Abstract

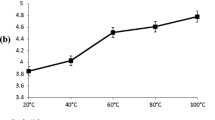

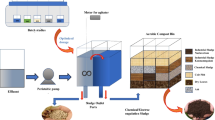

Among dairy effluents, bactofugate (B) and decreaming racking water (D) were identified as the most polluting due to their organic load content expressed in the chemical oxygen demand (156–240 g·L−1). Joining the plant wastewater, such effluents contribute to the increase of the polluting load of the wastewater treatment plant input which disturbs the treatment performance. This work proposes an upstream segregation of those dairy effluents for combined physical–chemical and biological treatment. An experimental design was proposed to investigate initial pH, applied temperature and exposure time factor effects on the thermal coagulation process. The fermentation of the resulted supernatants using Lactobacillus lactis ssp. lactis was performed. The optimized thermal coagulation pretreatment was obtained at (pH; T(°C); t(min)): 6, 60 °C and 5 min, with both (B) and (D) effluents. Resulted clarified whey sugar, protein and fat contents were assessed. The physical–chemical treatment resulted in considerable organic matter removal: 45% for (B) samples and 31% for (D) samples of proteins content and almost the total fat content. However, there is no considerable effect on the sugar content reduction, which remains responsible for the major fraction of the whey residual chemical oxygen demand (COD). Clarified whey fermentation using Lactococcus lactis ssp. lactis strain induced important sugar consumption rates. Therefore, important sugar consumption rates were recorded and the COD removal efficiency was improved. The recorded global COD removal efficiency was of about 93%. The proposed combined physical–chemical and biological processes for dairy effluents pretreatment allowed not only to reduce the effluents polluting load, but also to valorize wheys by producing valuable components.

Similar content being viewed by others

References

AFNOR (1971) Lait. Détermination de la teneur en lactose NF V 04-213

AFNOR (1980) Lait. Détermination de la matière sèche. NF VO4 207. AFNOR, Paris: Normalisation française

AFNOR (2001) Lait—Détermination de la teneur en matière grasse—Méthode gravimétrique (méthode de référence). NF EN ISO 1211

Alonso S, Herrero M, Rendueles M, Díaz M, (2010) Residual yoghurt whey for lactic acid production. Biomass Bioenerg 34:931–938

Alonso S, Herrero M, Rendueles M, Díaz M (2014) Physiological heterogeneity in Lactobacillus casei fermentations on residual yoghurt whey. Process Biochem 49:732–739

Belwarda K (2012) Statistical data. Centrale Laitière du Cap Bon, Tunisia

Beszedes S, Szabo G, Géczi G (2012) Application of thermal and microwave pre-treatments for dairy wastewater sludge. Int J Eng 3:230–235

Corrêa APF, Daroit DJ, Fontoura R, Meira SMM, Segalin J, Brandelli A (2014) Hydrolysates of sheep cheese whey as a source of bioactive peptides with antioxidant and angiotensin-converting enzyme inhibitory activities. Peptides 61:48–55

Corredig M, Dalgleish DG (1996) Effect of temperature and pH on the interactions of whey proteins with casein micelles in skim milk. Food Res Int 29:49–55

Deshayes CMP (1980) Utilisation de modèles mathématiques pour l’optimisation en fermentation. Bulletin de la Société Chimique de France 1:24–34

Dimitrellou D, Kourkoutas Y, Banat IM, Marchant R, Koutinas AA (2007) Whey-cheese production using freeze–dried kefir culture as a starter. J Appl Microbiol 103:1170–1183

Fauquant J, Vieco E, Brule G, Maubois JL (1985) Clarification des lactosérums doux par agrégation thermocalcique de la matière grasse résiduelle. Lait 65:1–20

Fergala M (1995) The anaerobic treatment of complex wastewater. Ph.D. Thesis. Van Hall Institute, Groningen, Netherlands

FIL105-ISO488 (2008) Lait—Détermination de la teneur en matière grasse—Butyromètres Gerber

Gannoun H, Khelifi E, Bouallagui H, Touhami Y, Hamdi M (2008) Ecological clarification of cheese whey prior to anaerobic digestion in upflow anaerobic filter. Bioresour Technol 99:6105–6111

Gavala HN, Skiadas IV, Lyberatos G (1999) On the performance of a centralised digestion facility receiving seasonal agroindustrial wastewaters. Water Sci Technol 40:339–346

Group WB (1999) Project Guidelines: Dairy Industry. In: Fleming C, Danczyk K and Hitchcock V (eds) Pollution Prevention and Abatement handbook, Toward Cleaner Production. World Bank Publications, Washington, pp 295–297

Hadiyanto Ariyanti D, Aini AP, Pinundi DS (2014) Optimization of ethanol production from whey through fed-batch fermentation using Kluyveromyces marxianus. Energ Proc 47:108–112

Harta O, Iconomopoulou M, Bekatorou A, Nigam P, Kontominas M, Koutinas AA (2004) Effect of various carbohydrate substrates on the production of kefir grains for use as a novel baking starter. Food Chem 88:237–242

Kasmi M (2016) Biological processes as promoting way for both treatment and valorization of dairy industry effluents: a review. Waste Biomass Valor. doi:10.1007/s12649-016-9795-9797

Kasmi M, Snoussi M, Dahmeni A, Ben Amor M, Hamdi M, Trabelsi I (2016) Use of thermal coagulation, separation, and fermentation processes for dairy wastewater treatment. Des Water Treat 57:13166–13174

Kasmi M, Hamdi M, Trabelsi I (2017) Eco-friendly process combining physical-chemical and biological technics for the fermented dairy products waste pretreatment and reuse. Water Sci Technol 75:39–47

Kosseva MR (2011) Management and processing of food wastes. In: Moo-Young M (ed) Comprehensive biotechnology, environmental biotechnology and safety, vol 6. Elsevier, Hoboken

Kourkoutas Y, Xolias V, Kallis M, Bezirtzoglou E, Kanellaki M (2005) Lactobacillus casei cell immobilization on fruit pieces for probiotic additive, fermented milk and lactic acid production. Process Biochem 40:411–416

Kourkoutas Y, Kandylis P, Panas P, Dooley JS, Nigam P, Koutinas AA (2006) Evaluation of freeze–dried kefir coculture as starter in feta-type cheese production. Appl Environ Microbiol 72:6124–6135

Li Y, Dalgleish D, Corredig M (2015) Influence of heating treatment and membrane concentration on the formation of soluble aggregates. Food Res Int 76:309–316

Mawson AJ (1994) Bioconversions for whey utilization and waste abatement. Bioresour Technol 47:195–203

Moulin G, Ratomahenina R, Galzy P, Boze M (1976) Sélection de levure en vue de la culture sur lactosérum. Lait 56:135–142

Munavalli GR, Saler PS (2009) Treatment of dairy wastewater by water hyacinth. Water Sci Technol 59:713–722

Nasirahmadi S, Safekordi AA (2011) Whey as a substrate for generation of bioelectricity in microbial fuel cell using E. coli. Int J Environ Sci Technol 8:823–830

Oldfield DJ, Singh H, Taylor MW, Pearce KN (2000) Heat-induced interactions of β-lactoglobulin and α-lactalbumin with the casein micelle in pH-adjusted skim milk. Int Dairy J 10:509–518

Panesar PS, Kennedy JF, Gandhi DN, Bunko K (2007) Bioutilisation of whey for lactic acid production. Food Chem 105:1–14

Pescuma M, Hebert EM, Mozzi F, Font de Valdez G (2008) Whey fermentation by thermophilic lactic acid bacteria: evolution of carbohydrates and protein content. Food Microbiol 25:442–451

Prakash N, Garg A (2016) Comparative performance evaluation of physicochemical treatment processes for simulated dairy wastewater. Int J Environ Sci Technol 13:1–14

Rodier J, Legube B, Marlet N et al (2009) Détermination de la DCO (méthode à reflux en système ouvert). In: DUNOD (ed) L’Analyse de l’Eau, vol 9. DUNOD, Paris, pp 987–991

Rombaut R, Dewettinck K (2007) Thermocalcic aggregation of milk fat globule membrane fragments from acid buttermilk cheese whey. J Dairy Sci 90:2665–2674

Ruchi S, Aradhana G, Kriti S (2013) Waste water management in dairy industry: pollution abatement and preventive attitudes. Paper presented at the Challenges & Opportunities for Technological Innovation in India (COTII), India

Rusten B, Lundar A, Eide O, Ødegaard H (1993) Chemical pretreatment of dairy wastewater. Water Sci Technol 28:67–76

Saffon M, Britten M, Pouliot Y (2011) Thermal aggregation of whey proteins in the presence of buttermilk concentrate. J Food Eng 103:244–250

Samaržija D, Antunac N, Havranek JL (2001) Taxonomy, physiology and growth of Lactococcus lactis: a review. Mljekarstvo 51:35–48

Seo YH, Park GW, Han JI (2015) Efficient lactulose production from cheese whey using sodium carbonate. Food Chem 173:1167–1171

Vidal G, Carvalho A, Méndez R, Lema JM (2000) Influence of the content in fats and proteins on the anaerobic biodegradability of dairy wastewaters. Bioresour Technol 74:231–239

Walstra P, Wouters JTM, Geurts TJ (1999) Dairy technology: principles of milk properties and processes, 2nd edn. CRC Press, Boca Ralton

Xiao Y, Wang L, Rui X, Li W, Chen X, Jiang M, Dong M (2015) Enhancement of the antioxidant capacity of soy whey by fermentation with Lactobacillus plantarum B1–6. J Fun Food 12:33–44

Zall R (1992) Sources and composition of whey and permeate. Elsevier, London

Acknowledgements

The first author acknowledges all the technical staff of the Tunisian dairy industry “La Centrale Laitière du Cap Bon” for their cooperation during the period of study and the sample withdrawals.

Author information

Authors and Affiliations

Corresponding author

Additional information

Editorial responsibility: Josef Trögl.

Rights and permissions

About this article

Cite this article

Kasmi, M., Djebali, K., Hamdi, M. et al. Physical–chemical treatment process optimization for high polluting dairy effluents prior fermentation. Int. J. Environ. Sci. Technol. 15, 779–790 (2018). https://doi.org/10.1007/s13762-017-1438-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13762-017-1438-4