Abstract

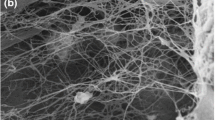

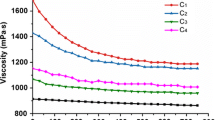

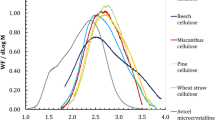

Bacterial cellulose (BC), a biodegradable polymer with high degree of crystallinity, produced by Gluconacetobacter xylinus, was used as reinforcement in biocomposites. The downstream process parameters involved in the preparation process of BC have important influence on its mechanical properties. The effect of some key processing parameters such as treatment temperature, drying stages, type of treatment solvent and pressure on biocellulose sheets was investigated during drying in order to modify the parameters responsible in mechanical properties. The rise in treatment temperature and drying processes of BC sheets showed about 8 and 11 % reduction in tensile strength, respectively. The addition of NaOH solutions during the treatment reduced the tensile strength of BC sheets sharply, though an increase in NaOH concentration produced treated samples with higher tensile modulus. The use of optimum NaClO solution as a cheap treatment solvent led to an increase of about 10–11 % in the mechanical properties of BC. A pressure increase during drying stage improved the tensile strength of biocellulose sheets by 7 % and resulted in highly enhanced tensile modulus of BC samples. The production process (microbial fermentation) and structural features (porous web-shaped structure) provide an ideal scenario for synthesis of BC composites. A number of schemes have been introduced to synthesize BC composites with different materials. Among these schemes, the initial addition of materials to BC culture media, the treatment of BC with solutions and suspensions, and the dissolution of BC in solvents are the most commonly used techniques.

Similar content being viewed by others

References

Ul-Islam M, Khan S, Ullah MW, Park JK (2015) Bacterial cellulose composites: synthetic strategies and multiple applications in biomedical and electroconductive fields. Biothechnol J 10:1847–1861

Moon RJ, Martini A, Nairn J, Simonsen J, Youngblood J (2011) Cellulose nanomaterials review: structure, properties and nanocomposites. Chem Soc Rev 40:3941–3994

Piao H (2006) Microbial-derived cellulose-reinforced biocomposites. Master’s Thesis in Mechanical Engineering, University of Canterbury, New Zealand

Yan Z, Chen S, Wang H, Wang B, Jiang J (2008) Biosynthesis of bacterial cellulose/multi-walled carbon nanotubes in agitated culture. Carbohydr Polym 74:659–665

Chiciudean TG, Stoica-Guzun A, Dobre T, Van Tooren MI (2011) High strength epoxy bacterial cellulose-based composites. Mater plast 48:159–163

Eichhorn SJ, Dufresne A, Aranguren M, Marcovich NE, Capadona JR, Rowan SJ, Weder C, Thielemans W, Roman M, Renneckar S, Gindl W, Veigel S, Keckes J, Yano H, Abe K, Nogi M, Nakagaito A, Mangalam A, Simonsen J, Benight A, Bismarck A, Berglund L, Peijs T (2010) Review: current international research into cellulose nanofibres and nanocomposites. J Mater Sci 45:1–33

Nakagaito AN, Iwamoto S, Yano H (2005) Bacterial cellulose: the ultimate nano-scalar cellulose morphology for the production of high-strength composites. Appl Phys A 80:93–97

Cai Z, Kim J (2010) Bacterial cellulose/poly (ethylene glycol) composite: characterization and first evaluation of biocompatibility. Cellulose 17:83–91

Jutras D, Qiu K, Netravali A (2009) Bacterial cellulose (BC)-based green composites. Cornell Center for Materials Research

Kaith B, Kaur I (2011) Cellulose fibers: bio-and nano-polymer composites: green chemistry and technology. Springer, New York

Li X, Tabil LG, Panigrahi S (2007) Chemical treatments of natural fiber for use in natural fiber-reinforced composites: a review. J Polym Environ 15:25–33

Scionti G (2010) Mechanical properties of bacterial cellulose implants, MS Thesis, Department of Chemical and Biological Engineering, Chalmes University of Technology, Sweden

Masoodi R, El-Hajjar RF, Pillai KM, Sabo R (2012) Mechanical characterization of cellulose nanofiber and bio-based epoxy composite. Mater Des 36:570–576

Yano H, Sugiyama J, Nakagaito AN, Nogi M, Matsuura T, Hikita M, Handa K (2005) Optically transparent composites reinforced with networks of bacterial nanofibers. Adv Mater 17:153–155

Xu S, Girouard N, Cross L, Mintz E, Schueneman G, Shofner M, Meredith C (2013) Mechanical and thermal property enhancement in cellulose nanocrystal/waterborne epoxy. Polymer 54:6589–6598

Ramamoorthy SK (2015) Properties and performance of regenerated cellulose thermoset biocomposites. Doctoral Thesis, University of Borås Sweden

Soykeabkaew N, Sian C, Gea S, Nishino T, Peijs T (2009) All-cellulose nanocomposites by surface selective dissolution of bacterial cellulose. Cellulose 16:435–444

Keshk SM (2015) Bacterial cellulose production and its industrial applications. J Bioprocess Biotech 4:1–10

Acknowledgments

The authors wish to acknowledge the financial support of the Department of Bioscience and Biotechnology of Malek, Tehran. We would like to give our sincere thanks to Dr. Habib Etemadi and Mr. Sina Sheikhhasani for their helpful discussion. Medical Engineering Laboratory, Sharif University of Technology for providing mechanical tests and Nano Electronic and Thin Film Laboratory (School of Electrical & Computer Engineering, University of Tehran) for providing SEM images are greatly acknowledged.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ebrahimi, E., Babaeipour, V. & Khanchezar, S. Effect of down-stream processing parameters on the mechanical properties of bacterial cellulose. Iran Polym J 25, 739–746 (2016). https://doi.org/10.1007/s13726-016-0462-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13726-016-0462-4