Abstract

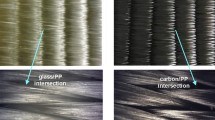

Tensile strength and impact toughness of inter-layer hybrid composites, made of twill woven E-glass fabric and unidirectional carbon fiber in epoxy resin matrix with/without surface crack, were experimentally investigated. Hybrid laminates with eight, ten and twelve layers were prepared by employing the vacuum-assisted resin transfer molding method, while carbon and E-glass layers were stacked in an alternating sequence. Specimens were cut for uniaxial tensile loading, low-velocity Charpy impact tests, and for resin burn-off process, while additional specimens with standard artificial surface crack were also prepared for the tensile tests. The results of the quasi-static tensile tests surprisingly showed that tensile properties are a function of number of layers. It is seen that, ultimate tensile stress increases with number of plies by 20 ± 6% and 38 ± 11%, on an average basis for the uncracked and cracked specimens, respectively. This increase is less pronounced for ultimate strain and initial tensile modulus. As for the impact toughness of the specimens, those with twelve layers showed the largest toughness. In all cases, the rate of increase in mechanical properties decreases with increasing number of layers. It is also shown that the existence of surface crack generally increases the ultimate strain at the expense of a drop in ultimate tensile stress, because the laminates are more glass dominated. Reinforcement efficiency factors for uncracked specimens were found to be the constant value of 0.37. A detailed failure analysis has been also presented by scanning electron microscopy of the fracture surface. Charpy impact tests revealed that impact toughness of hybrid laminates increases with the number of layers. Failure modes are reported qualitatively in macroscopic and microscopic scales.

Graphic abstract

Similar content being viewed by others

References

Belgacem L, Ouinas D, Olay JAV, Amado AA (2018) Experimental investigation of notch effect and ply number on mechanical behavior of interply hybrid laminates (glass/carbon/epoxy). Compos B 145:189–196

Rajpurohit A, Joannès S, Singery V, Sanial P, Laiarinandrasana L (2020) Hybrid effect in in-plane loading of carbon/glass fibre based inter-and intraply hybrid composites. J Compos Sci 4:6

Khan T, Fikri A, Irfan MS, Gunister E, Umer R (2021) The effect of hybridization on microstructure and thermo-mechanical properties of composites reinforced with different weaves of glass and carbon fabrics. J Compos Mater 55:1635–1651

Robinson P, Greenhalgh E, Pinho S (eds) (2012) Failure mechanisms in polymer matrix composites: criteria, testing, and industrial applications. Woodhead Publishing, Elsevier

Razali N, Sultan MTH, Jawaid M (2019) Impact damage analysis of hybrid composite materials. In: Jawaid M, Thariq M, Saba N (eds) Durability and life prediction in biocomposites, fibre-reinforced composites and hybrid composites. Woodhead Publishing, pp 121–132

Tanks J, Sharp S, Harris D (2016) Charpy impact testing to assess the quality and durability of unidirectional CFRP rods. Polym Test 51:63–68

Fang Y, Fang Z, Xiang Y, Zhang Y (2016) The charpy impact behavior of CFRP rods and strands. In: Proceedings of the 8th International Conference on Fibre-Reinforced Polymer (FRP) Composites in Civil Engineering, CICE 2016, 1400–1404

Hufenbach W, Ibraim FM, Langkamp A, Böhm R, Hornig A (2008) Charpy impact tests on composite structures: an experimental and numerical investigation. Compos Sci Technol 68:2391–2400

Hong SW, Ahn SS, Li H, Kim JK, Ko SJ, Koo JM, Seok CS (2013) Charpy impact fracture characteristics of CFRP composite materials according to variations of fiber array direction and temperature. Int J Precis Eng Manuf 14:253–258

Hung PY, Lau KT, Cheng LK, Leng J, Hui D (2018) Impact response of hybrid carbon/glass fibre reinforced polymer composites designed for engineering applications. Compos B 133:86–90

Ebrahimnezhad-Khaljiri H, Eslami-Farsani R (2019) Experimental investigation of flexural properties of glass fiber–epoxy self-healable composite structures containing capsulated epoxy healing agent and NiCl2(imidazole) 4 catalyst. J Ind Text 4:1528083719892923

O’Donnell J, Chalivendra V (2021) Multi-functional glass/carbon fibers hybrid inter/intra laminated composites. Composites Part C 4:100121

Hashim N, Majid DLA, Mahdi ES, Zahari R, Yidris N (2019) Effect of fiber loading directions on the low cycle fatigue of intraply carbon-Kevlar reinforced epoxy hybrid composites. Compos Struct 212:476–483

Hufenbach W, Langkamp A, Hornig A, Zscheyge M, Bochynek R (2011) Analysing and modelling the 3D shear damage behaviour of hybrid yarn textile-reinforced thermoplastic composites. Compos Struct 94:121–131

Hasan MMB, Cherif C, Matthes A (2012) Early prediction of the failure of textile-reinforced thermoplastic composites using hybrid yarns. Compos Sci Technol 72:1214–1221

Selver E, Potluri P, Hogg P, Soutis C (2016) Impact damage tolerance of thermoset composites reinforced with hybrid commingled yarns. Compos B 91:522–538

Zinatloo-Ajabshir S, Mortazavi-Derazkola S, Salavati-Niasari M (2018) Nd2O3-SiO2 nanocomposites: a simple sonochemical preparation, characterization and photocatalytic activity. Ultrason Sonochem 42:71–182

Zinatloo-Ajabshir S, Salavati-Niasari M (2019) Preparation of magnetically retrievable CoFe2O4@ SiO2@ Dy2Ce2O7 nanocomposites as novel photocatalyst for highly efficient degradation of organic contaminants. Compos Part B 174:106930

Safajou H, Ghanbari M, Amiri O, Khojasteh H, Namvar F, Zinatloo-Ajabshir S, Salavati-Niasari M (2021) Green synthesis and characterization of RGO/Cu nanocomposites as photocatalytic degradation of organic pollutants in waste-water. Int J Hydrogen Energy 46:20534–20546

Zinatloo-Ajabshir S, Ghasemian N, Mousavi-Kamazani M, Salavati-Niasari M (2021) Effect of zirconia on improving NOx reduction efficiency of Nd2Zr2O7 nanostructure fabricated by a new, facile and green sonochemical approach. Ultrason Sonochem 71:105376

Vasiliev VV, Morozov EV (2018) Advanced mechanics of composite materials and structures. Elsevier, London

Mouritz AP (2012) Introduction to aerospace materials. Elsevier

Wisnom MR, Czel G, Swolfs Y, Jalalvand M, Gorbatikh L, Verpoest I (2016) Hybrid effects in thin ply carbon/glass unidirectional laminates: accurate experimental determination and prediction. Compos A 88:131–139

Voigt W (1889) Ueber die Beziehung zwischen den beiden Elasticitätsconstanten isotroper Körper. Ann Phys 274:573–587

Herakovich CT (2012) Mechanics of composites: a historical review. Mech Res Commun 41:1–20

Das O, Kim NK, Bhattacharyya D (2017). In: Ambrosio L (ed) Biomedical composites, 2nd edn. Woodhead Publ, Oxford

Erkendirci OF (2012) Charpy impact behavior of plain weave S-2 glass/HDPE thermoplastic composites. J Compos Mater 46:2835–2841

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Dahil, L., Kaya, K., Erkendirci, Ö.F. et al. Tensile strength and impact toughness of carbon/glass fiber hybrid composites with surface crack. Iran Polym J 31, 275–286 (2022). https://doi.org/10.1007/s13726-021-00984-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13726-021-00984-z