Abstract

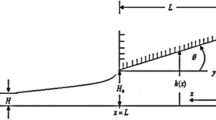

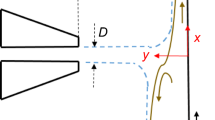

The coating process is significant in terms of its practical applications in the field of paint and electronics industries. The coating process offers a protective layer in paints; however, it stores information in electronics industries. Current study gives insight on the blade coating analysis by passing an upper convected Jeffery’s material through the narrow gap between the moving substrate and a fixed blade. The basic flow expressions were simplified by utilizing lubrication approximation theory, and then solved using the perturbation analysis and numerical shooting technique. The study discussed the effects of material parameters in both cases of plane and exponential coaters. The variations of Weissenberg number, viscosities ratio and normalized coating thickness on the maximum pressure, pressure gradient, coating thickness, pressure, and load are presented through graphs and in a tabular manner. In addition, the perturbation results were validated by comparing with the numerical outcomes and found an excellent agreement. It is noted that increasing both the Weissenberg number and viscosities ratio resulted in reduced coating thickness and increased blade load, hence were the controlling parameters, as they certified the coating quality and life of the substrate. Besides, the parameters had significant impacts on the velocity and pressure profiles. In addition, maximum pressure was directly proportional to the Weissenberg number and viscosities ratio.

Graphical abstract

Similar content being viewed by others

References

Ruschak KJ (1985) Coating flows. Ann Rev Fluid Mech 17:65–89

Middleman S (1977) Fundamentals of polymer processing. Mcgraw-Hill College, New York

Greener Y, Middleman S (1974) Blade coating of a viscoelastic fluid. Polym Eng Sci 14:791–796

Hwang SS (1982) Non-Newtonian liquid blade coating process. Trans ASME J Fluids Eng 104:469–475

Ross AB, Wilson SK, Duffy BR (1999) Blade coating of a power law fluid. Phys Fluids 11:958–970

Penterman R, Klink SI, De Koning H, Nisato G, Broer DJ (2002) Single-substrate liquid-crystal displays by photo-enforced stratification. Nature 417:55–58

Quintans JC, Mottram NJ, Wilson SK, Duffy BR (2007) A mathematical model for blade coating of a nematic liquid crystal. Liq Cryst 34:621–631

Giacomin AJ, Cook JD, Johnson LM, Mix AW (2012) Flexible blade coating. J Coat Technol Res 9:269–277

Willinger B, Delgado A (2014) Analytical prediction of roll coating with counter-rotating deformable rolls. J Coat Technol Res 11:31–37

Siddiqui AM, Bhatti S, Rana MA, Zahid M (2014) Blade coating analysis of a Williamson fluid. Results Phy 7:2845–2850

Rana MA, Siddiqui AM, Bhatti S, Zahid M (2018) The study of the blade coating process lubricated with Powell-Eyring Fluid. J Nanofluids 7:52–61

Ali N, Atif HM, Javed MA, Sajid MA (2018) Theoretical analysis of roll-over-web coating of couple stress fluid. J Plastic Film Sheet 34:43–59

Atif HM, Ali N, Javed MA, Abbas F (2018) Theoretical analysis of roll-over-web coating of a micropolar fluid under lubrication approximation theory. J Plast Film Sheet 34:418–438

Sajid M, Mughees M, Ali N, Shahzad H (2019) A theoretical analysis of blade coating for third-grade fluid. J Plast Film Sheet 35:218–238

Sajid M, Shahzad H, Mughees M, Ali N (2019) Mathematical modeling of slip and magnetohydrodynamics effects in blade coating. J Plast Film Sheet 35:9–21

Ershad-Langroudi A, Rahimi A (2014) Effect of ceria and zirconia nanoparticles on corrosion protection and viscoelastic behavior of hybrid coatings. Iran Polym J 23:267–276

Sugumaran S, Bellan CS, Nadimuthu M (2015) Characterization of composite PVA–Al2O3 thin films prepared by dip coating method. Iran Polym J 24:63–74

Mirmohseni A, Gharieh A, Khorasani M (2016) Waterborne acrylic–polyaniline nanocomposite as antistatic coating: preparation and characterization. Iran Polym J 25:991–998

Nal P, Mestry S, Mapari S, Mhaske S (2019) Eugenol/vanillin-derived novel triarylmethane-based crosslinking agent for epoxy coating Iran. Polym J 28:685–695

Zheng G, Wachter F, Al-Zoubi A, Durst F, Taemmerich R, Stietenroth M, Pircher P (2020) Computations of coating windows for reverse roll coating of liquid films. J Coat Technol Res 17:897–910

Shahzad H, Wang X, Mughees M, Sajid M, Ali N (2019) A mathematical analysis for the blade coating process of Oldroyd 4-constant fluid. J Polym Eng 39:852–860

Wang X, Shahzad H, Chen Y, Kanwal M, Ullah Z (2020) Mathematical modelling for flexible blade coater with magnetohydrodynamic and slip effects in blade coating process. J Plast Film Sheet 36:38–54

Khaliq S, Abbas Z (2020) A theoretical analysis of roll-over-web coating assessment of viscous nanofluid containing Cu-water nanoparticles. J Plast Film Sheet 36:55–75

Kanwal M, Wang X, Shahzad H, Chen Y, Chai H (2020) Blade coating analysis of viscous nanofluid having Cu–water nanoparticles using flexible blade coater. J Plast Film Sheet 36:348–367

Abbas Z, Khaliq S (2021) Calendering analysis of non-isothermal viscous nanofluid containing Cu-water nanoparticles using two counter-rotating rolls. J Plast Film Sheet 37:182–220

Khaliq S, Abbas Z (2021) Theoretical analysis of blade coating process using simplified Phan-Thien-Tanner fluid model: an analytical study. Polym Eng Sci 61:301–313

Zahid M, Khan NZ, Siddiqui AM, Iqbal S, Muhammad A, Tlili I (2021) Analysis of the lubrication approximation theory in the calendering/sheeting process of upper convected Jeffery’s material. J Plast Film Sheet 37:128–159

Khaliq S, Abbas Z (2021) Non-isothermal blade coating analysis of viscous fluid with temperature-dependent viscosity using lubrication approximation theory. J Polym Eng 41:705–716. https://doi.org/10.1515/polyeng-2021-0087

Mughees M, Sajid M, Shahzad H, Sadiq MN, Ali N (2021) An exact solution for blade coating of a second-grade fluid on a porous substrate. J Plast Film Sheet. https://doi.org/10.1177/87560879211035429

Azam M, Xu T, Khan M (2020) Numerical simulation for variable thermal properties and heat source/sink in flow of Cross nanofluid over a moving cylinder. Int Comm Heat Mass Transf 118:104832

Azam M, Xu T, Shakoor A, Khan M (2020) Effects of Arrhenius activation energy in development of covalent bonding in axisymmetric flow of radiative-cross nanofluid. Int Comm Heat Mass Transf 113:104547

Rajagopal KR, Bhatnagar RK (1995) Exact solutions for some simple flows of an Oldroyd-B fluid. Acta Mech 113:233–239

Hayat T, Siddiqui AM, Asghar S (2001) Some simple flows of an Oldroyd-B fluid. Int J Eng Sci 39:135–147

Brandi AC, Mendoça MT, Souza LF (2019) DNS and LST stability analysis of Oldroyd-B fluid in a flow between two parallel plates. J Non-Newton Fluid Mech 267:14–27

Abbas Z, Rafiq MY, Hasnian J, Umer H (2021) Impacts of lorentz force and chemical reaction on peristaltic transport of Jeffrey fluid in a penetrable channel with injection/suction at walls. Alex Eng J 60:1113–1122

Hayat T, Kiyani MZ, Ahmad I, Alsaedi A (2019) Double stratified radiative flow of an Oldroyd-B nanofluid with nonlinear convection. Appl Math Mech 40:1861–1878

Author information

Authors and Affiliations

Corresponding author

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Abbas, Z., Khaliq, S. Variation of coating thickness in blade coating process of an upper-convected Jeffery’s fluid model. Iran Polym J 31, 343–355 (2022). https://doi.org/10.1007/s13726-021-01002-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13726-021-01002-y