Abstract

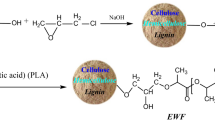

A series of polylactide/redwood flour (PLA/RWF) and polylactide/bamboo fiber (PLA/BF) composites were successfully prepared using a solution mixing procedure. Fourier transform infrared spectroscopy (FTIR) and wide-angle X-ray diffraction (XRD) were employed to characterize these composites. Thermal properties and crystallization behaviors of PLA composites were determined by their respective techniques of differential scanning calorimetry (DSC) and polarized optical microscopy (POM). With the increasing content of fibers, the glass transition temperature (T g ), crystallization temperature (T c ), and melting temperature (T m ) of PLA/RWF composites decreased first and then increased, but T g and T m of PLA/BF composites increased first and decreased afterwards. It is suggested that fibers could improve the segmental mobility of PLA; meanwhile, the different morphologies, sizes, and densities of RWF and BF have different effects on thermal properties of composites. Under the increasing content of RWF, the crystallization rate of the composite increased first and decreased afterwards. When the content of RWF was 5%, the crystallization rate was at its maximum. It could be possible that the addition of fibers was able to nucleate PLA and increase the degree of crystallinity, but the excess content of fibers easily led to heterogeneous composites and subsequent poor crystallization behaviors. In a word, thermal properties and crystallization behaviors of PLA composites were regularly changing by increasing content of fibers.

Similar content being viewed by others

References

Schnee G, Bolley A, Hild F, Specklin D, Dagorne S (2016) Group 13 metal (Al, Ga, In) alkyls supported by N-heterocyclic carbenes for use in lactide ring-opening polymerization catalysis. Catal Today (In press)

Ahmeda J, Varshney SK (2011) Polylactides—chemistry, properties and green packaging technology: a review. Int J Food Prop 14:37–58

Sutar AK, Maharana T, Dutta S, Chen C-T, Lin C-C (2009) Ring-opening polymerization by lithium catalysts: an overview. Chem Soc Rev 39:1724–1746

Afrifah KA, Matuana LM (2010) Impact modification of polylactide with a biodegradable ethylene/acrylate copolymer. Macromol Mater Eng 295:802–811

Sykacek E, Schlager W, Mundigler N (2010) Compatibility of softwood flour and commercial biopolymers in injection molding. Polym Compos 31:443–451

Kee DD, Meng Q (2014) Wood/biopolymer/nanoclay composites, cellulose based composites: new green nanomaterials, 1st edn. Wiley, New York

Spiridon I, Darie RN, Kangas H (2016) Influence of fiber modifications on PLA/fiber composites. Behavior to accelerated weathering. Compos B 92:19–27

Wang R, Yang R, Yang F (2015) Production of bamboo fiber reinforced fibrillated poly(lactic acid) (PLA) material obtained by a papermaking process. J Wuhan Univ Technol-Mat Sci Edit 30:429–432

Zhang YC, Wu HY, Qiu YP (2010) Morphology and properties of hybrid composites based on polypropylene/polylactic acid blend and bamboo fiber. Bioresour Technol 101:7944–7950

Zhang W, Chen L, Zhang Y (2009) Surprising shape-memory effect of polylactide resulted from toughening by polyamide elastomer. Polymer 50:1311–1315

Lee HS, Kim JD (2012) Effect of a hybrid compatibilizer on the mechanical properties and interfacial tension of a ternary blend with polypropylene, poly(lactic acid), and a toughening modifier. Polym Compos 33:1154–1161

Gao C, Meng L, Yu L, Simon GP, Liu H, Chen L, Petinakis S (2015) Preparation and characterization of uniaxial poly(lactic acid)-based self-reinforced composites. Compos Sci Technol 117:392–397

Lewitus D, McCarthy OA, Kenig S (2006) The effect of nanoclays on the properties of PLLA-modified polymers. Part 1: mechanical and thermal properties. J Polym Environ 14:171–177

Ye F, Dong S, Tian Z, Yao S, Zhou Z, Wang S (2015) Fabrication and characterization of long-persistent luminescence/polymer (Ca2MgSi2O7:Eu2+, Dy3+/PLA) composite fibers by electrospinning. Opt Mater 45:64–68

Pilla S, Gong S, O’Neill E, Rowell RM, Krzysik AM (2007) 9th International conference on wood & biofiber plastic composites, May 21–23, Monona Terrace Community & Convention Center Madison, Wisconsin, USA

Shah BL, Selke SE, Walters MB, Heiden PA (2008) Effects of wood flour and chitosan on mechanical, chemical, and thermal properties of polylactide. Polym Compos 29:655–663

Pilla S, Gong S, O’Neill E, Yang L, Rowell RM (2009) Polylactide-recycled wood fiber composites. J Appl Polym Sci 111:37–47

Qiang T, Yu D, Gao H (2012) Wood flour/polylactide biocomposites toughened with polyhydroxyalkanoates. J Appl Polym Sci 124:1831–1839

Georgiopoulos P, Kontou E, Niaounakis M (2014) Thermomechanical properties and rheological behavior of biodegradable composites. Polym Compos 35:1140–1149

Porras A, Maranon A (2012) Development and characterization of a laminate composite material from polylactic acid (PLA) and woven bamboo fabric. Compos B 43:2782–2788

Young WB, Tsao YC (2015) The mechanical and fire safety properties of bamboo fiber reinforced polylactide biocomposites fabricated by injection molding. J Compos Mater 49:2803–2813

Sukmawan R, Takagi H, Nakagaito AN (2016) Strength evaluation of cross-ply green composite laminates reinforced by bamboo fiber. Compos B 84:9–16

Nyambo C, Mohanty AK, Misra M (2010) Polylactide-based renewable green composites from agricultural residues and their hybrids. Biomacromolecules 11:1654–1660

Faruk O, Bledzki AK, Fink HP, Sain M (2012) Biocomposites reinforced with natural fibers: 2000–2010. Prog Polym Sci 37:1552–1596

Islam MK, Sharif A (2016) Nanocharacterization of interface between natural fiber and polymer matrix: an overview. Compos Interfaces 23:105–123

Lezak E, Kulinski Z, Masirek R, Piorkowska E, Pracella M, Gadzinowska K (2008) Mechanical and thermal properties of green polylactide composites with natural fillers. Macromol Biosci 8:1190–1200

Kawai T, Rahman N, Matsuba G, Nishida K, Kanaya T, Nakano M, Okamoto H, Kawada J, Usuki A, Honma N, Nakajima K, Matsuda M (2007) Crystallization and melting behavior of poly(l-lactic acid). Macromolecules 40:9463–9469

Na B, Tian N, Lv R, Li Z, Xu W, Fu Q (2010) Evidence of sequential ordering during cold crystallization of poly(l-lactide). Polymer 51:563–567

Zhou Y, Fan M, Chen L (2016) Interface and bonding mechanisms of plant fibre composites: an overview. Compos B 101:31–45

Acknowledgements

The authors gratefully acknowledge financial support via Research Start-up Fund of Ningbo University of Technology (Grant No. 0080011540113) and Open Fund of Key Laboratory of Marine Materials and Related Technologies, CAS and Zhejiang Key laboratory of Marine Materials and Protective Technologies.

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Yao, L., Wang, Y., Li, Y. et al. Thermal properties and crystallization behaviors of polylactide/redwood flour or bamboo fiber composites. Iran Polym J 26, 161–168 (2017). https://doi.org/10.1007/s13726-017-0508-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13726-017-0508-2