Abstract

In our previous work, it was found that there was a good correlation between the transfer film structure and wear rate of polytetrafluorethylene (PTFE) composites, and the transfer film presented a “terrace-like structure” under the influence of fillers. But whether that phenomenon was applicable to different fillers was not verified. In this work, the transfer film formed by silicon carbide (SiC)-filled PTFE was selected to study deeply. The results showed that the “terrace-like structure” was also formed by SiC/PTFE composite, where the number of transfer film layers was 2–3, and the thickness of each layer was about 0.1 μm. Such phenomenon was different compared with that of silicon dioxide (SiO2)/PTFE composite. By the segmented linear fitting between transfer film thickness and composite wear rate, we found that the effect of changes in transfer film thickness on the wear rate of composite can be divided into two stages: stable stage and promotion stage, and the correlation between maximum thickness and composite wear rate was enhanced. Similar phenomena were also reflected in the relationship between transfer film coverage and the wear rate of the SiC/PTFE composite. The maximum thickness and coverage of the transfer film had different effects on the wear rate of the composite at different stages. When the transfer film coverage was less than 24.8%, the change of the coverage rate of the transfer film showed a great impact on the wear rate of the composite. And when the transfer film maximum thickness was more than 0.342 μm, the change of the maximum thickness of the transfer film had a great impact on the wear rate of the composite.

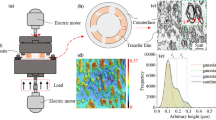

Graphical abstract

Similar content being viewed by others

Data availability

All data are included in this article.

References

Holmberg K, Erdemir A (2017) Influence of tribology on global energy consumption, costs and emissions. Friction 5:263–284

Farfan-Cabrera LI, Tapia-Gaspar M, Pérez-González J (2021) Tribology of polymer matrix composites within the automotive industry. Encyclopedia of materials: composites, vol 1. Elsevier, Amsterdam

Ren YL, Zhang L, Xie GX, Li ZB, Chen H, Gong HJ, Xu WH, Guo D, Luo JB (2021) A review on tribology of polymer composite coatings. Friction 9:429–470

Mao B, Siddaiah A, Liao YL, Menezes PL (2020) Laser surface texturing and related techniques for enhancing tribological performance of engineering materials: a review. J Manuf Process 53:153–173

Delprete C, Razavykia A (2018) Piston ring–liner lubrication and tribological performance evaluation: a review. Proc IME J J Eng Tribol 232:193–209

Dhanumalayan E, Joshi GM (2018) Performance properties and applications of polytetrafluoroethylene (PTFE): a review. Adv Compos Hybrid Mater 1:247–268

Sahin Y (2018) Dry wear and metallographic study of PTFE polymer composites. Mech Compos Mater 54:403–414

Manafi S, Kiahosseini SR (2020) Polytetrafluoroethylene/nanoclay composite as anti-wearing compound. Iran Polym J 29:25–35

Kececi E, Asmatulu R (2017) Effects of moisture ingressions on mechanical properties of honeycomb-structured fiber composites for aerospace applications. Int J Adv Manuf Technol 88:459–470

Gong DL, Xue QJ, Wang HL (1989) Study of the wear of filled polytetrafluoroethylene. Wear 134:283–295

Wang YX, Yan FY (2006) Tribological properties of transfer films of PTFE-based composites. Wear 261:1359–1366

Xie T, Zhou ZH, Xu ZX, Yu JW, Jiao MH (2013) Characteristics of the transfer film and tribological properties of oxide/PTFE composites. Adv Mater Res 631:172–175

Tanaka K, Kawakami S (1982) Effect of various fillers on the friction and wear of polytetrafluoroethylene-based composites. Wear 79:221–234

Bahadur S, Tabor D (1984) The wear of filled polytetrafluoroethylene. Wear 98:1–13

Lancaster JK (1968) The effect of carbon fibre reinforcement on the friction and wear of polymers. J Phys D Appl Phys 1:549–559

Blanchet TA (1995) A model for polymer composite wear behavior including preferential load support and surface accumulation of filler particulates. Tribol Trans 38:821–828

Blanchet TA, Kennedy FE (1992) Sliding wear mechanism of polytetrafluoroethylene (PTFE) and PTFE composites. Wear 153:229–243

Xie T, Xu ZX, Yan ZM, Chen G, Jiao MH, Yu JW, Yin YG (2011) Study on the friction and wear behaviors of Cu/PTFE self-lubricating composites. Appl Mech Mater 130:1466–1469

Wang ZQ, Wu SF, Ni J (2018) Influence of SiO2/MoS2/graphite content on the wear properties of PTFE composites under natural seawater lubrication. Proc IME J J Eng Tribol 232:607–618

Burris DL, Sawyer WG (2006) A low friction and ultra low wear rate PEEK/PTFE composite. Wear 261:410–418

Zhang Z-Z, Liu W-M, Xue Q-J (2001) Effects of various kinds of fillers on the tribological behavior of polytetrafluoroethylene composites under dry and oil-lubricated conditions. J Appl Polym Sci 80:1891–1897

Ye JX, Khare HS, Burris DL (2014) Quantitative characterization of solid lubricant transfer film quality. Wear 316:133–143

Zhang LX, Xie T, Chen K, Li WB (2022) Observation and analysis of the terrace-like structured transfer film of SiO2/PTFE composites. Tribol Int 170:107526

Zhang LX, Xie T, Chen K, Li C, Wen H, Shi YR, Zhang JL (2021) Quantitative characterization of the transfer film morphology of SiO2/PTFE composite. Wear 484:204047

Wang A, Lin B, Zou H, Wei C, Meng Y, Sui T, Yan S (2020) Effect of micrometer sized ceramic particles on the tribological properties of polytetrafluoroethylene based composites. Surf Topogr Metrol Prop 8:035005

Zhao ZH, Chen JN (2011) Preparation of single-polytetrafluoroethylene composites by the processes of compression molding and free sintering. Compos Part B Eng 42:1306–1310

Li XL, Wu S, Ling YL, Zhang CH, Luo JB, Dai YJ (2020) Preparation and tribological properties of PTFE/DE/ATF6 composites with self-contained solid-liquid synergetic lubricating performance. Compos Commun 22:100513

Haidar DR, Ye J, Moore AC, Burris DL (2017) Assessing quantitative metrics of transfer film quality as indicators of polymer wear performance. Wear 380:78–85

Laux KA, Schwartz CJ (2013) Influence of linear reciprocating and multi-directional sliding on PEEK wear performance and transfer film formation. Wear 301:727–734

Ye J, Burris DL, Xie T (2016) A review of transfer films and their role in ultra-low-wear sliding of polymers. Lubricants. https://doi.org/10.3390/lubricants4010004

Khedkar J, Negulescu I, Meletis EI (2002) Sliding wear behavior of PTFE composites. Wear 252:361–369

Ye J, Khare HS, Burris DL (2013) Transfer film evolution and its role in promoting ultra-low wear of a PTFE nanocomposite. Wear 297:1095–1102

Acknowledgements

This work was supported by the National Natural Science Foundation of China (grant number 51275144).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Li, W., Zhang, L. & Xie, T. Effect of transfer film morphology on the wear rate of SiC/PTFE composite. Iran Polym J 32, 1123–1133 (2023). https://doi.org/10.1007/s13726-023-01185-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13726-023-01185-6