Abstract

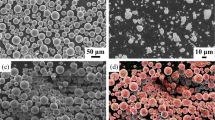

Ti-6Al-4V alloy has specific properties to meet the industrial application. The present work discusses the variant selection in the thermally treated Ti-6Al-4V alloys processed by laser metal deposition (LMD). It is found that the variant selection is strengthened by thermal cycles. The thermally treated Ti-6Al-4V alloy has the grain boundary α (αGB) and Widmanstätten microstructure. And the Widmanstätten microstructure develops from α grain boundaries (αWGB) and follows the Burgers boundary orientation relationship (BOR). This work explores the variant selection when the LMD-ed Ti-6Al-4V undergoes the thermal treatment.

Similar content being viewed by others

Data availability

The data that support the findings of this study are available from the corresponding author upon reasonable request.

References

G. Lütjering, J.C. Williams, Beta alloys, Titanium (2007) pp. 283–336

S. Gorsse, C. Hutchinson, M. Gouné, R. Banerjee, Additive manufacturing of metals: a brief review of the characteristic microstructures and properties of steels, Ti-6Al-4V and high-entropy alloys. Sci. Technol. Adv. Mater. 18(1), 584–610 (2017)

T. Vilaro, C. Colin, J.-D. Bartout, As-fabricated and heat-treated microstructures of the Ti-6Al-4V alloy processed by selective laser melting. Metall. Mater. Trans. A. 42(10), 3190–3199 (2011)

Y. Lu, H. Tang, Y. Fang, D. Liu, H. Wang, Microstructure evolution of sub-critical annealed laser deposited Ti–6Al–4V alloy. Mater. Des. 37, 56–63 (2012)

S. Wu, Y. Lu, Y. Gan, T. Huang, C. Zhao, J. Lin, S. Guo, J. Lin, Microstructural evolution and microhardness of a selective-laser-melted Ti–6Al–4V alloy after post heat treatments. J. Alloy. Compd. 672, 643–652 (2016)

B. Vrancken, L. Thijs, J.-P. Kruth, J. Van Humbeeck, Heat treatment of Ti6Al4V produced by selective laser melting: microstructure and mechanical properties. J. Alloy. Compd. 541, 177–185 (2012)

C. Liu, H. Wang, X. Tian, D. Liu, Development of a pre-heat treatment for obtaining discontinuous grain boundary α in laser melting deposited Ti–5Al–5Mo–5V–1Cr–1Fe alloy. Mater. Sci. Eng. A. 604, 176–182 (2014)

Z. Sun, S. Guo, H. Yang, Nucleation and growth mechanism of α-lamellae of Ti alloy TA15 cooling from an α+ β phase field. Acta Mater. 61(6), 2057–2064 (2013)

Z. Sun, X. Li, H. Wu, H. Yang, A unified growth model of the secondary grain boundary α phase in TA15 Ti-alloy. J. Alloy. Compd. 689, 693–701 (2016)

R. Banerjee, D. Bhattacharyya, P. Collins, G. Viswanathan, H. Fraser, Precipitation of grain boundary α in a laser deposited compositionally graded Ti–8Al–xV alloy–an orientation microscopy study. Acta Mater. 52(2), 377–385 (2004)

N. Stefansson, S. Semiatin, D. Eylon, The kinetics of static globularization of Ti-6Al-4V. Metall. Mater. Trans. A. 33, 3527–3534 (2002)

S. Zherebtsov, M. Murzinova, G. Salishchev, S. Semiatin, Spheroidization of the lamellar microstructure in Ti–6Al–4V alloy during warm deformation and annealing. Acta Mater. 59(10), 4138–4150 (2011)

N. Stefansson, S. Semiatin, Mechanisms of globularization of Ti-6Al-4V during static heat treatment. Metall. Mater. Trans. A. 34, 691–698 (2003)

E. Shell, S. Semiatin, Effect of initial microstructure on plastic flow and dynamic globularization during hot working of Ti-6Al-4V. Metall. Mater. Trans. A. 30(12), 3219–3229 (1999)

S. Wang, M. Aindow, M. Starink, Effect of self-accommodation on α/α boundary populations in pure titanium. Acta Mater. 51(9), 2485–2503 (2003)

Y. Chai, H. Kim, H. Hosoda, S. Miyazaki, Self-accommodation in Ti–Nb shape memory alloys. Acta Mater. 57(14), 4054–4064 (2009)

J. Yang, H. Yu, J. Yin, M. Gao, Z. Wang, X. Zeng, Formation and control of martensite in Ti-6Al-4V alloy produced by selective laser melting. Mater. Des. 108, 308–318 (2016)

M. Salib, J. Teixeira, L. Germain, E. Lamielle, N. Gey, E. Aeby-Gautier, Influence of transformation temperature on microtexture formation associated with α precipitation at β grain boundaries in a β metastable titanium alloy. Acta Mater. 61(10), 3758–3768 (2013)

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Li, W., Zheng, K., Zhao, G. et al. Variant Selection in the Thermally Treated Ti-6Al-4V Processed by Laser Metal Deposition. Metallogr. Microstruct. Anal. 12, 645–650 (2023). https://doi.org/10.1007/s13632-023-00975-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13632-023-00975-x