Abstract

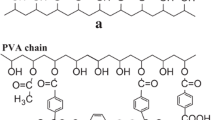

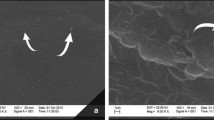

Natural rubber (HNR), produced from Hevea Brasiliensis, is being considered as the major source of 99.9% 1,4-cis-polyisoprene. Till date, this grade of natural rubber is not manufactured synthetically even using sophisticated solution polymerization techniques and utilizing the most advanced catalyst systems. Rubber industries have been continuously thriving for an alternative as well as an additional source of natural rubber to compensate for the reduction in production of Hevea natural rubber and to reduce the consumption of petroleum-based rubbers. The present study deals with chemical grafting of phosphorylated cardanol prepolymer (PCP) onto the main chain of guayule natural rubber (GNR), which could impart inherent multifunctional characteristics to the rubber. The grafting of PCP onto GNR was carried out successively using benzoyl peroxide as a free radical initiator in the solution stage and the grafting parameters have been optimized through the Taguchi method using grafting efficiency and percent grafting. Grafting of PCP onto GNR (PCP-g-GNR) was confirmed through UV–Visible, FTIR, NMR and GPC analysis. Thermal behavior of PCP-g-GNR indicates a significant increase in thermo-oxidative stability and it also displays a slight depression of glass transition temperature as compared to GNR. The viscoelastic characteristics of GNR also alter and cure characteristic improves drastically in giving rise to improved processability after grafting of the PCP. The unfilled PCP-g-GNR vulcanizates show approximately similar physico-mechanical properties with 5 phr processing oil as plasticized GNR vulcanizates. Therefore, PCP-g-GNR can be used in rubber industries as gum rubber materials as it reduces the usage of processing aids significantly.

Similar content being viewed by others

References

Rodríguez DJ, Angulo-Sánchez JL, Rodríguez-García R (2006) Mexican high rubber producing guayule shrubs: a potential source for commercial development. J Polym Environ 14:37–47

Mooibroek H, Cornish K (2000) Alternative sources of natural rubber. Appl Microbiol Biotechnol 53:355–365

Ray DT (1993) Guayule: A source of natural rubber. In: Janick J, Simon JE (eds) New crops. Wiley, New York, pp 338–342

Buranov AU, Elmuradov BJ (2009) Extraction and characterization of latex and natural rubber from rubber-bearing plants. J Agric Food Chem 58:734–743

van Beilen JB, Poirier Y (2007) Establishment of new crops for the production of natural rubber. Trends Biotechnol 25:522–529

McMahan C, Kostyal D, Lhamo D, Cornish K (2015) Protein influences on guayule and Hevea natural rubber sol and gel. J Appl Polym Sci 132:42051–42057

Cornish K, Wood DF (2002) Visualization of the malleability of the rubber core of rubber particles from Parthenium argentatum Gray and other rubber-producing species under extremely cold temperatures. J Polym Environ 10:155–162

Finlay MR (2009) Growing American Rubber: Strategic plants and the politics of national security. Studies in Modern Science, Technology, and the Environment Series. Rutgers University Press, New Brunswick. http://www.jstor.org/stable/j.ctt5hhx8h

Foster M, Coffelt T (2005) Guayule agronomics: establishment, irrigated production, and weed control. Ind Crops Prod 22:27–40

Verbiscar AJ, Banigan TF (1989) Guayule rubber, resin and bagasse recovery and purification processes. Patent US4804741A

Thuong TT, Yamamoto NO, Nghia PT, Cornish K, Kawahara S (2017) Effect of naturally occurring crosslinking junctions on green strength of natural rubber. Polym Adv Technol 28:303–311

Ikeda Y, Junkong P, Ohashi T, Phakkeeree T, Sakaki Y, Tohsan A, Kohjiyad S, Cornish K (2016) Strain-induced crystallization behaviour of natural rubbers from guayule and rubber dandelion revealed by simultaneous time-resolved WAXD/tensile measurements: indispensable function for sustainable resources. RSC Adv 6:95601–95610

Ramos-De Valle LF (1981) Vulcanization of guayule rubber. Rubber Chem Technol 54:24–33

Ramos-DeValle LF, Ramirez R (1982) Thermoplastic-guayule rubber blends-compositions and mechanical properties. Rubber Chem Technol 55:1328–1340

Barrera CS, Cornish K (2016) High performance waste-derived filler/carbon black reinforced guayule natural rubber composites rubber. Ind Crops Prod 86:132–142

Barrera CS, Cornish K (2015) Novel mineral and organic materials from agro-industrial residues as fillers for natural rubber. J Polym Environ 23:437–448

Gupta S, Mendon SK, Thames SF (2001) Applications of epoxidized and hydroxy-fluoroester pendent secondary high-molecular-weight guayule rubber in coatings. J Appl Polym Sci 82:1718–1724

Gupta S, Mendon SK, Thames SF (2004) Weathering studies of epoxidized and hydroxy-fluoroester pendent guayule rubber in powder coatings. J Appl Polym Sci 92:493–497

Thakur MK, Thakur VK, Gupta RK, Pappu A (2016) Synthesis and applications of biodegradable soy based graft copolymers: a review. ACS Sustain Chem Eng 4:1–17

Thakur VK, Singha AS, Thakur MK (2012) Graft copolymerization of methyl acrylate onto cellulosic biofibers: synthesis, characterization and applications. J Polym Environ 20:164–174

Mahata D, Prabhavale O, Samantarai S, Maity H, Ahindra N, Nando GB (2017) Functionalization of styrene–butadiene rubber with meta-pentadecenyl phenol for better processing: a multifunctional additive and renewable resource. J Appl Polym Sci 134:45150–45160

Menon ARR (1999) Melt-rheology of natural rubber modified with phosphorylated cashew nut shell liquid prepolymer- a comparative study with spindle oil. Iran Polym J 8:167–173

Menon ARR, Pillai CKS, Nando GB (1998) Vulcanization of natural rubber modified with cashew nut shell liquid and its phosphorylated derivative- a comparative study. Polymer 39:4033–4036

Menon ARR (1997) Flame-retardant characteristics of natural rubber modified with a bromoderivative of phosphorylated cashew nut shell liquid. Polymer 15:3–13

Mohapatra S, Alex R, Nando GB (2016) Cardanol grafted natural rubber: a green substitute to natural rubber for enhancing silica filler dispersion. J Appl Polym Sci 133:493–497

Mahata D, Mandal SM, Bharti R, Gupta VK, Mandal M, Nag A, Nando GB (2014) Self-assembled cardanolazo derivatives as antifungal agent with chitin-binding ability. Int J Biol Macromol 69:5–11

Pillai C, Prasad V, Sudha J, Bera S, Menon A (1990) Polymeric resins from renewable resources. II. Synthesis and characterization of flame retardant prepolymers from cardanol. J Appl Polym Sci 41:2487–2501

Taguchi G, Konishi S (2007) Orthogonal arrays and linear graphs: tools for quality engineering. Taguchi’s Quality Engineering Handbook. Wiley, New York

Dung AT, Nhan TN, Thoung TN, Nghia TP, Yamamoto Y, Kougi K, Kawahara S, Thuy TT (2017) Modification of Vietnam natural rubber via graft copolymerization with styrene. J Braz Chem Soc 28:669–675

Ma HX, Li JJ, Qiu JJ, Liu Y, Liu CM (2017) Renewable cardanol-based star-shaped prepolymer containing a phosphazene core as a potential biobased green fire-retardant coating. ACS Sustain Chem Eng 5:350–359

Christiansen SC, Hedin N, Epping JD, Janicke MT, del Amo Y, Demarest M, Brzezinski M, Chmelka BF (2006) Sensitivity considerations in polarization transfer and filtering using dipole-dipole couplings: implications for biomineral systems. Solid State Nucl Magn Reson 29:170–182

Kitamura M, Hata Y, Yasuoka H, Kurotsu T, Asano A (2012) Strain-induced 13C chemical shift change of natural rubber. Polym J 44:778–785

Kobayashi T, Lafon O, Thankamony ASL, Slowing II, Kandel K, Carnevale D, Vitzthum V, Vezin H, Amoureux JP, Bodenhausen G (2013) Analysis of sensitivity enhancement by dynamic nuclear polarization in solid-state NMR: a case study of functionalized mesoporous materials. Phys Chem Chem Phys 15:5553–5562

Mohapatra S, Nando GB (2014) Cardanol: a green substitute for aromatic oil as a plasticizer in natural rubber. RSC Adv 4:15406–15418

Gosens JC, Pratt CF, Savenije HB, Claesen CA (1993) Polymer mixture having aromatic polycarbonate, styrene containing copolymer and/or graft polymer and a flame-retardant, articles formed therefrom. Patent US 5204394

Liu YL, Hsiue GH, Chiu YS (1997) Synthesis, characterization, thermal, and flame retardant properties of phosphate based epoxy resins. J Polym Sci A: Polym Chem 35:565–574

Vikram T, Nando G (2007) Synthesis and characterization of cardanol grafted natural rubber—the solution technique. J Appl Polym Sci 105:1280–1288

David D, Rotstein N, Sincock T (1994) The application of miscibility parameter to the measurement of polymer-plasticizer compatibility. Polym Bull 33:725–732

Heymans N (2000) A novel look at models for polymer entanglement. Macromolecules 33:4226–4234

Lee HD, Kim JH, Park JH, Yoon JY, Park KU, Vo TH (2016) Novel cardanol-based organic vulcanizing agent, method for preparing the same, and rubber compound composition for tires using the same. Patent US 20160130421 A1

Menon A, Pillai C, Nando G (1994) Chemical crosslink density and network structure of natural rubber vulcanizates modified with phosphorylated cardnol prepolymer. J Appl Polym Sci 51:2157–2164

Brüning K, Schneider K, Roth SV, Heinrich G (2012) Kinetics of strain-induced crystallization in natural rubber studied by WAXD: dynamic and impact tensile experiments. Macromolecules 45:7914–7919

Mohamed R, Zain NW, Faiza A, Norizan MN (2013) Effect of epoxidized oil on tensile and tear strength of NR vulcanizate and its comparison with aromatic oil NR vulcanizates. Adv Mater Res 812:204–209

Author information

Authors and Affiliations

Corresponding authors

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Dhanania, S., Mahata, D., Prabhavale, O. et al. Phosphorylated cardanol prepolymer grafted guayule natural rubber: an advantageous green natural rubber. Iran Polym J 27, 307–318 (2018). https://doi.org/10.1007/s13726-018-0611-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13726-018-0611-z