Abstract

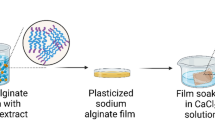

A lignin–alginate blended film was prepared in the presence of three different plasticizers, viz. glycerol, epichlorohydrin (EPC) and poly(ethylene glycol) (PEG) and the effect of each plasticizer was studied on physico-chemical properties of the blended film. Lignin extracted from Acacia wood by alkali extraction process was blended with alginate to obtain lignin–alginate film in the presence of different plasticizers. A film plasticized with glycerol displayed higher solubility and swelling percentage as compared to EPC and PEG plasticized films. The highest tensile strength was observed for film plasticized with PEG, and none of the plasticizers made any significant change on the bursting strength of the film. Incorporation of lignin considerably improved the light barrier properties of the films. Fourier transform infrared spectroscopy study of films suggested the existence of hydrogen bonding between lignin–alginate in the presence of plasticizers. In addition, EPC plasticized film displayed highest thermal stability, as confirmed by thermogravimetric analysis. Further studies demonstrated that plasticizers significantly affected the physico-chemical properties of the blended films. In conclusion, lignin–alginate film plasticized with EPC presented better physico-mechanical and light barrier properties which could be used in packaging and coating applications.

Similar content being viewed by others

References

Jost V, Kobsik K, Schmid M, Noller K (2014) Influence of plasticizer on the barrier, mechanical and grease resistance properties of alginate cast films. Carbohydr Polym 110:309–319

Huq T, Salmieri S, Khan A, Khan RA, Tien CL, Riedl B, Fraschini C, Bouchard J, Uribe-Calderon J, Kamal MR, Lacroix M (2012) Nanocrystalline cellulose (NCC) reinforced alginate based biodegradable nanocomposite film. Carbohydr Polym 90:1757–1763

Norajit K, Kim KM, Ryu GH (2010) Comparative studies on the characterization and antioxidant properties of biodegradable alginate films containing ginseng extract. J Food Eng 98:377–384

Lacroix M, Le Tien C (2005) Edible films and coatings from non-starch polysaccharides. In: Han JH (ed) Innovations in food packaging. Elsevier Science and Technology Books, San Diego, p 338

Nieto MB (2009) Structure and function of polysaccharide gum-based edible films and coatings. In: Embuscado ME, Huber KC (eds) Edible films and coatings for food applications. Springer, New York, pp 57–112

Benavides S, Villalobos-Carvajal R, Reyes JE (2012) Physical, mechanical and antibacterial properties of alginate film: effect of the crosslinking degree and oregano essential oil concentration. J Food Eng 110:232–239

Sirviö JA, Kolehmainen A, Liimatainen A, Niinimäki J, Hormi OEO (2014) Biocomposite cellulose-alginate films: promising packaging materials. Food Chem 151:343–351

Augst AD, Kong HJ, Mooney DJ (2006) Alginate hydrogels as biomaterials. Macromol Biosci 6:623–633

Fabra MJ, Flores-Lopez ML, Cerqueira MA, de Rodriguez SJ, lagaron MJ, Vicente AA (2016) Layer-by-layer technique to developing functional nanolaminate films with antifungal activity. Food Bioprocess Technol 9:471–480

Derkus B, Emregul E, Emregul KC, Yucesan C (2014) Alginate and alginate-titanium dioxide nanocomposite as electrode materials for anti-myelin basic protein immune sensing. Sens Actuator B 192:294–302

Rani P, Mishra S, Sen G (2012) Microwave based synthesis of polymethyl methacrylate grafted sodium alginate: its application as flocculant. Carbohydr Polym 91:682–685

Ionita M, Pandele MA, Iovu H (2013) Sodium alginate/graphene oxide composite films with enhanced thermal and mechanical properties. Carbohydr Polym 94:339–344

Rivero S, García MA, Pnotti A (2010) Correlations between structural, barrier, thermal and mechanical properties of plasticized gelatin films. Innov Food Sci Emerg Technol 11:369–375

Cao N, Yang X, Fu Y (2009) Effects of various plasticizers on mechanical and water vapor barrier properties of gelatin films. Food Hydrocoll 23:729–735

Jongjareonrak A, Benjakul S, Visessanguan W, Prodpran T, Tanaka M (2006) Characterization of edible films from skin gelatin of brown stripe red snapper and big eye snapper. Food Hydrocoll 20:492–501

Bergo P, Moraes ICF, Sobral PJA (2013) Effects of plasticizer on physical properties of pigskin gelatin films. Food Hydrocoll 32:412–415

Da Silva MA, Bierhalz ACK, Kieckbusch TG (2009) Alginate and pectin composite films crosslinked with Ca2+ ions: effect of the plasticizer concentration. Carbohydr Polym 77:736–742

Kittipongpatana SO, Kittipongpatana N (2013) Physicochemical, in vitro digestibility and functional properties of carboxymethly rice starch cross-linked with epichlorohydrin. Food Chem 141:1438–1444

Morin-Crini N, Crini G (2013) Environmental applications of water-insoluble β-cyclodextrin-epichlorohydrin polymers. Prog Polym Sci 38:344–368

Beyer M, Reichert J, Heurich E, Jandt KD, Sigusch BW (2010) Pectin, alginate and gum arabic polymers reduce citric acid erosion effects on human enamel. Dent Mater 26:831–839

Li Z, Ramay HR, Hauch KD, Xiao D, Zhang M (2005) Chitosan–alginate hybrid scaffolds for bone tissue engineering. Biomaterials 26:3919–3928

Bichara DA, Zhao X, Hwang NS, Bodugoz-Senturk H, Yaremchuk MJ, Randolph MA (2010) Porous poly(vinyl alcohol)-alginate gel hybrid construct for neocartilage formation using human nasoseptal cells. J Surg Res 163:331–336

Azadfar M, Gao AH, Chen S (2015) Structural characterization of lignin: a potential source of antioxidants guaiacol and 4-vinylguaiacol. Int J Biol Macromol 75:58–66

Aadil KR, Barapatre A, Sahu S, Jha H, Tiwary BN (2014) Free radical scavenging activity and reducing power of Acacia nilotica wood lignin. Int J Biol Macromol 67:220–227

Lee A, Deng Y (2015) Green polyurethane from lignin and soybean oil through non-isocyanate reactions. Eur Polym J 63:67–73

Bernardini J, Cinelli P, Anguillesi I, Coltelli MB, Lazzeri A (2015) Flexible polyurethane foams green production employing lignin or oxypropylated lignin. Eur Polym J 64:147–156

Aadil KR, Barapatre A, Meena AS, Jha H (2016) Hydrogen peroxide sensing and cytotoxicity of Acacia lignin stabilized silver nanoparticles. Int J Biol Macromol 82:39–47

Nunez-Flores R, Gimenez B, Fernandez-Martin F, Lopez-Caballero ME, Montero MP, Gomez-Guillen MC (2013) Physical and functional characterization of active fish gelatin films incorporated with lignin. Food Hydrocoll 30:163–172

Wu TL, Wang XL, Li F, Li HZ, Wang YZ (2009) Green composite films prepared from cellulose, starch and lignin in room-temperature ionic liquid. Bioresour Technol 100:2569–2574

Dong X, Dong M, Lu Y, Turley A, Jin T, Wu C (2011) Antimicrobial and antioxidant activities of lignin from residue of corn stover to ethanol production. Ind Crop Prod 34:1629–1634

Mu C, Gua J, Li X, Lin W, Li D (2012) Preparation and properties of dialdehyde carboxymethyl cellulose cross linked gelatin edible films. Food Hydrocoll 27:22–29

ASTM (2001) Standard test method for tensile properties of thin plastic sheeting, standard designation: D882, annual book of ASTM standards. American Society for Testing and Materials, Philadelphia

Flores S, Fama L, Rojas AM, Goyanes S, Gerschenson L (2007) Physical properties of tapioca-starch edible films: influence of filmmaking and potassium sorbate. Food Res Int 40:257–265

Sriamornsak P, Kennedy RA (2008) Swelling and diffusion studies of calcium polysaccharide gels intended for film coating. Int J Pharm 358:205–213

Ban W, Song J, Lucia LA (2007) Influence of natural biomaterials on the absorbency and transparency of starch-derived films: an optimization study. Ind Eng Chem Res 46:6480–6485

Bierhalz ACK, Da Silva MA, De Sousa HC, Braga MEM, Kieckbusch TG (2013) Influence of natamycin loading methods on the physical characteristics of alginate active films. J Supercrit Fluids 76:74–82

Turhan KN, Sahbaz F, Guner A (2001) A spectrophotometric study of hydrogen bonding in methylcellulose-based edible films plasticized by polyethylene glycol. J Food Sci 66:59–62

Garcia A, Toledano A, Andres MA, Labidi J (2010) Study of the antioxidant capacity of Miscanthus sinensis lignins. Proc Biochem 45:935–940

Papageorgiou SK, Kouvelos EP, Favvas EP, Sapalidis AA (2010) Metal-carboxylate interaction in metal-alginate complexes studied with FTIR spectroscopy. Carbohydr Res 345:469–473

Caykara T, Demirci S, Erogke MS, Guven O (2005) Poly(ethylene oxide) and its blends with sodium alginate. Polymer 46:10750–10757

Xiao Q, Gu X, Tan S (2014) Drying process of sodium alginate films studied by two-dimensional correlation ATR-FTIR spectroscopy. Food Chem 164:179–184

Pathak TS, Yun JH, Lee J, Paeng KJ (2010) Effect of calcium ion (cross-linker) concentration on porosity, surface morphology and thermal behavior of calcium alginates prepared from algae (Undaria pinnatifida). Carbohydr Polym 81:633–639

Acknowledgments

The authors are grateful to the University Grant Commission (UGC), New Delhi, India for funding the project vide-F. No. 41-543/2012 (SR) and to Sophisticated Test and Instrumentation Centre (STIC), Cochin University of Science and Technology, Cochin, Kerala, for sample analysis. The authors also thank Dr. Neha Pandey for help in editing the manuscript.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Aadil, K.R., Jha, H. Physico-chemical properties of lignin–alginate based films in the presence of different plasticizers. Iran Polym J 25, 661–670 (2016). https://doi.org/10.1007/s13726-016-0449-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13726-016-0449-1