Abstract

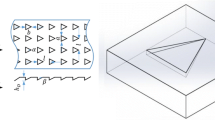

High-quality Japanese swords display a pattern just below the spine called the utsuri pattern. The physical mechanism causing this pattern remains a mystery. An hypothesis is presented here postulating that the pattern is produced by a transition in the microstructure from pearlite to the product microstructure of the divorced eutectoid transformation, DET. Experiments are presented in which such a transition was produced on small blade pieces. It is demonstrated that the contrast on these blades is adequate to produce the utsuri patterns.

Similar content being viewed by others

References

L. Kapp, H. Kapp, Y. Yoshihara, The Craft of the Japanese Sword (Kondansha, USA, 1987), p. 91

H.C. Sorby, The contribution of Henry Clifton Sorby to the study of reflected light microscopy of iron and steel. J. Iron. Steel. Inst. 1, 140–147 (1886)

H.M. Howe, The Metallurgy of Steel. Eng. Min. J. 46, 131–132 (1888)

K. Hondo, S. Saito, On the formation of spheroidal cementite. J. Iron. Steel. Inst. 102(2), 261–269 (1920)

J.H. Whiteley, Formation of globular pearlite. J. Iron. Steel. Inst. 105, 339–357 (1922)

P. Payson, W.L. Hodapp, J. Leeder, The spheroidization of steel by isothermal transformation. Trans. ASM. 28, 306 (1940)

T. Oyama, O.D. Sherby, J. Wadsworth, B. Walser, Application of the divorced eutectoid transformation to the development of fine grained spheroidized structures in ultrahigh carbon steels. Scripta. Metall. 18, 799–804 (1984)

J.D. Verhoeven, E.D. Gibson, The divorced eutectoid transformation in steel. Met. Mat. Trans. A. 29A, 1181–1189 (1998)

N.V. Luzginnova, L. Zhao, J. Seitsma, The cementite spheroidization process in high carbon steels with different chromium contents. Met. Mat. Trans A. 39A, 513–521 (2008)

A.S. Pandit, H.K.D.H. Bhadishia, Divorced pearlite in steels. Proc. Roy. Soc. A. 10, 1–14 (2012)

T. Zowada, J.D. Verhoeven, A study of the divorced eutectoid transformation, DET, in eutectoid composition plain carbon steel. Metallogr. Microstruct. Anal. 13(1), 1–15 (2024)

G. Krauss, Steels heat treatment and processing principles. ASM. Int. 94 (1980)

Acknowledgements

The experimental work was done in the two metallurgy shops of the authors. Mr William Dauksch, ex vice president of Nucor Steel, provided the financial support for the chemical analysis done at Chicago Spectro Lab.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Zowada, T., Verhoeven, J.D. A Hypothesis for the Mechanism that Produces the Utsuri Pattern on Japanese Swords. Metallogr. Microstruct. Anal. 13, 62–67 (2024). https://doi.org/10.1007/s13632-023-01037-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13632-023-01037-y