Abstract

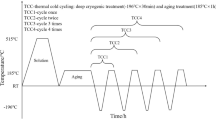

The research investigates the impact of aging heat treatment on the microstructure and properties of an Al–Cu–Mg alloy. A series of controlled aging experiments examined the alloy’s microstructure using advanced microscopy techniques, including optical microscopy, scanning electron microscopy, and X-ray diffraction (XRD). Furthermore, mechanical properties such as hardness and compressive strength were evaluated to quantify the alloy’s response to aging. The relationship between the observed microstructural modifications and the resulting mechanical properties is discussed, shedding light on optimizing aging heat treatment. This study contributes to a deeper understanding of the interplay between microstructure and properties in metal alloys, facilitating the design and development of materials with tailored mechanical behavior.

Similar content being viewed by others

References

F. Shen, W. Li, Z. Sun, Z. Zhou, C. Xie, Z. Liao, D. Yi, Insights of texture and microstructure evolution in the short time annealing of Al–Cu–Mg alloy at large temperature range. J. Alloys Compd. 871, 159613 (2021). https://doi.org/10.1016/j.jallcom.2021.159613

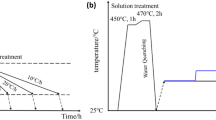

N. Patel, M. Joshi, A. Singh, A.K. Pradhan, Effect of solution heat treatment on microstructure and some properties of Al–Cu–Mg alloy. Trans. Indian Inst. Met. 76, 2681–2689 (2023). https://doi.org/10.1007/s12666-023-02961-x

N. Patel, S. Manani, A.K. Pradhan, Effect of addition of Cu on microstructure and some properties of 5754 aluminum alloy. Trans. Indian Inst. Met. 76, 1929–1936 (2023). https://doi.org/10.1007/s12666-023-02904-6

N. Patel, M. Joshi, A. Singh, G.N. Mittal, M. Agrawal, S. Manani, A.K. Pradhan, Effect of solution heat treatment (temperature and time) on microstructure and properties of Al–Cu–Mg alloy. Int. J. Met. (2023). https://doi.org/10.1007/s40962-023-01095-6

T. Huang, F. Liu, Z. Liu, G. He, Evolution of microstructure, texture, and hardness in an Al–Cu–Mg alloy during annealing. J. Mater. Eng. Perform. 31, 1419–1431 (2022). https://doi.org/10.1007/s11665-021-06265-3

A. Alil, M. Popović, T. Radetić, M. Zrilić, E. Romhanji, Influence of annealing temperature on the baking response and corrosion properties of an Al–4.6 wt% Mg alloy with 0.54 wt% Cu. J. Alloys Compd. 625, 76–84 (2015). https://doi.org/10.1016/j.jallcom.2014.11.063

F. Shen, Z. Zhou, W. Li, Z. Sun, J. Tian, C. Xie, J. Guo, Z. Liao, D. Yi, J. Zhang, H. Wang, B. Jiang, Micro-mechanism of texture evolution during isochronal annealing of as-annealed hot rolled Al–Cu–Mg sheet. Mater. Des. 165, 107575 (2019). https://doi.org/10.1016/j.matdes.2018.107575

M. Agilan, G. Phanikumar, D. Sivakumar, Weld solidification cracking behaviour of AA2195 Al–Cu–Li alloy. Trans. Indian Inst. Met. 71, 2667–2670 (2018). https://doi.org/10.1007/s12666-018-1425-6

A.K. Birru, D.B. Karunakar, M.M. Mahapatra, A study on hot tearing susceptibility of Al–Cu, Al–Mg, and Al–Zn alloys. Trans. Indian Inst. Met. 65, 97–105 (2012). https://doi.org/10.1007/s12666-011-0112-7

M. Zamani, S. Toschi, A. Morri, L. Ceschini, S. Seifeddine, Optimisation of heat treatment of Al–Cu–(Mg–Ag) cast alloys. J. Therm. Anal. Calorim. 139, 3427–3440 (2020). https://doi.org/10.1007/s10973-019-08702-x

N. Chobaut, D. Carron, J.-M. Drezet, Characterisation of precipitation upon cooling of an AA2618 Al–Cu–Mg alloy. J. Alloys Compd. 654, 56–62 (2016). https://doi.org/10.1016/j.jallcom.2015.09.113

J.-H. Jang, D.-G. Nam, Y.-H. Park, I.-M. Park, Effect of solution treatment and artificial aging on microstructure and mechanical properties of Al–Cu alloy. Trans. Nonferrous Met. Soc. China. 23, 631–635 (2013). https://doi.org/10.1016/S1003-6326(13)62509-1

İ Özbek, A study on the re-solution heat treatment of AA 2618 aluminum alloy. Mater Charact. 58, 312–317 (2007). https://doi.org/10.1016/j.matchar.2006.07.002

I. Zuiko, R. Kaibyshev, Aging behavior of an Al–Cu–Mg alloy. J. Alloys Compd. 759, 108–119 (2018). https://doi.org/10.1016/j.jallcom.2018.05.053

I.S. Zuiko, M.R. Gazizov, R.O. Kaibyshev, Effect of thermomechanical treatment on the microstructure, phase composition, and mechanical properties of Al–Cu–Mn–Mg–Zr alloy. Phys. Met. Metallogr. 117, 906–919 (2016). https://doi.org/10.1134/S0031918X16090088

G. Bo, F. Jiang, H. Su, L. Wu, J. Teng, D. Fu, H. Zhang, Static softening behavior and modeling of an Al–Cu–Mg–Zr alloy with various pre-precipitation microstructures during multistage hot deformation. Mater. Sci. Eng. A. 778, 139094 (2020). https://doi.org/10.1016/j.msea.2020.139094

N. Patel, S. Manani, A.K. Pradhan, Influence of copper addition on microstructure, mechanical and thermal properties of Al–12.6%Zn–Mg alloys. Int. J. Met. (2023). https://doi.org/10.1007/s40962-023-01202-7

N. Patel, A.K. Pradhan, Influence of copper addition on microstructure, mechanical and thermal properties of Al-Zn-Mg alloys. Int. J. Met. (2023). https://doi.org/10.1007/s40962-023-01214-3

N. Patel, A.K. Pradhan, Mechanical properties, thermal properties and microstructure of heat-treated Al-Zn-Mg-x%Cu (0.02 wt% Cu and 0.89 wt% Cu) alloy. Int. J. Met. (2024). https://doi.org/10.1007/s40962-023-01232-1

M.F. Ibrahim, A.M. Samuel, F.H. Samuel, A preliminary study on optimizing the heat treatment of high strength Al–Cu–Mg–Zn alloys. Mater. Des. 57, 342–350 (2014). https://doi.org/10.1016/j.matdes.2013.11.078

N. Nafsin, H. Rashed, Effects of copper and magnesium on microstructure and hardness of Al–Cu–Mg alloys. Int. J. Eng. Adv. Technol. IJEAT. 2, 533–536 (2013)

O. Engler, C.D. Marioara, T. Hentschel, H.-J. Brinkman, Influence of copper additions on materials properties and corrosion behaviour of Al–Mg alloy sheet. J. Alloys Compd. 710, 650–662 (2017). https://doi.org/10.1016/j.jallcom.2017.03.298

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Agrawal, M., Mittal, G., Patel, N. et al. Effect of Aging Heat Treatment on Microstructure and Properties of Al–Cu–Mg Alloy. Metallogr. Microstruct. Anal. (2024). https://doi.org/10.1007/s13632-024-01076-z

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s13632-024-01076-z