Abstract

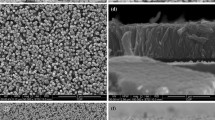

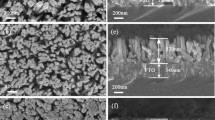

In this study, a facile, low cost, and scalable sol–gel method has been proposed for the coating of ultra-thin layer of TiO2 on FTO substrate as a seed layer for the growth of 3D-TiO2 nanorod (3D-TiO2-NR) arrays on FTO. Then, the two-step hydrothermal process including nanorod growth and the chemical etching treatment was proceeded for the fabrication of FTO/3D-TiO2-NR photoanodes. The thickness of the deposited TiO2 in FTO/TiO2-sg samples was measured with small-angle X-ray scattering technique, and it was obtained to be 21.3 nm. FE-SEM and TEM techniques were used for the morphological characterization of 3D-TiO2-NR, and it was obtained that the tightly adhered film of vertically aligned 3D-TiO2-NR with two-layer nanostructuring is formed with a cubic base and a nanorods head. Finally, DSSCs with iodine-based and cobalt(II/III) tris(2,2′-bipyridine) complex-based electrolytes with two different photoanodes including 3D-TiO2-NR and TiO2-NP were assembled and their photovoltaic characteristics were investigated. For [Co(bpy)3]2+/3+ shuttle-based DSSC, the obtained power conversion efficiency (η) was about 3.5% with Jsc of 9.36 mA cm−2 in 3D-TiO2-NR-based DSSC, while η of TiO2-NP-based DSSC was about 1.4%. The results showed that employing 3D-TiO2-NR-based photoanode in DSSCs with bulky electron shuttles remarkably improves the photovoltaic characteristics of DSSCs. Electrochemical impedance spectroscopic studies also showed the lower charge transfer resistances for DSSCs with nanorod-based photoanode building blocks.

Similar content being viewed by others

References

M. Abrari, M. Ahmadi, M. Ghanaatshoar, H.R. Moazami, S.S.H. Davarani, J. Alloys Compd. 784, 1036 (2019)

W. Liang, K. Fan, Y. Luan, Z. Tan, M. Al-Mamun, Y. Wang, P. Liu, H. Zhao, J. Alloys Compd. 772, 80 (2019)

Y. Rui, Y. Li, Q. Zhang, H. Wang, CrystEngComm 15, 1651 (2013)

G. Liu, J. Xu, K. Wang, Mater. Today Energy 10, 368 (2018)

O. Moradlou, Z. Rabiei, A. Banazadeh, J. Warzywoda, M. Zirak, Appl. Catal. B: Environ. 227, 178 (2018)

Z.J. Chermahini, A.N. Chermahini, H.A. Dabbagh, B. Rezaei, N. Irannejad, J. Iran. Chem. Soc. 14, 1549–1556 (2017)

A. Hagfeldt, G. Boschloo, L. Sun, L. Kloo, H. Pettersson, Chem. Rev. 110, 6595 (2010)

X.L. Zhang, W. Huang, A. Gu, W. Xiang, F. Huang, Z.X. Guo, Y.-B. Cheng, L. Spiccia, J. Mater. Chem. C 5, 4875 (2017)

P. Naik, R. Su, D.D. Babu, A. El-Shafei, A.V. Adhikari, J. Iran. Chem. Soc. 14, 2457–2466 (2017)

M.A. Hossain, S. Oh, S. Lim, J. Ind. Eng. Chem. 51, 122 (2017)

B. Wang, J. Wan, Q. Liu, J. Zhang, H. Wang, RSC Adv. 5, 82968 (2015)

K. Zhao, X. Zhang, M. Wang, W. Zhang, X. Li, H. Wang, L. Li, J. Alloys Compd. 786, 50–55 (2019)

H. Wang, B. Wang, J. Yu, Y. Hu, C. Xia, J. Zhang, R. Liu, Sci. Rep. 5, 9305 (2015)

Y.-Y. Li, J.-G. Wang, H.-H. Sun, B. Wei, ACS Appl. Mater. Interfaces 10, 11580 (2018)

T.S. Girisun, C. Jeganathan, N. Pavithra, S. Anandan, Nanotechnology 29, 085605 (2018)

L.-L. Li, C.-Y. Tsai, H.-P. Wu, C.-C. Chen, E.W.-G. Diau, J. Mater. Chem. 20, 2753 (2010)

B. Rezaei, I. Mohammadi, A.A. Ensafi, M.M. Momeni, Electrochim. Acta 247, 410 (2017)

Q. Sun, Y. Hong, T. Zang, Q. Liu, L. Yu, L. Dong, J. Electrochem. Soc. 165, H3069 (2018)

S. So, A. Kriesch, U. Peschel, P. Schmuki, J. Mater. Chem. A 3, 12603 (2015)

N. Naseri, M. Yousefi, O. Moradlou, A. Moshfegh, Phys. Chem. Chem. Phys. 13, 4239 (2011)

H. Wang, Y. Bai, H. Zhang, Z. Zhang, J. Li, L. Guo, J. Phys. Chem. C 114, 16451 (2010)

J. Wu, Z. Lan, J. Lin, M. Huang, Y. Huang, L. Fan, G. Luo, Chem. Rev. 115, 2136 (2015)

A. Colombo, C. Dragonetti, M. Magni, D. Roberto, F. Demartin, S. Caramori, C.A. Bignozzi, ACS Appl. Mater. Interfaces 6, 13945 (2014)

L. Xu, C. Xin, C. Li, W. Wu, J. Hua, W. Zhu, Sol. Energy 169, 450 (2018)

E.J. Crossland, N. Noel, V. Sivaram, T. Leijtens, J.A. Alexander-Webber, H.J. Snaith, Nature 495, 215 (2013)

C. Dong, W. Xiang, F. Huang, D. Fu, W. Huang, U. Bach, Y.-B. Cheng, X. Li, L. Spiccia, Nanoscale 6, 3704 (2014)

W. Yang, P. Yang, Q. Tang, Mater. Lett. 180, 228 (2016)

Acknowledgements

The authors would like to thank Research Council of Alzahra University for financial support (Grant No. 1397). A special thanks go to Dr. Simon Welzmiller and Dr. Sascha Correll (STOE Company, Germany) for their small-angle X-ray scattering (SAXS) measurements and valuable discussions.

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Khakpour, Z., Tavassoli, M. & Moradlou, O. Sol–gel approach for the growth of vertically aligned 3D-TiO2 nanorod arrays as an efficient photoanode for high-performance dye-sensitized solar cells. J IRAN CHEM SOC 17, 881–891 (2020). https://doi.org/10.1007/s13738-019-01821-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13738-019-01821-0