Abstract

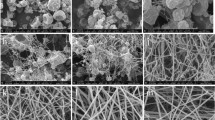

The production of rocket seed mucilage (RSM)/polyvinyl alcohol (PVA) nanofibers has been carried out by electrospinning method followed by their characterization. In this study, 1% RSM and 10% PVA were used for nanofiber production. The determined RSM/PVA ratio was 60:40. The morphology of nanofibers was studied using scanning electron microscopy (SEM). In addition, Fourier transform infrared spectrometry (FTIR) and X-ray diffractometry (XRD) analyses were used to determine the crystal structure of the chemical composition. According to SEM images, beadless, uniform, and smooth nanofibers were produced. The mean diameter of the nanofibers was 102.3 nm. The diffractogram of RSM/PVA nanofibers was similar to RSM diffractogram, namely two slight crystalline peaks at about 2θ ≈ 14.19° and 26.62°. A broad peak was obtained at 2θ ≈ 21.21°. This result shows that the nanofiber has some degree of amorphous structure, revealing that the crystalline structure of PVA is decomposed during electrospinning. There was no chemical interaction between RSM and PVA when producing RSM/PVA nanofibers, and PVA improved the physical properties of RSM. In conclusion, this research is the first study on nanofiber production with rocket seed mucilage and PVA. The produced nanofibers can be used in food and pharmaceutical industry, and in the encapsulating bioactive compounds. These nanofibers are more advantageous in biosafety, biocompatibility, and biodegradability compared to synthetic materials.

Graphical Abstract

Similar content being viewed by others

Data availability

Data from this study are available to the journal. For other data sets, the corresponding author should be contacted.

References

Okutan N, Terzi P, Altay F (2014) Affecting parameters on electrospinning process and characterization of electrospun gelatin nanofibers. Food Hydrocoll 39:19–26. https://doi.org/10.1016/j.foodhyd.2013.12.022

Alghoraibi I, Alomari S (2018) Different methods for nanofiber design and fabrication. In: Barhoum A, Bechelany M, Hamdy Makhlouf AS (eds) Handbook of nanofibers. Springer, Cham, pp 1–46

Almetwally AA, El-Sakhawy M, Elshakankery MH, Kasem MH (2017) The technology of nanofibers: production techniques and properties-critical review. J Text Assoc 78:5–14

Fathi M (2015) Nano-Delivery system for development of functional food: production, application and trends. In: Govil GN (ed) Nutraceuticals and functional food. Studium Press, New Delhi, India, pp 270–288

Bhardwaj N, Kundu SC (2010) Electrospinning: a fascinating fiber fabrication technique. Biotechnol Adv 28:325–347. https://doi.org/10.1016/j.biotechadv.2010.01.004

Das A, Balakrishnan N, Joyner JD, Medhavi N, Manaf O, Jabeen Fatima MJ, Prasanth R (2021) Electrospinning: the state of the art technique for producing nanofibers and nanofibrous membranes for advanced engineering applications. Electrospin Adv Energy Storage Appl 2021:23–71

Garg K, Bowlin GL (2011) Electrospinning jets and nanofibrous structures. Biomicrofluidics 5:013403. https://doi.org/10.1063/1.3567097

https://www.researchgate.net/figure/Schematic-view-of-electrospinningprocess_fig9_305662363

Garg G, Sharma V (2014) Eruca sativa (L.): botanical description, crop improvement, and medicinal properties. J Herbs Spices Med Plants 20:171–182. https://doi.org/10.1080/10496475.2013.848254

Koocheki A, Razavi SMA, Hesarinejad MA (2012) Effect of extraction procedures on functional properties of Erucasativa seed mucilage. Food Biophys 7:84–92. https://doi.org/10.1007/s11483-011-9245-9

Gulfraz M, Sadiq A, Tariq H, Imran M, Qureshi R, Zeenat A (2011) Phytochemical analysis and antibacterial activity of Eruca sativa seed. Pak J Bot 43:1351–1359

Barillari J, Canistro D, Paolini M, Ferroni F, Pedulli GF, Iori R, Valgimigli L (2005) Direct antioxidant activity of purified glucoerucin, the dietary secondary metabolite contained in rocket (Eruca sativa Mill.) seeds and sprouts. J Agric Food Chem 53:2475–2482. https://doi.org/10.1021/jf047945a

Melchini A, Costa C, Traka N, Miceli N, Mithen R, Pasquale RD, Trovato A (2009) Erucin, a new promising cancer chemopreventive agent from rocket salads, shows anti-proliferative activity on human lung carcinoma A549 cells. Food Chem Toxicol 47:1430–1436. https://doi.org/10.1016/j.fct.2009.03.024

El-Missiry MA, Am EG (2000) Amelioration of alloxan induced diabetes mellitus and oxidative stress in rats by oil of Eruca sativa seeds. Ann Nutr Metab 44:97–100. https://doi.org/10.1159/000012829

Alqasoumi S, Al-Sohaibani M, Al-Howiriny T, Al-Yahya M, Rafatullah S (2009) Rocket “Eruca sativa”: a salad herb with potential gastric anti-ulcer activity. World J Gastroenterol 15:1958–1965. https://doi.org/10.3748/wjg.15.1958

Abd-Elsalam RM, El Badawy SA, Ogaly HA, Ibrahim FM, Farag OM, Ahmed KA (2021) Eruca sativa seed extract modulates oxidative stress and apoptosis and up-regulates the expression of Bcl-2 and Bax genes in acrylamide-induced testicular dysfunction in rats. Environ Sci Pollut Res 28:53249–53266. https://doi.org/10.1007/s11356-021-14532-y

Khan MAJ, Khan RJ (1985) Insecticidal effects of indigenous vegetable oils (taramira and artemisia) on some rice delphacids in Pakistan. Pak J Sci Ind Res 28:428–429

Narang DD, Atwal AS (1989) Effect of leaf extracts containing glucosinolates on the biology of mustard aphid, Lipaphis erysimi (Kalt.). Ind J Ecol 13:307–312

Kutlu G, Akcicek A, Bozkurt F, Karasu S, Tekin-Cakmak ZH (2021) Rocket seed (Eruca sativa Mill) gum: physicochemical and comprehensive rheological characterization. Food Sci Technol 2021:42. https://doi.org/10.1590/fst.69620

Golkar P, Kalani S, Allafchian AR, Mohammadi H, Jalali SAH (2019) Fabrication and characterization of electrospun Plantago major seed mucilage/PVA nanofibers. J Appl Polym Sci 136:47852. https://doi.org/10.1002/APP.47852

Gaaz T, Sulong A, Akhtar M, Kadhum A, Mohamad A, Al-Amiery A (2015) Properties and applications of polyvinyl alcohol, halloysite nanotubes and their nanocomposites. Molecules 20:22833–22847. https://doi.org/10.3390/molecules201219884

Kurd F, Fathi M, Shekarchizadeh H (2017) Basil seed mucilage as a new source for electrospinning: production and physicochemical characterization. Int J Biol Macromol 95:689–695. https://doi.org/10.1016/j.ijbiomac.2016.11.116

Fahami A, Fathi M (2018) Development of cress seed mucilage/PVA nanofibers as a novel carrier for vitamin A delivery. Food Hydrocoll 81:31–38. https://doi.org/10.1016/j.foodhyd.2018.02.008

Turan K, Akcan M, Kalfa OM (2021) Preparation characterization and antibacterial activity of Malva Sylvestris L. seed extract containing novel electrospun PVA nanofibers. Gazi Univ J Sci 34:987–998

Tekin MD, Kalfa OM (2022) Preconcentration of some heavy metals with novel electrospun nanofiber including Quince seed mucilage. Water Air Soil Pollut 233:1–14. https://doi.org/10.1007/s11270-022-05680-z

Tian D, Yu DN, Xu YM, Ding XY, Zhang ZY, Wan CL, He JH (2020) Electrospun mussel-derived silk fibers. Recent Patents Nanotechnol 14:14–20. https://doi.org/10.2174/1872210513666190426145024

Zhou CJ, Li Y, Yao SW, He JH (2019) Silkworm-based silk fibers by electrospinning. Results Phys 15:102646. https://doi.org/10.1016/j.rinp.2019.102646

Zhou CJ, Chen C, Zhou HY, He JH (2019) Fabrication of latex-based nanofibers by electrospinning. Recent Patent Nanotechnol 13:202–205. https://doi.org/10.2174/1872210513666190925160735

Yu DN, Tian D, Zhou CJ, He JH (2019) Wetting and supercontraction properties of spider-based nanofibers. Therm Sci 23:2189–2193. https://doi.org/10.2298/TSCI1904189Y

Yu DN, Tian D, He JH (2018) Snail-based nanofibers. Mater Lett 220:5–7. https://doi.org/10.1016/j.matlet.2018.02.076

Karazhiyan H (2008) Extraction optimization and physical properties of cress seed hydrocolloid using response surface methodology. Doctoral dissertation, PhD thesis, Ferdowsi University of Mashhad, Iran

Jafari SM, Mahdavi-Khazaei K, Hemmati-Kakhki A (2016) Microencapsulation of saffron petal anthocyanins with cress seed gum compared with Arabic gum through freeze drying. Carbohydr Polym 140:20–25. https://doi.org/10.1016/j.carbpol.2015.11.079

Santos C, Silva CJ, Büttel Z, Guimarães R, Pereira SB, Tamagnini P, Zille A (2014) Preparation and characterization of polysaccharides/PVA blend nanofibrous membranes by electrospinning method. Carbohydr Polym 99:584–592. https://doi.org/10.1016/j.carbpol.2013.09.008

Hadad S, Goli SAH (2018) Fabrication and characterization of electrospun nanofibers using flaxseed (Linum usitatissimum) mucilage. Int J Biol Macromol 114:408–414. https://doi.org/10.1016/j.ijbiomac.2018.03.154

Taheri A, Razavi SMA (2015) Fabrication of cress seed gum nanoparticles, an anionic polysaccharide, using desolvation technique: an optimization study. Bio Nano Sci 5:104–116. https://doi.org/10.1007/s12668-015-0169-6

Akcicek A, Bozkurt F, Akgül C, Karasu S (2021) Encapsulation of olive pomace extract in rocket seed gum and chia seed gum nanoparticles: characterization, antioxidant activity and oxidative stability. Foods 10:1735. https://doi.org/10.3390/foods10081735

Allafchian AR, Kalani S, Golkar P, Mohammadi H, Jalali SAH (2020) A comprehensive study on Plantago ovata/PVA biocompatible nanofibers: fabrication, characterization, and biological assessment. J Appl Polym Sci 137:49560. https://doi.org/10.1002/app.49560

Islam MS, Rahaman MS, Yeum JH (2015) Electrospun novel super-absorbent based on polysaccharide-polyvinyl alcohol-montmorillonite clay nanocomposites. Carbohydr Polym 115:69–77. https://doi.org/10.1016/j.carbpol.2014.08.086

Motamedi AS, Mirzadeh H, Hajiesmaeilbaigi F, Bagheri-Khoulenjani S, Shokrgozar MA (2017) Effect of electrospinning parameters on morphological properties of PVDF nanofibrous scaffolds. Prog Biomat 6:113–123. https://doi.org/10.1007/s40204-017-0071-0

Abd El-aziz AM, El-Maghraby A, Taha NA (2016) Comparison between polyvinyl alcohol (PVA) nanofiber and polyvinyl alcohol (PVA) nanofiber/hydroxyapatite (HA) for removal of Zn2+ ions from waste water. Arab J Chem 10:1052–1060. https://doi.org/10.1016/j.arabjc.2016.09.025

Ullah S, Hashmi M, Hussain N, Ullah A, Sarwar MN, Saito Y, Kim SH, Kim IS (2020) Stabilized nanofibers of polyvinyl alcohol (PVA) crosslinked by unique method for efficient removal of heavy metal ions. J Water Process Eng 33:101111. https://doi.org/10.1016/j.jwpe.2019.101111

Thompson CJ, Chase GG, Yarin AL, Reneker DH (2007) Effects of parameters on nanofiber diameter determined from electrospinning model. Polymer 48:6913–6922. https://doi.org/10.1016/j.polymer.2007.09.017

Haider A, Haider S, Kang IK (2018) A comprehensive review summarizing the effect of electrospinning parameters and potential applications of nanofibers in biomedical and biotechnology. Arab J Chem 11:1165–1188. https://doi.org/10.1016/j.arabjc.2015.11.015

Priya S, Batra U, Samshritha RN, Sharma S, Chaurasiya A, Singhvi G (2022) Polysaccharide-based nanofibers for pharmaceutical and biomedical applications: a review. Int J Biol Macromol 218:209–224. https://doi.org/10.1016/j.ijbiomac.2022.07.118

Sherahi M, Fathi M, Zhandari F, Hashemi SMB, Rashidi A (2017) Structural characterization and physicochemical properties of Descurainia sophia seed gum. Food Hydrocoll 66:82–89. https://doi.org/10.1016/j.foodhyd.2016.12.010

Kačuráková M, Belton PS, Wilson RH, Hirsch J, Ebringerová A (1998) Hydration properties of xylan-type structures: an FTIR study of xylooligosaccharides. J Sci Food Agric 77:38–44. https://doi.org/10.1002/(SICI)1097-0010(199805)77:1%3c38::AID-JSFA999%3e3.0.CO;2-5

Park J, Lee HW, Chae DK, Oh W, Yun JD, Deng Y, Yeum JH (2009) Electrospinning and characterization of poly (vinyl alcohol)/chitosan oligosaccharide/clay nanocomposite nanofibers in aqueous solutions. Colloid Polym Sci 287:943–950. https://doi.org/10.1007/s00396-009-2050-z

Rezaei A, Tavanai H, Nasirpour A (2016) Fabrication of electrospun almond gum/PVA nanofibers as a thermostable delivery system for vanillin. Int J Biol Macromol 91:536–543. https://doi.org/10.1016/j.ijbiomac.2016.06.005

Yang R, He J, Xu L, Yu J (2009) Bubble-electrospinning for fabricating nanofibers. Polymer 50:5846–5850. https://doi.org/10.1016/j.polymer.2009.10.021

Funding

No funding was received.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors report no conflicts of interest.

Research ınvolving humans and animals statement

This study does not include animal or human experimentation.

Informed consent

Informed consent is not required as no animal or human subjects were used in this study.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Tekin, M.D., Çelikozlu, S. & Aydin, H. Electrospun rocket seed (Eruca sativa Mill) mucilage/polyvinyl alcohol nanofibers: fabrication and characterization. Iran Polym J 32, 203–211 (2023). https://doi.org/10.1007/s13726-022-01117-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13726-022-01117-w