Abstract

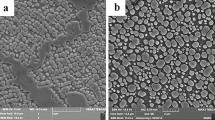

In this research, the samples were exposed to full and partial solution heat treatments and quenched in the air and nitrogen each period. Also, one sample was kept in the liquid nitrogen for 2 h after cooling in the air and isothermal process. In the end, the samples were aged. At every stage, samples were investigated using scanning electron microscope (SEM) and microhardness HV test. The results showed that the rejuvenation heat treatment leads to formation of nanoprecipitates with the cubic morphology in the matrix. The percentage of nanoprecipitates after aging increased by about 87/8%. Keeping in the liquid nitrogen after full solution increased the volume fraction of the small precipitates by about 85%. After partial solution heat treatment, the precipitates became coarse and volume fraction increased to 74%. By increasing the cooling rate, microhardness increased from 620 to 786 microhardness HV after aging. After solutionizing and high rate quench, the microhardness of the blade airfoil decreased to 361 HV, which means a successful solutionizing as the main stage of rejuvenation. During rejuvenation, the size and volume fraction of γ´ precipitates decreased in the solution step and increased by aging. The use of cryogenics and the high rate of quench caused the improvement in the rejuvenation process compared to previous researches. This research can be a start for using this new method of rejuvenation.

Similar content being viewed by others

References

C. Yang, H. Nie, Y. Xu, Z. Shen, Effects of heat treatments on the microstructure and mechanical properties of Rene 80. Mater. Des. 43, 66–73 (2013)

Y.Q. Chen, T.J.A. Slater, E.A. Lewis, E.M. Francis, M.G. Burke, M. Preuss, S.J. Haigh, Measurement of size-dependent composition variations for gamma prime (γ′) precipitates in an advanced nickel-based superalloy. Ultramicroscopy. 144, 1–8 (2014)

H.T. Mallikarjuna, W.F. Caley, N.L. Richards, The dependence of oxidation resistance on gamma prime intermetallic size for superalloy IN738LC. Corros. Sci. 147, 394–405 (2019)

Y.Q. Chen, E. Francis, J. Robson, M.P. Reuss, S.J. Haigh, different cooling rates in an advanced Ni-based superalloy. Acta Mater. 85, 199–206 (2015)

W. Hongyu, X. Zhuang, Y. Nie, Y. Li, L. Jiang, Effect of heat treatment on mechanical property and microstructure of a powder metallurgy nickel-based superalloy. Mater. Sci. Eng. A. 754, 29–37 (2019)

Y. Shajari, S.H. Razavi, Z.S. Seyedraoufi, M. Samiee, The effect of time and temperature of solutionizing heat treatment on γ′ characterization in a Ni-Base superalloy. Metallogr. Microstruct. Anal. 10, 441–447 (2021)

Z. Mazur, A.L. Ramirez, J.A. Islas, C. Amezcua, Failure analysis of a gas turbine blade made of Inconel 738LC alloy. Eng. Fail. Anal. 12, 474–486 (2015)

M.M. Barjesteh, S.M. Abbasi, K. Zangeneh Madar, K. Shirvani, The effect of heat treatment on characteristics of the gamma prime phase and hardness of the nickel-based superalloy Rene 80. Mater. Chem. Phys. 227, 46–55 (2019)

Z. Liao, D. Axinte, M. Mieszala, R. M’Saoubi, J. Michler, M. Hardyd, On the influence of gamma prime upon machining of advanced nickel based superalloy. CIRP Ann. 67, 109–112 (2018)

J. Safari, S. Nategh, On the heat treatment of Rene80 nickel-base superalloy. J. Mater. Process. Tech. 176, 240–250 (2006)

X. Qin, J. Guo, C. Yuan, M.Y. Cuilian, C. Chunlin, Decomposition of primary MC carbide and its effects on the fracture behaviors of a cast Ni-base superalloy. Mater. Sci. Eng. A. 458, 74–79 (2008)

J.R. May, M.C. Hardy, M.R. Bache, D.D. Kaylor, Microstructure and mechanical properties of an advanced nickel-Based superalloy in the as-hip form. Adv. Mat. Res. 278, 265–270 (2011)

N. Kontikame, S. Polsilapa, P. Wangyao, Effect of precipitation aging temperatures on reheat treated microstructures and its phase stability after long-term exposure in cast nickel base superalloy. Mater. Sci. 891, 433–437 (2017)

E. Lvova, D. Norsworthy, Influence of service-induced microstructural changes on the aging kinetics of rejuvenated Ni-based superalloy gas turbine blades. J. Mater. Eng. Perform. 10, 299–313 (2001)

Y. Shajari, Z.S. Seyedraoufi, A. Alizadeh, S.H. Razavi, M. Porhonar, K. Mirzavand, Effect of solution temperature of rejuvenation heat treatment on the stability of γ’ precipitates in Ni-base superalloy IN738LC during long-term heating. Mater. Res. Express. 6, 126571 (2019)

S.R. Bell, Repair and rejuvenation procedures for aero gas turbine hot section components. J. Mat. Sci. Tech. 2, 629–634 (1985)

X. Fan, A. Zhang, Z. Guo, X. Wang, J. Yang, J. Zou, Growth behavior of γ′ phase in a powder metallurgy nickel-based superalloy under interrupted cooling process. J. Mater. Sci. 54, 2680–2689 (2019)

S. Xiang, S. Mao, H. Wei, Y. Liu, J. Zhang, Z. Shen, H. Long, H. Zhang, X. Wang, Z. Zhang, X. Han, Selective evolution of secondary γ′ precipitation in a Ni-based single crystal superalloy both in the γ matrix and at the dislocation nodes. Acta. Mater. 116, 343–353 (2016)

M.P. Jackson, M.J. Starink, R.C. Reed, Determination of the precipitation kinetics of Ni3Al in the Ni-Al system using differential scanning calorimetry. Mater. Sci. Eng. 264, 26–38 (1999)

H.J. Penkalla, J. Wosik, A.C. Filemonowicz, Quantitative microstructural characterization of Ni-base superalloys. Mater. Chem. Phys. 81, 417–423 (2003)

H.H. Dastgerdi, M. Ostad Shabani, Y. Shajari, The effect of cooling rate on the solutionizing of IN718 superalloy produced via selective laser melting (SLM) method. J. Environ. Friend. Mater. 3, 17–22 (2019)

N. El Bagoury, M. Waly, A. Nofal, Effect of various heat treatment conditions on the microstructure of cast polycrystalline IN738LC alloy. Mater. Sci. Eng. A. 487, 152–161 (2008)

J. Tiley, G.B. Viswanathan, R. Srinivasan, R. Banerjee, Coarsening kinetics of γ′ precipitates in the commercial nickel-base superalloy René 88 DT. Acta. Mater. 57, 2538–2549 (2009)

A. Khodabakhsh, A. Mashreghi, Y. Shajari, S.H. Razavi, Investigation of microstructure properties and quantitative metallography by different etchants in the service-exposed nickel-based superalloy turbine blade. Trans. Indian Inst. Met. 71, 849–859 (2018)

A. Polkowska, W. Polkowski, M. Warmuzek, N. Cieśla, G. Włoch, D. Zasada, R.M. Purgert, Microstructure and hardness evolution in haynes 282 nickel-based superalloy during multi-variant aging heat treatment. J. Mater. Eng. Perform. 28, 3844–3851 (2019)

Y. Shajari, S.H. Razavi, Z.S. Seyedraoufi, Comparative study of solution heat treatment of IN738LC superalloy in conventional conditions and salt bath. J. Mater. Eng. Perform. 31, 2525–2541 (2022)

M. Qian, J.C. Lippold, The effect of rejuvenation heat treatments on the repairweldability of wrought alloy 718. Mater. Sci. Eng. A. 340, 225–231 (2003)

B. Galizoni, A.A. Couto, D. Reis, Heat treatments effects on nickel based superalloy inconel 713C. Defect. Diffusion. Forum. 9, 32–40 (2019)

J. Brenneman, J. Wei, Z. Sun, L. Liu, G. Zou, Y. Zhou, Oxidation behavior of GTD111 Ni-based superalloy at 900 °C in air. Corros. Sci. 100, 267–274 (2015)

Z. Yao, C.C. Degnan, R.C. Thomson, Effect of rejuvenation heat treatments on gamma prime distributions in a Ni based superalloy for power plant applications. Mater. Sci. Tech. 29, 775–780 (2013)

S. Saladi, J.V. Menghani, S. Prakash, Characterization and evaluation of cyclic hot corrosion resistance of detonation-gun sprayed Ni-5Al coatings on inconel 718. J. Thermal. Spray. Tech. 24, 778–788 (2015)

S.H. Razavi, S.S. Mirdamadi, H. Arabi, J. Szpunar, Mathematical model of influence of rapid induction heating on nucleation and growth of precipitates. Mater. Sci. Tech. 17, 1205–1210 (2001)

A. Baldan, Rejuvenation procedures to recover creep properties of nickel-base superalloys by heat treatment and HIP techniques. J. Mater. Sci. 26, 3409–3421 (1991)

C. Monti, A. Giorgetti, L. Tognarelli, F. Mastromatteo, On the effects of the rejuvenation treatment on mechanical and microstructural properties of IN738 superalloy. J. Mater. Eng. Perform. 26, 2244–2256 (2017)

A. Yang, Y. Xiong, L. Liu, Effect of cooling rate on the morphology of γ’ precipitates in a nickel-base superalloy under directional solidification. Sci. Tech. Adv. Mater. 2, 105–107 (2001)

N. Hashemi, Z.S. Seyedraoufi, Y. Shajari, The effect of partial solution heat treatment parameters on microstructure evaluation of IN792 superalloy. Metallogr. Microstruct. Anal. 10, 627–633 (2021)

R.J. Mitchell, M. Preuss, S. Tin, M.C. Hardy, The influence of cooling rate from temperatures above the γ′ solvus on morphology mismatch and hardness in advanced polycrystalline nickel-base superalloys. Mater. Science. Eng. A. 473, 158–165 (2008)

B. Ruttert, D. Burger, L.M. Roncery, P.A.B. Arsa, Rejuvenation of creep resistance of a Ni-base single-crystal superalloy by hot isostatic pressing. Mater. Des. 134, 418–425 (2017)

H. Yang, J. Zhang, Z. Zhang, Rejuvenation heat treatment’s influence on the microstructure and properties of superalloys. Mater. Sci. Tech. 18, 1018–1024 (2018)

Y. Gai, R. Zhang, J. Yang, C. Cui, J. Qu, Effects of heat treatment on γ′ precipitates and tensile properties of a Ni-base superalloy. Mater. Sci. Eng. A. 842, 143079 (2022)

R.S. Moshatghin, S. Asgari, The effect of thermal exposure on the characteristics in a Ni-base superalloy. J. Alloys. Compd. 368, 144–151 (2004)

P.M. Mignanelli, N.G. Jones, M.C. Hardy, H.J. Stone, The Influence of Al-Nb Ratio on The Microstructure and Mechanical Response of Quaternary Ni–Cr–Al–Nb Alloys. Mater. Sci. Eng. A. 612, 179–186 (2014)

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Samiee, M., Shajari, Y., Razavi, S.H. et al. Effect of Cryogenic Treatment After Full Solution on Rejuvenation of Exposed IN738LC Gas Turbine Blade. Metallogr. Microstruct. Anal. 12, 4–14 (2023). https://doi.org/10.1007/s13632-022-00917-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13632-022-00917-z