Abstract

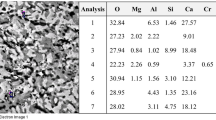

Induction motors, acting as work house of industries, are affected by winding temperature due to poor insulation. In producing a sustainable polymer composite electrical insulator, this article gets into the investigative study of tensile strength, hydrophobicity, hardness and the electrical breakdown properties of silicone rubber (SR) reinforced with sugarcane bagasse ash (SCBA). In order to identify optimal proportion, various filler proportions are studied for mechanical, physical, tensile and electrical properties. For 7% optimal filler composition, the tensile and hardness tests on SR/SCBA composite manifested a maximum value of 78.48 × 10–3 MPa and 0.91496 MPa, respectively. The electrical breakdown was recorded with the maximum value of 108.65 kV/cm with 7% filler. For hydrophobicity, the 7% filler specimens had the lowest rate of rise in weight after the water absorption test. Scanning electron microscopy (SEM) analysis and particle size analysis were carried out to evaluate the molecular interaction and particle dispersion. SEM analysis confirmed the presence of fiber-adhesion in matrix composites. Finally, the superiority of the context is also compared with earlier works. This context investigates the properties of bio-resin composite derived from sugarcane ash and creating its properties with artificial polymers to come out with a reliable electrical insulator application.

Graphic abstract

Similar content being viewed by others

References

Kumar SS, Kanagaraj G (2016) Evaluation of mechanical properties and characterization of silicon carbide-reinforced polyamide 6 polymer composites and their engineering applications. Int J Polym Anal Charact 21:378–386

Hasipoglu HN, Yilmaz E, Yilmaz O, Caner H (2005) Preparation and characterization of maleic acid grafted chitosan. Int J Polym Anal Charact 10:313–327

Gurukarthik Babu B, Prince Winston D, SenthamaraiKannan P, Saravanakumar SS, Sanjay MR (2019) Study on characterization and physicochemical properties of new natural fiber from Phaseolus vulgaris. J Nat Fibers 16:1035–1042

Thakur VK, Thakur MK, Gupta RK (2013) Graft copolymers from natural polymers using free radical polymerization. Int J Polym Anal Charact 18:495–503

Singha AS, Thakur VK (2009) Mechanical, morphological and thermal properties of pine needle-reinforced polymer composites. Int J Polym Mater Polym Biomater 58:21–31

Binoj JS, Raj RE, Daniel BSS, Saravanakumar SS (2016) Optimization of short Indian Areca fruit husk fiber (Areca catechu L.)-reinforced polymer composites for maximizing mechanical properties. Int J Polym Anal Charact 21:112–122

Gurukarthik Babu B, Prince Winston D, Aravind Bhaskar PV, Baskaran R, Narayanasamy P (2020) Exploration of electrical, thermal, and mechanical properties of phaseolus vulgaris fiber/unsaturated polyester resin composite filled with nano-SiO2. J Nat Fibers 10:1–7

Arthanarieswaran VP, Kumaravel A, Saravanakumar SS (2015) Characterization of new natural cellulosic fiber from Acacia leucophloea bark. Int J Polym Anal Charact 20:367–376

Valodkar M, Thakore S (2010) Thermal and mechanical properties of natural rubber and starch nanobiocomposites. Int J Polym Anal Charact 15:387–395

Ipakchi H, Shegeft A, Rezadoust AM, Zohuriaan-Mehr MJ, Kabiri K, Sajjadi S (2020) Bio-resourced furan resin as a sustainable alternative to petroleum-based phenolic resin for making GFR polymer composites. Iran Polym J 29:287–299

Ramanaiah K, Ratna Prasad AV, Hema Chandra Reddy K (2011) Thermal and mechanical properties of Sansevieria green fiber reinforcement. Int J Polym Anal Charact 16:602–608

Xia X, Shi X, Liu W, He S, Zhu C, Liu H (2020) Effects of gamma irradiation on properties of PLA/flax composites. Iran Polym J 29:581–590

Thakur VK, Singha AS, Kaur I, Nagarajarao RP, Liping Y (2010) Silane functionalization of Saccaharum cilliare fibers: thermal, morphological, and physicochemical study. Int J Polym Anal Charact 15:397–414

Shayan Asenjan M, Sabet SAR, Nekoomanesh M (2020) Mechanical and high velocity impact performance of a hybrid long carbon/glass fiber/polypropylene thermoplastic composite. Iran Polym J 29:301–307

Khan M, Shah Luqman A, Rehman T, Khan A, Iqbal A, Ullah M, Alam S (2020) Synthesis of physically cross-linked gum Arabic-based polymer hydrogels with enhanced mechanical, load bearing and shape memory behavior. Iran Polym J 29:351–360

Jamshaid F, Khan Rafi U, Islam A, Ahmad A, Adrees M, Dilshad R (2020) Tactical tuning of mechanical and thermo-mechanical properties of glass fiber/epoxy multi-scale composites by incorporating N-(2-aminoethyl)-3-aminopropyl trimethoxysilane functionalized carbon nanotubes. Iran Polym J 29:875–889

Jadhav Akshay C, Jadhav Nilesh C (2020) Graft copolymerization of methyl methacrylate on Meizotropis pellita fibres and their applications in oil absorbency. Iran Polym J 30:9–24

Nassar Mahmoud MA, Alzebdeh Khalid I, Pervez T, Al-Hinai N, Munam A, Al-Jahwari F, Sider I (2021) Polymer powder and pellets comparative performances as bio-based composites. Iran Polym J30:269–283

Bidgoli MF, Arabgol F, Kokabi M (2020) Ablation behavior of elastomeric insulator based on nitrile rubber containing silica or silica-clay aerogels. Iran Polym J 29:985–996

Jebadurai SG, Raj RD, Sreenivasan VS, Binoj JS (2021) Coccinia grandis stem fiber polymer composite: thermal and mechanical analysis. Iran Polym J 30:369–380

Gurukarthik Babu B, Princewinston D, Padmanaban VC, Lathief Sherief GA, Kiruba Sankar M, Aravind Bhaskar PV (2019) Optimization studies on improving the dielectric properties of alkali treated fibers from phaseolus vulgaris reinforced polyester composites by central composite design. J Nat Fibers. https://doi.org/10.1080/15440478.2019.1697985

Babu BG, Princewinston D, Saravanakumar SS, Khan A, Aravind Bhaskar PV, Indran S, Divya D (2020) Investigation on the physicochemical and mechanical properties of novel alkali-treated Phaseolus vulgaris fibers. J Nat Fibers. https://doi.org/10.1080/15440478.2020.1761930

Maheswari CU, Reddy KO, Muzenda E, Rajulu AV (2012) Tensile and thermal properties of polycarbonate-coated tamarind fruit fibers. Int J Polym Anal Charact 17:578–589

Li C, Knierim B, Manisseri C, Arora R, Scheller Henrik V, Auer M, Vogel Kenneth P, Simmons Blake A, Singh S (2010) Comparison of dilute acid and ionic liquid pretreatment of switchgrass: biomass recalcitrance, delignification and enzymatic saccharification. Bioresour Technol 101:4900–4906

Saravanakumar SS, Kumaravel A, Nagarajan T, Moorthy IG (2014) Effect of chemical treatments on physicochemical properties of Prosopis juliflora fibers. Int J Polym Anal Charact 19:383–390

Hoareau W, Trindade Wanderson G, Siegmund B, Castellan A, Frollini E (2004) Sugar cane bagasse and curaua lignins oxidized by chlorine dioxide and reacted with furfuryl alcohol: characterization and stability. Polym Degrad Stabil 86:567–576

Vimalanathan P, Venkateshwaran N, Santhanam V (2016) Mechanical, dynamic mechanical, and thermal analysis of Shorea robusta-dispersed polyester composite. Int J Polym Anal Charact 21:314–326

Maheswari CU, Reddy KO, Muzenda E, Shukla M, Rajulu AV (2013) Mechanical properties and chemical resistance of short tamarind fiber/unsaturated polyester composites: influence of fiber modification and fiber content. Int J Polym Anal Charact 18:520–533

Ishizaki Marina H, Visconte Leila LY, Furtado Cristina RG, De Oliveira MG, Leblanc Jean L (2008) Characterization of green coconut fiber composites. Int J Polym Anal Charact 13:319–330

Rajinipriya M, Nagalakshmaiah M, Astruc J, Robert M, Elkoun S (2018) Single stage purification of flax, hemp, and milkweed stem and their physical and morphological properties. Int J Polym Anal Charact 23:78–88

Agunsoye JO, Aigbodion VS (2013) Bagasse filled recycled polyethylene bio-composites: morphological and mechanical properties study. Results Phys 3:187–194

Pentakota Surya N, Prasad VVS, Ramji K, Pusty G (2014) Synthesis of bio-degradable banana nanofibers. Int J Innov Tech Res 2:730–734

Khanlou Hossein M, Woodfield P, Summerscales J, Francucci G, King B, Talebian S, Foroughi J, Hall W (2018) Estimation of mechanical property degradation of poly(lactic acid) and flax fibre reinforced poly(lactic acid) bio-composites during thermal processing. Meas J Int Meas Confed 116:367–372

Kalusuraman G, Thirumalai Kumaran S, Aslan M, Küçükömeroğluc T, Siva I (2019) Use of waste copper slag filled jute fiber reinforced composites for effective erosion prevention. Meas J Int Meas Confed 148:106950

Ashok B, Naresh S, Reddy KO, Madhukar K, Cai J, Zhang L, Rajulu AV (2014) Tensile and thermal properties of poly(lactic acid)/eggshell powder composite films. Int J Polym Anal Charact 19:245–255

Viruthagiri G, Sathiya S, Shanmugam N, Balaji A, Balamurugan K, Gopinathan E (2015) Spectroscopic investigation on the production of clay bricks with scba waste. Spectrochim Acta Part A Mol Biomol Spectrosc 149:468–475

Rajesh R, Sumathi (2020) Certain performance investigation on hybrid TiO2/Al2O3/MoS2 nanofiller coated 3\(\emptyset\) induction motor: a Taguchi and RSM based approach. Energy Rep 6:1638–1647

Kashi S, Varley R, Souza M, Al-Assafi S, Pietro A, Lavigne C, Fox B (2018) Mechanical, thermal, and morphological behavior of silicone rubber during accelerated aging. Polym Plast Technol Eng 57:1687–1696

Stalin B, Nagaprasad N, Vignesh V, Ravichandran M, Rajini N, Ismail Sikiru O, Mohammad F (2020) Evaluation of mechanical, thermal and water absorption behaviors of Polyalthia longifolia seed reinforced vinyl ester composites. Carbohydr Polym 248:116748

Oladele IO, Ajileye JO, Oke SR, Daramola OO, Adewumi OA (2020) Materials today: proceedings thermal and water absorption properties of bio-synthetic hybrid reinforced polypropylene composites. Mater Today Proc 38:994–998

Demircan G, Kisa M, Özen M, Açikgöz A, Aktaş B, Kurt Mehmet A (2020) A bio-based epoxy resin from rosin powder with improved mechanical performance. Emerg Mater Res 9:1076–1081

Demircan G, Kisa M, Ozen M, Aktas B (2020) Surface-modified alumina nanoparticles-filled aramid fiber-reinforced epoxy nanocomposites: preparation and mechanical properties. Iran Polym J 29:253–264

Thakur VK, Thakur MK, Gupta RK (2014) Review: raw natural fiber-based polymer composites. Int J Polym Anal Charact 19:256–271

Ray K, Patra H, Swain AK, Parida B, Mahapatra S, Sahu A, Rana S (2020) Glass/jute/sisal fiber reinforced hybrid polypropylene polymer composites: fabrication and analysis of mechanical and water absorption properties. Mater Today Proc 33:5273–5278

Bazli L, Eskandarinezhad S, Kakur N, Ramachandran V, Bacigalupe A, Mansilla M, Escobar M (2021) Electrical properties of polymer blend composites based on silicone rubber/EPDM/clay for high voltage insulators. J Compos Comp 3:18–24

Balamurugan N, Selvaperumal S (2019) Experimental analysis of performance and thermal capability of three phase squirrel cage induction motor using plastered composite conductors. Curr Nanomater 4:201–205

Andraschek N, Wanner AJ, Ebner C, Riess G (2016) Mica/epoxy-composites in the electrical industry: applications, composites for insulation, and investigations on failure mechanisms for prospective optimizations. Polymers 8:201

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper. The authors declare the following financial interests/personal relationships which may be considered as potential competing interests.

Rights and permissions

About this article

Cite this article

Balachandran, G.B., David, P.W., Alexander, A.B. et al. Saccharum barberi grass bagasse ash-based silicone rubber composites for electrical insulator applications. Iran Polym J 30, 1285–1296 (2021). https://doi.org/10.1007/s13726-021-00975-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13726-021-00975-0