Abstract

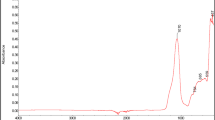

Polyethylene terephthalate (PET) waste is not biodegradable; thus, it will create environmental hazards if disposed in landfills. Therefore, the only way of addressing the problem of disposal of post-industrial and post-consumer PET wastes is through recycling. The polyester plasticizer for polyacrylonitrile butadiene rubber (NBR) and polyacrylonitrile butadiene–polyvinylchloride rubber blend (NBR–PVC) was obtained by the depolymerization of PET waste with 2-ethyl-1-hexanol. The PET waste was depolymerized until a polymeric plasticizer with the average molecular weight in the range of 450–900 g/mol was obtained. The polymeric plasticizer was characterized for acid and hydroxyl numbers, viscosity, density, FTIR, NMR and TGA/DTA thermogram. The prepared polymeric plasticizer was used in the preparation of nitrile rubber and nitrile–PVC rubber blend rubber sheets, where these sheets were tested for compatibility, tensile strength, elongation-at-break, hardness and ageing properties. Nitrile rubber and nitrile–PVC blend sheets were also prepared using DOP as a plasticizer and a comparative study with the synthesized polymeric plasticizer was made. It was observed that synthesized polymeric plasticizer provides excellent tensile properties and ageing resistance for high-performance applications as compared to that obtained from DOP. The end uses for nitrile rubber and nitrile–PVC rubber blend compounds are quite diverse, but they can be loosely categorized as being either general performances or higher performance applications. Each of these performance categories requires a different set of considerations in terms of compounding with plasticizers.

Similar content being viewed by others

References

Kint D, Muñoz-Guerra S (1999) A review on potential biodegradability of poly(ethylene terephthalate). Polym Int 48:346–352

Smith R, Oliver C, Williams DF (1987) The enzymatic degradation of polymers in vitro. J Biomed Mater Res 21:991–1003

Soni RK, Dutt K, Soam S (2009) Studies on the biodegradation of lactic acid terephathalic acid and ethylene glycol terpolymer. Polym Degrad Stabil 94:432–437

Sinha V, Patel MR, Patel JV (2010) PET waste management by chemical recycling: a review. J Polym Environ 18:8–25

Villan F, Condane J, Vert M (1995) Thermal degradation of polyethylene terephthalate: study of polymer stabilization. Polym Degrad Stabil 49:393–397

Güçlü G, Yalçinyuva T, Özgümüş S, Orbay M (2003) Hydrolysis of waste polyethylene terephthalate and characterization of products by differential scanning calorimetry. Thermochim Acta 404:193–205

Yang Y, Lu Y, Xiang H, Xu Y, Li Y (2002) Study on methanolytic depolymerization of PET with supercritical methanol for chemical recycling. Polym Degrad Stabil 75:185–191

Genta M, Uehara R, Yano F, Kondo Y, Matsubara W (2003) Development of chemical recycling process for post-consumer PET bottle by methanolysis in supercritical methanol. In: Proceedings of 6th international symposium supercritical fluids, 1381–1386

Shah RV, Borude BS, Shukla SR (2013) Recycling of PET waste using 3-amino-1-propanol by conventional or microwave irradiation and synthesis of bis-oxazin there from. J Appl Polym Sci 127:323–328

Mishra S, Goje AS (2003) Kinetics of glycolysis of poly(ethylene terephthalate) waste powder at moderate pressure and temperature. J Appl Polym Sci 87:1569–1573

Genta M, Yano F, Kondo Y, Matsubara W, Oomoto S (2003) Development of chemical recycling process for post-consumer PET bottles by methanolysis in supercritical methanol, Mitsubishi Heavy Industries, Ltd. Technical Review 40:1–4

Jain A, Soni RK (2007) Spectroscopic investigation of end products obtained by ammonolysis of poly (ethylene terephthalate) waste in the presence of zinc acetate as a catalyst. J Polym Res 14:475–481

Soni RK, Dutt K, Soam S, Jain A, Singh S (2009) A novel route of synthesis, characterization of terephthalic dihydrazide from polyethylene terephthalate waste and it’s application in PVC compounding as plasticizer. J App Polym Sci 113:1090–1096

Soni RK, Dutt K, Singh S (2010) Studies on synthesis and characterization of N-alkyl terephthalamides using different amines from polyethylene terephthalate waste. J Appl Polym Sci 115:3074–3080

Mittal A, Soni RK, Singh S, Dutt K (2010) Scanning electron microscopic study of hazardous waste flakes of polyethylene terephthalate (PET) by aminolysis and ammonolysis. J Hazard Mater 178:390–396

Liu ZH, Zhang XD, Zhu XG, Li RKY, Qi ZN, Wang FS, Choy CL (2001) Effect of morphology on the brittle ductile transition of polymer blends: 2. Analysis on poly(vinyl chloride)/nitrile rubber blends. Polymer 39:5019–5025

Zhu S-H, Chan C-M, Wong SC, Mai Y-W (1999) Mechanical properties of PVC/SBR blends compatibilized by acrylonitirile-butadiene rubber and covulcanization. Polym Eng Sci 39:1998–2006

De Zarraga A, Villanueva S, Muñoz ME, Obeso R, Peña JJ, Pascual B, Santamaría A (2004) Ternary blends to improve heat distortion temperature and rheological properties of PVC. Macromol Mater Eng 289:648–652

Ismail H, Supri AG, Yusof AMM (2004) Blend of waste poly(vinyl chloride) (PVCw)/acrylonitrile butadiene-rubber (NBR): the effet of maleic anhydride (MAH). Polym Test 23:675–683

Soni RK, Teotia M, Dutt K (2010) Studies on synthesis and characterization of a novel acrylic aromatic amide oligomer of aminolysed end products generated from PET waste with hydrazine monohydrate and its photocuring with acrylate monomers. J Appl Polym Sci 118:638–645

Acknowledgments

The author is thankful to Dr. Jay Parkesh, Principal of Bhaskaracharya College of Applied Sciences, University of Delhi, Delhi for providing the facilities to complete this research study.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Dutt, K., Soni, R.K. Synthesis and characterization of polymeric plasticizer from PET waste and its applications in nitrile rubber and nitrile–PVC blend. Iran Polym J 22, 481–491 (2013). https://doi.org/10.1007/s13726-013-0148-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13726-013-0148-0