Abstract

High-density polyethylene (HDPE) composites were reinforced with artichoke leaf powder (ALP) at different concentrations of 0%–30% (by weights). Fourier transform infrared spectroscopy (FTIR) was used to observe the chemical bonds of these materials. In addition, scanning electron microscopy (SEM) was examined to evaluate the microstructure of artichoke leaf particles and the effect of ALP addition on compatibility. The results of dynamic mechanical analysis (DMA) and thermogravimetric differential thermal analysis (TG/DTA) showed that the addition of ALP provided enhanced viscoelastic and thermal properties. In the X-ray diffraction (XRD) results, ALP addition to HDPE caused peaks to shift and their intensity decreased with increasing ALP concentration. Melting and crystallization temperatures of the samples were obtained by differential scanning calorimetry (DSC) analysis. Moreover, tensile properties including elasticity modulus, tensile strength-at-break, yield strength and elongation percentage were evaluated. The results of the tensile tests revealed that tensile strength-at-break and elasticity modulus of ALP-reinforced HDPE composites enhanced with increasing ALP loading. On the other hand, elongation-at-break percentage decreased sharply with increasing ALP weight fraction. This study has shown that the composites reinforced with ALP as natural fillers could be regarded as a promising alternative among wood plastic composites (WPCs).

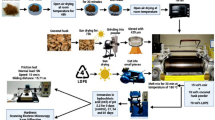

Graphical abstract

Similar content being viewed by others

References

Ashori A, Nourbakhsh A (2010) Bio-based composites from waste agricultural residues. Waste Manag 30:680–684. https://doi.org/10.1016/j.wasman.2009.08.003

Lau K, Hung P, Zhu MH, Hui D (2018) Properties of natural fibre composites for structural engineering applications. Compos B 136:222–233. https://doi.org/10.1016/j.compositesb.2017.10.038

Dawit JB, Regassa Y, Lemu HG (2020) Property characterization of acacia tortilis for natural fiber reinforced polymer composite. Results Mater 5:100054. https://doi.org/10.1016/j.rinma.2019.100054

Barczewski M, Mysiukiewicz O, Kloziński A (2018) Complex modification effect of linseed cake as an agricultural waste filler used in high density polyethylene composites. Iran Polym J 27:677–688. https://doi.org/10.1007/S13726-018-0644-3

Yusoff RB, Takagi H, Nakagaito AN (2016) Tensile and flexural properties of polylactic acid-based hybrid green composites reinforced by kenaf, bamboo and coir fibers. Ind Crops Prod 94:562–573. https://doi.org/10.1016/j.indcrop.2016.09.017

Dar RA, Parmar M, Dar EA, Sani RK, Phutela UG (2021) Biomethanation of agricultural residues: potential, limitations and possible solutions. Renew Sustain Energy Rev 135:110217

Amir N, Abidin KAZ, Shiri FBM (2017) Effects of fibre configuration on mechanical properties of banana fibre/PP/MAPP natural fibre reinforced polymer composite. Proc Eng 184:573–580 https://doi.org/10.1016/j.proeng.2017.04.140

Kumar R, Haq UI, MI, Raina A, Anand A, (2019) Industrial applications of natural fibre-reinforced polymer composites-challenges and opportunities. Int J Sustain Eng 12:212–220

Binoj JS, Raj RE, Indran S (2018) Characterization of industrial discarded fruit wastes (Tamarindus Indica L.) as potential alternate for man-made vitreous fiber in polymer composites. Process Saf Environ Prot 116:527–534. https://doi.org/10.1016/j.psep.2018.02.019

Asim M, Paridah MT, Chandrasekar M, Shahroze Rao M, Jawaid M, Nasir M, Siakeng R (2020) Thermal stability of natural fibers and their polymer composites. Iran Polym J 29:625–648. https://doi.org/10.1007/S13726-020-00824-6

De Rosa IM, Kenny JM, Puglia D, Santulli C, Sarasini F (2010) Tensile behavior of New Zealand flax (Phormium tenax) fibers. J Reinf Plast Compos 29:3450–3454. https://doi.org/10.1177/0731684410372264

Chandrasekar M, Ishak MR, Sapuan SM, Leman Z, Jawaid M (2017) A review on the characterisation of natural fibres and their composites after alkali treatment and water absorption. Plast Rubber Compos 46:119–136. https://doi.org/10.1080/14658011.2017.1298550

Dixit S, Goel R, Dubey A, Shivhare PR, Bhalavi T (2017) Natural fibre reinforced polymer composite materials: a review. PolymRenew Resour 8:71–78 10.1177%2F204124791700800203

Fiore V, Valenza A, Di Bella G (2011) Artichoke (Cynara cardunculus L.) fibres as potential reinforcement of composite structures. Compos Sci Technol 71:1138–1144. https://doi.org/10.1016/j.compscitech.2011.04.003

Olcay H, Kocak ED (2020) The mechanical, thermal and sound absorption properties of flexible polyurethane foam composites reinforced with artichoke stem waste fibers. J Ind Text 152808372093419 DOI: https://doi.org/10.1177/1528083720934193

Bencheikh I, Azoulay K, Mabrouki J, Hajjaji SEl, Dahchour A, Moufti A, Dhiba D (2020) The adsorptive removal of MB using chemically treated artichoke leaves: parametric, kinetic, isotherm and thermodynamic study. Sci African 9:e00509 Doi: https://doi.org/10.1016/j.sciaf.2020.e00509

Pesce GR, Fernandes MC, Mauromicale G (2020) Globe artichoke crop residues and their potential for bioethanol production by dilute acid hydrolysis. Biomass and Bioenergy 134:105471 https://doi.org/10.1016/j.biombioe.2020.105471

Gumu BE, Yagci O, Erdogan DC, Tademir M (2019) Dynamical mechanical properties of polypropylene composites filled with olive pit particles. J Test Eval 47:2551–2561. https://doi.org/10.1520/JTE20180198

Prusty K, Barik S, Swain SK (2019) A corelation between the graphene surface area, functional groups, defects, and porosity on the performance of the nanocomposites. Funct Graphene Nanocompos Their Deriv 2019:265–283 https://doi.org/10.1016/B978-0-12-814548-7.00013-1

Matuana LM, Jin S, Stark NM (2011) Ultraviolet weathering of HDPE/wood-flour composites coextruded with a clear HDPE cap layer. Polym Degrad Stab 96:97–106. https://doi.org/10.1016/j.polymdegradstab.2010.10.003

Fernández-López JA, Angosto JM, Roca MJ, Doval Miñarro M (2019) Taguchi design-based enhancement of heavy metals bioremoval by agroindustrial waste biomass from artichoke. Sci Total Environ 653:55–63. https://doi.org/10.1016/j.scitotenv.2018.10.343

Benabid F, Kharchi N, Zouai F, Mourad AHI, Benachour D (2019) Impact of co-mixing technique and surface modification of ZnO nanoparticles using stearic acid on their dispersion into HDPE to produce HDPE/ZnO nanocomposites. Polym Polym Compos 27:389–399. https://doi.org/10.1177/0967391119847353

Miao W, Zhu H, Duan T, Chen Hongbing, WU F, Jiang L, Wang Z (2018) High-density polyethylene crystals with double melting peaks induced by ultra-high-molecular-weight polyethylene fibre. Royal Soc Open Sci 5:180394 https://doi.org/10.1098/RSOS.180394

Yağci Ö, Eker Gümüş B, Taşdemir M (2020) Thermal, structural and dynamical mechanical properties of hollow glass sphere-reinforced polypropylene composites. Polym Bull 78:3089–3101. https://doi.org/10.1007/s00289-020-03257-6

Abdan KB, Yong SC, Chiang ECW, Talib RA, Hui TC, Hao LC (2020) Barrier properties, antimicrobial and antifungal activities of chitin and chitosan-based IPNs, gels, blends, composites, and nanocomposites. Handb Chitin Chitosan 2020:175–227. https://doi.org/10.1016/B978-0-12-817968-0.00006-8

Irwanto D, Pidhatika B, Nurhajati DW, Harjanto S (2020) Mechanical properties and crystallinity of linear low density polyethylene based biocomposite film. Maj Kulit Karet dan Plast 35:93 https://doi.org/10.20543/MKKP.V35I2.5624

Li D, Zhou L, Wang X, He L, Yang X (2019) Effect of crystallinity of polyethylene with different densities on breakdown strength and conductance property. Materials 12:1746 https://doi.org/10.3390/MA12111746

Dyamenahalli K, Famili A, Shandas R (2015) Characterization of shape-memory polymers for biomedical applications. Shape Mem Polym Biomed Appl 2015:35–63. https://doi.org/10.1016/B978-0-85709-698-2.00003-9

Gu B, Burgess DJ (2014) Polymeric materials in drug delivery. Nat Synth Biomed Polym 2014:333–349. https://doi.org/10.1016/B978-0-12-396983-5.00021-1

Molefi JA, Luyt AS, Krupa I (2010) Comparison of the influence of copper micro- and nano-particles on the mechanical properties of polyethylene/copper composites. J Mater Sci 45:82–88. https://doi.org/10.1007/s10853-009-3894-9

Sewda K, Maiti SN (2013) Dynamic mechanical properties of high density polyethylene and teak wood flour composites. Polym Bull 70:2657–2674. https://doi.org/10.1007/s00289-013-0941-0

Kord B, Ravanfar P, Ayrilmis N (2017) Influence of organically modified nanoclay on thermal and combustion properties of bagasse reinforced HDPE nanocomposites. J Polym Environ 25:1198–1207. https://doi.org/10.1007/s10924-016-0897-x

Schick C (2009) Differential scanning calorimetry (DSC) of semicrystalline polymers. Anal Bioanal Chem 395:1589–1611. https://doi.org/10.1007/S00216-009-3169-Y

Al Ashraf A (2015) Thermal analysis of polymers (LDPE, HDPE) by differential scanning calorimetry technique. An Open Forum for Expert Opinions and Discussion View Project https://doi.org/10.13140/2.1.1558.0963

Alothman OY (2012) Processing and characterization of high density polyethylene/ethylene vinyl acetate blends with different VA contents. Adv Mater Sci Eng 2012:ID 635693 https://doi.org/10.1155/2012/635693

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Gümüş, B.E., Yağci, Ö. & Taşdemir, M. High-density polyethylene/artichoke leaf powder polymer composites: dynamic mechanical, morphological and thermal properties. Iran Polym J 31, 787–797 (2022). https://doi.org/10.1007/s13726-022-01031-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13726-022-01031-1