Abstract

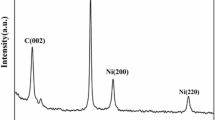

To achieve electrical conductive composites, carbon fibers (CFs) were introduced to polypropylene–thermoplastic polyurethane (PP/TPU) blends. In combination, a definite amount of silica (SiO2) nanoparticles were added as reinforcing agents to impregnate CFs and further improve the mechanical, thermal and electrical properties of CFs-modified PP/TPU composites. These quaternary composites were investigated by X-ray diffractometry technique, thermogravimetric analysis, scanning electron microscopy (SEM), mechanical measurement and electrical conductivity test. The results demonstrated that the crystallinity and flow rate of PP/TPU composites dropped after compounding with CFs, though they increased by the addition of SiO2. Both CFs and SiO2 improved the impact and tensile strength of quaternary composites, which were arising from the large aspect ratio of CFs and the reinforcement effect of SiO2 nanoparticle, respectively. Furthermore, CFs–PP/TPU and (CFs + SiO2)–PP/TPU composites exhibited superior thermal stability over PP/TPU composites, and (3CFs + 3SiO2)–PP/TPU composite exhibited a maximum value. It is attributed to the restriction of polymer chain motion created by the CF fillers and the insulating effect of SiO2. The SEM micrographs revealed the presence of plastic bands for CFs–PP/TPU and (CFs + SiO2)–PP/TPU composites and more refined arrangement of the fibers after incorporation of SiO2. This refinement resulted in higher electrical conductivity of (CFs + SiO2)–PP/TPU composites compared with CFs–PP/TPU composites.

Similar content being viewed by others

References

MastanSaheb SMD, Tambe P, Malathi M (2018) Influence of halloysite nanotubes and intumescent flame retardant on mechanical and thermal properties of 80/20 (wt/wt) PP/ABS blend and their composites in the presence of dual compatibilizer. J Thermoplast Compos 31:1–21

Szentes A, Horváth G, Varga CS (2010) Mechanical properties of polypropylene/multiwalled carbon nanotube composites. Hung J Ind Chem 38:67–70

Guan Y, Wang S, Zheng A, Xiao H (2003) Crystallization behaviors of polypropylene and functional polypropylene. J Appl Polym Sci 88:872–877

Hornsby PR (1999) Rheology, compounding and processing of filled thermoplastics. Adv Polym Sci 139:155–217

Tan JH, Wang XP, Tai JJ, Luo YF, Jia DM (2012) Novel blends of acrylonitrile butadiene rubber and polyurethane-silica hybrid networks. Express Polym Lett 6:588–600

Bakare IO, Pavithran C, Okieimen FE, Pillai CKS (2008) Synthesis and characterization of rubber-seed-oil-based polyurethanes. J Appl Polym Sci 109:3292–3301

Kannan M, Bhagawan SS, Jose T, Thomas S, Joseph K (2010) Effect of sequence of nanoclay addition in TPU/PP blends: thermomechanical properties. J Mater Sci 45:1078–1085

Seo Y, Kim J, Kim KU, Kim YC (2000) Study of the crystallization behaviors of polypropylene and maleic anhydride grafted polypropylene. Polymer 41:2639–2646

Rezaei F, Yunus R, Ibrahim NA, Mahdi ES (2008) Development of short-carbon-fiber reinforced polypropylene composite for car bonnet. Polym Plast Technol Eng 47:351–357

Rezaei F, Yunus R, Ibrahim NA (2009) Effect of fiber length on thermomechanical properties of short carbon fiber reinforced polypropylene composites. Mater Des 30:260–263

Saleem A, Frormann L, Iqbal A (2007) Mechanical, thermal and electrical resistivity properties of thermoplastic composites filled with carbon fibers and carbon particles. J Polym Res 14:121

Song J, Liu X, Zhang Y, Huang B, Yang W (2015) Carbon-fiber-reinforced acrylonitrile/styrene/acrylate composites: mechanical and rheological properties and electrical resistivity. J Appl Polym Sci 133:43252–43257

Sharma M, Gao S, Mäder E, Sharma H, Wei LY, Bijwe J (2014) Carbon fiber surfaces and composite interphases. Compos Sci Technol 102:35–50

Jin FL, Park SJ (2009) Thermal stability of trifunctional epoxy resins modified with nanosized calcium carbonate. Bull Korean Chem Soc 30:334–338

Kim KS, Rhee KY, Lee KH, Byun JH, Park SJ (2010) Rheological behaviors and mechanical properties of graphite nanoplate/carbon nanotube-filled epoxy nanocomposites. J Ind Eng Chem 16:572–576

Gibson RF (2010) A review of recent research on mechanics of multifunctional composite materials and structures. Compos Struct 92:2793–2810

Pavlidou E, Bikiaris D, Vassiliou A, Chiotelli M, Karayannidis G (2005) Mechanical properties and morphological examination of isotactic polypropylene/SiO2 nanocomposites containing PP-g-MA as compatibilizer. J Phys Conf Ser 10:190–193

Kong L, Li F, Wang F, Miao Y, Huang X, Zhu H, Lu Y (2008) In situ assembly of SiO2 nanodots/layered double hydroxide nanocomposite for the reinforcement of solution-polymerized butadiene styrene rubber/butadiene rubber. Compos Sci Technol 158:9–18

Yatsuyanagi F, Suzuki N, Ito M, Kaidou H (2001) Effects of secondary structure of fillers on the mechanical properties of silica filled rubber systems. Polymer 42:9523–9529

Xiu H, Huang CM, Bai HW, Jiang J, Chen F, Deng H, Wang K, Zhang Q, Fu Q (2014) Improving impact toughness of polylactide/poly(ether)urethane blends via designing the phase morphology assisted by hydrophilic silica nanoparticles. Polymer 55:1593–1600

Shi G, He L, Chen C, Liu J, Liu Q, Chen H (2011) A novel nanocomposite based on recycled poly(ethylene terephthalate)/ABS blends and nano-SiO2. Adv Mater Res 150–151:857–860

Yang Hong, Zhang X, Qu C (2007) Largely improved toughness of PP/EPDM blends by adding nano-SiO2 particles. Polymer 48:860–869

ZhouY HuJ, Dang B, He J (2016) Mechanism of highly improved electrical properties in polypropylene by chemical modification of grafting maleic anhydride. J Phys D Appl Phys 49:415301–415305

Liao YJ, Wu XL, Zhu L, Yi T (2018) Synthesis and properties of novel styrene acrylonitrile/polypropylene blends with enhanced toughness. Chem Cent J 12:78–87

Li Y, Wang S, Zhang Y, Zhang Y (2006) Crystallization behavior of carbon black-filled polypropylene and polypropylene/epoxy composites. J Appl Polym Sci 102:104–118

Adhikari A, Lozano K (2011) Effects of carbon nanofibers on the crystallization kinetics of polyethylene oxide. J Polym Res 18:875–880

Bian J, Wang ZJ, Lin HL, Zhou X, Xiao WQ, Zhao XW (2017) Thermal and mechanical properties of polypropylene nanocomposites reinforced with nano-SiO2 functionalized graphene oxide. Compos A 97:120–127

Gulrez SKH, Ali Mohsin ME, Al-Zahrani SM (2013) Studies on crystallization kinetics, microstructure and mechanical properties of different short carbon fiber reinforced polypropylene (SCF/PP) composites. J Polym Res 20:265

Leelachai K, Kongkachuichay P, Dittanet P (2017) Toughening of epoxy hybrid nanocomposites modified with silica nanoparticles and epoxidized natural rubber. J Polym Res 24:41–53

Miyagawa H, Drzal LT (2005) Effect of oxygen plasma treatment on mechanical properties of vapor grown carbon fiber nanocomposites. Compos A 36:1440–1448

Berlin AA, Volfson SA, Enikolopian NS (1986) Principles of polymer composites. Springer, Berlin

Marcinèin A, Hricová M, Hoferíková A (2006) Rheological properties and spinning of PP/organoclay nanocomposites. Vlákna Textil 13:1–8

Hricová M, Marcinèin A, Hoferíková A (2009) Effect of black pigments on spinning and non-uniformity of pigmented polyester fibres. In: Proceeding X. Int Conf IMTEX, Lodž, Poland 16–15: 53–56

Marcinèin A, Hricová M, Marcinèin K, Hoferíková A (2009) Study of rheological, thermal and mechanical properties of polypropylene/organoclay composites and fibres. Fibres Text East Eur 17:22–28

Frounchi M, Dourbash A (2009) Oxygen barrier properties of poly(ethylene terephthalate) nanocomposite films. Macromol Mater Eng 294:68–74

Cai Y, Ke H, Dong J, Wei Q, Lin J, Zhao Y, Song L, Hu Y, Huang F, Gao W, Fong H (2011) Effects of nano-SiO2 on morphology, thermal energy storage, thermal stability, and combustion properties of electrospun lauric acid/PET ultrafine composite fibers as form-stable phase change materials. Appl Energ 88:2106–2112

Jyoti J, Basu S, Singh BP, Dhakate SR (2015) Superior mechanical and electrical properties of multiwall carbon nanotube reinforced acrylonitrile butadiene styrene high performance composites. Compos B 83:58–65

Zhang C, Yi XS, Yui H, Asai S, Sumita M (1998) Selective location and double percolation of short carbon fiber filled polymer blends: high-density polyethylene/isotactic polypropylene. Mater Lett 36:186–190

Chen P, Chung DDL (1995) Improving the electrical conductivity of composites comprised of short conducting fibers in a nonconducting matrix: the addition of a nonconducting particulate filler. J Electron Mater 24:47–51

Acknowledgements

This work was partially supported by the Natural Science Foundation of China (61771327) and Education Office of Sichuan Province (18ZD0039).

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Wu, X., Liao, Y., Meng, G. et al. SiO2/carbon fiber-reinforced polypropylene–thermoplastic polyurethane composites: electrical conductivity and mechanical and thermal properties. Iran Polym J 28, 527–537 (2019). https://doi.org/10.1007/s13726-019-00720-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13726-019-00720-8