Abstract

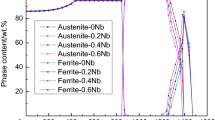

S400E stainless steel is a new type of sorbite stainless steel that has been developed in China recently. S400E stainless steel exhibits good mechanical properties, corrosion resistance, and weldability due to the alloying elements. However, the corrosion and microstructure role has not been understood extensively. This paper investigates the electrochemical corrosion properties, microstructure, and phase diagram of the new S400E sorbite stainless steel. The corrosion potential and pitting potential of the S400E are higher than the 12Cr13, indicating better corrosion resistance. The microstructure by SEM and EPMA illustrated that chromium carbides are distributed homogenously in the S400E stainless steel but heterogenous in the 12Cr13 stainless steel. The calculated phase diagram shows that the increase in the P element content in the S400E stainless steel will expand the M3P and M (C, N) phase regions; furthermore, the calculated phase diagram shows that the S400E stainless steel temperature from 900–1000°C has ferrite and austenite region, whereas 12Cr13 have austenite phase at that temperature.

Similar content being viewed by others

References

Edqm Committee of Experts on Packaging Materials for Food and Pharmaceutical Products ω P-SC-EMB

N.R. Baddoo, Stainless steel in construction: a review of research, applications, challenges and opportunities. J. Constr. Steel Res. 64, 1199–1206 (2008). https://doi.org/10.1016/j.jcsr.2008.07.011

A.H. Committee, Properties and Selection: Irons, Steels, and High-Performance Alloys (ASM International, Ohio, 2018)

T. Manninen, J. Säynäjäkangas, Mechanical Properties of Ferritic Stainless Steels at Elevated Temperature

Gunilla, Bioaccessibility of Stainless Steels – Importance of Bulk and Surface Features (2008)

M. Lundin, Y. Hedberg, T. Jiang et al., Adsorption and protein-induced metal release from chromium metal and stainless steel. J. Colloid Interface Sci. 366, 155–164 (2012). https://doi.org/10.1016/j.jcis.2011.09.068

M.G. Shettlemore, K.J. Bundy, Examination of in vivo influences on bioluminescent microbial assessment of corrosion product toxicity. Biomaterials. 22, 2215–2228 (2001). https://doi.org/10.1016/S0142-9612(00)00410-5

S. Karimi, T. Nickchi, A.M. Alfantazi, Long-term corrosion investigation of AISI 316L, Co-28Cr-6Mo, and Ti-6Al-4V alloys in simulated body solutions. Appl. Surf. Sci. 258, 6087–6096 (2012). https://doi.org/10.1016/j.apsusc.2012.03.008

J. Pan, C. Karlén, C. Ulfvin, Electrochemical study of resistance to localized corrosion of stainless steels for biomaterial applications. J. Electrochem. Soc. 147, 1021 (2000). https://doi.org/10.1149/1.1393307

M. Accominotti, M. Bost, P. Haudrechy et al., Contribution to chromium and nickel enrichment during cooking of foods in stainless steel utensils. Contact Dermatitis. 38, 305–310 (1998). https://doi.org/10.1111/j.1600-0536.1998.tb05763.x

A.N. Isfahany, H. Saghafian, G. Borhani, The effect of heat treatment on mechanical properties and corrosion behavior of AISI420 martensitic stainless steel. J. Alloys Compd. 509, 3931–3936 (2011). https://doi.org/10.1016/j.jallcom.2010.12.174

S.K. Bhambri, Intergranular fracture in 13 wt% chromium martensitic stainless steel. J. Mater. Sci. 21, 1741–1746 (1986). https://doi.org/10.1007/BF01114734

Phase transformations in metals and alloys by David a Porter, MD, PhD - Alibris. https://www.alibris.com/Phase-transformations-in-metals-and-alloys-David-a-Porter-MD-PhD/book/5096543. Accessed 16 Dec 2020

S. Kumar, R.P. Kushwaha, B.C. Maji et al., Phase-dependent tensile properties of 9Cr-1Mo(V, Nb) ferritic/martensitic steel. Metall. Mater. Trans. A. 45, 531–536 (2014). https://doi.org/10.1007/s11661-013-2151-7

S. Marcelin, N. Pébère, S. Régnier, Electrochimica acta electrochemical characterisation of a martensitic stainless steel in a neutral chloride solution. Electrochim. Acta. 87, 32–40 (2013). https://doi.org/10.1016/j.electacta.2012.09.011

J.W. Oldfield, W.H. Sutton, Crevice corrosion of stainless steels: I. A mathematical model. Br. Corros. J. 13, 13–22 (1978). https://doi.org/10.1179/000705978798358671

X.P. Ma, L.J. Wang, C.M. Liu, S. Subramanian, Microstructure and properties of 13Cr5Ni1Mo0.025Nb0.09V0.06N super martensitic stainless steel. Mater. Sci. Eng. A. 539, 271–279 (2012). https://doi.org/10.1016/j.msea.2012.01.093

T. Jiang, J. Sun, H. Liu et al., A high performance martensitic stainless steel containing 1.5 wt% Si. Mater. Des. 125, 35–45 (2017). https://doi.org/10.1016/j.matdes.2017.03.078

R.L. Klueh, K. Ehrlich, F. Abe, Ferritic/martensitic steels: promises and problems. J. Nucl. Mater. 191–194, 116–124 (1992). https://doi.org/10.1016/S0022-3115(09)80018-4

S. Dong, P Wang, C. Dong, et al, Sorbite stainless steel (2018)

C.A.D. Rodrigues, P.L.D. Lorenzo, A. Sokolowski et al., Development of a supermartensitic stainless steel microalloyed with niobium. J. ASTM Int. (2006). https://doi.org/10.1520/jai14086

X. Ma, C. Zhang, C. Zhang et al., Microstructure and properties of sorbite stainless steel designed by “hybrid” idea. Cailiao Daobao Mater. Rep. 34, 04103–04107 (2020). https://doi.org/10.11896/cldb.18120004

X.Y. Xue, X. Zhou, Y. Shi, Y. Xiang, Ultimate shear resistance of S600E high-strength stainless steel plate girders. J. Constr. Steel Res. 179, 106535 (2021). https://doi.org/10.1016/j.jcsr.2021.106535

F. Zhou, Y. Chen, B. Young, Cold-formed high strength stainless steel cross-sections in compression considering interaction effects of constituent plate elements. J. Constr. Steel Res. 80, 32–41 (2013). https://doi.org/10.1016/j.jcsr.2012.09.004

F. Zhou, L. Li, Experimental study on hysteretic behavior of structural stainless steels under cyclic loading. J. Constr. Steel Res. 122, 94–109 (2016). https://doi.org/10.1016/j.jcsr.2016.03.006

F. Zhou, B. Young, Cold-formed high-strength stainless steel tubular sections subjected to web crippling. J. Struct. Eng. 133, 368–377 (2007). https://doi.org/10.1061/(ASCE)0733-9445(2007)133:3(368)

I. Arrayago, E. Real, L. Gardner, Description of stress-strain curves for stainless steel alloys. Mater. Des. 87, 540–552 (2015). https://doi.org/10.1016/j.matdes.2015.08.001

WO2018001097 Sorbite stainless steel. https://patentscope.wipo.int/search/en/detail.jsf?docId=WO2018001097. Accessed 5 Oct 2020

CN107557697A—A kind of sorbite stainless steel—Google Patents. https://patents.google.com/patent/CN107557697A/en. Accessed 5 Oct 2020

C. Celada-Casero, B.M. Huang, J.R. Yang, D. San-Martin, Microstructural mechanisms controlling the mechanical behaviour of ultrafine grained martensite/austenite microstructures in a metastable stainless steel. Mater. Des. 181, 107922 (2019). https://doi.org/10.1016/j.matdes.2019.107922

Y. Hou, J. Zhao, C.Q. Cheng et al., The metastable pitting corrosion of 2205 duplex stainless steel under bending deformation. J. Alloys Compd. 830, 154422 (2020). https://doi.org/10.1016/j.jallcom.2020.154422

Y. Hou, C. Cheng, T. Cao et al., Electrochemical science effects of sensitization on the metastable pitting corrosion of 304 stainless steel. Int. J. Electrochem. Sci. 13, 7095–7110 (2018). https://doi.org/10.20964/2018.07.74

L. Peguet, A. Gaugain, C. Dussart et al., Statistical study of the critical pitting temperature of 22–05 duplex stainless steel. Corros. Sci. 60, 280–283 (2012). https://doi.org/10.1016/J.CORSCI.2012.03.025

Study of the correlation between pitting corrosion and the component ratio of the dual phase in duplex stainless steel welds | Elsevier Enhanced Reader. https://reader.elsevier.com/reader/sd/pii/S0010938X13001686?token=5C499DDBFF3670CCDA3DAEBF60D0C9331158C8AFE50946729051D8F36C14B5EA677386C37C1F744C8154DFE688D370BE&originRegion=us-east-1&originCreation=20211219053149. Accessed 19 Dec 2021

S.H. Lee, H.S. Na, K.W. Lee et al., Microstructural characteristics and m23c6 precipitate behavior of the course-grained heat-affected zone of T23 steel without post-weld heat treatment. Metals. (2018). https://doi.org/10.3390/met8030170

N. Ohkubo, K. Miyakusu, Y. Uematsu, H. Kimura, Effect of alloying elements on the mechanical properties of the stable austenitic stainless steel. ISIJ Int. 34, 764–772 (1994). https://doi.org/10.2355/isijinternational.34.764

C.A.D. Rodrigues, R.M. Bandeira, B.B. Duarte et al., Effect of phosphorus content on the mechanical, microstructure and corrosion properties of supermartensitic stainless steel. Mater. Sci. Eng., A. 650, 75–83 (2016). https://doi.org/10.1016/j.msea.2015.10.013

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Khan, S., Cheng, CQ., Cao, TS. et al. Microstructure and Corrosion Properties of S400E Sorbite Stainless Steel. Metallogr. Microstruct. Anal. 11, 649–660 (2022). https://doi.org/10.1007/s13632-022-00863-w

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13632-022-00863-w