792

Şahin ÖS, Güneş A, Aslan A, Salur E, Karadağ HB, Akdemir A (2017) Low-velocity impact behavior of porous metal matrix composites produced by recycling of bronze and iron chips. Iran J Sci Technol Trans Mech Eng pp 1–8

Saleh TA (2015a) Isotherm, kinetic, and thermodynamic studies on Hg(II) adsorption from aqueous solution by silica-multiwall carbon nanotubes. Environ Sci Pollut Res 22(21):16721–16731

Saleh TA (2015b) Mercury sorption by silica/carbon nanotubes and silica/activated carbon: a comparison study. J Water Supply Res Technol Aqua 64(8):892–903

Saleh TA (2016) Nanocomposite of carbon nanotubes/silica nanoparticles and their use for adsorption of Pb(II): from surface properties to sorption mechanism. Desalinat Water Treat 57(23):10730–10744

Saleh TA (2017) Advanced nanomaterials for water engineering, treatment, and hydraulics. IGI Global, Pennsylvania

Saleh TA (2018) Simultaneous adsorptive desulfurization of diesel fuel over bimetallic nanoparticles loaded on activated carbon. J Clean Prod 172:2123–2132

Saleh TA, Gupta VK (2016) Nanomaterial and polymer membranes: synthesis, characterization, and applications. Elsevier, Amsterdam

Salur E (2017) Investigation of machinability properties of metal matrix composites produced by recycling of waste metal chips. Ms thesis, Selçuk University, Department of Mechanical Engineering, Konya

Salur E, Aslan A, Kuntoglu M, Gunes A, Sahin OS (2019) Experimental study and analysis of machinability characteristics of metal matrix composites during drilling. Compos Part B Eng 166:401–413

Szczepanik S, Sleboda T (1996) The influence of the hot deformation and heat treatment on the properties of P/M Al–Cu composites. J Mater Process Technol 60(1–4):729–733

Tang F, Anderson IE, Gnaupel-Herold T, Prask H (2004) Pure Al matrix composites produced by vacuum hot pressing: tensile properties and strengthening mechanisms. Mater Sci Eng Struct Mater Properties Microstruct Process 383(2):362–373

Witte F, Feyerabend F, Maier P, Fischer J, Störmer M, Blawert C, Dietzel W, Hort N (2007) Biodegradable magnesium–hydroxyapatite metal matrix composites. Biomaterials 28(13):2163–2174

Wu SY, Ji ZS, Zhang TL (2009) Microstructure and mechanical properties of AZ31B magnesium alloy recycled by solid-state process from different size chips. J Mater Process Technol 209(12–13):5319–5324

Ying T, Zheng MY, Hu XS, Wu K (2010) Recycling of AZ91Mg alloy through consolidation of machined chips by extrusion and ECAP. Trans Nonferrous Met Soc China 20:S604–S607

Acknowledgements

This study was supported by the Scientific and Technological Research Council of Turkey (TUBITAK) [Grant Number 113M141] and Scientific Research Projects Coordination Unit (SRPCU) [Project Number 10201039].

Author information

Authors and Affiliations

Corresponding author

Additional information

Editorial responsibility: J Aravind.

Rights and permissions

About this article

Cite this article

Aslan, A., Salur, E., Gunes, A. et al. The mechanical properties of composite materials recycled from waste metallic chips under different pressures. Int. J. Environ. Sci. Technol. 16, 5259–5266 (2019). https://doi.org/10.1007/s13762-019-02317-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13762-019-02317-3