Abstract

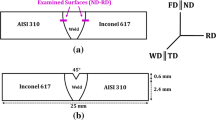

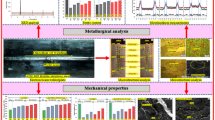

The intention in this research work is to investigate the effect of welding speed in electron beam (EB) welded 18mm thick plates of AISI 321. In this work, an attempt is made to study the effect of two different welding speeds on the microstructure, mechanical properties and corrosion resistance of the welded joints. The results in the study show that bead width, reinforcement area, dendritic length and inert dendritic spacing vary for the different heat inputs. The microstructure conducted using optical microscope and scanning electron microscope (SEM) shows the presence of lathy and vermicular ferrites in the weld bead. In addition, the ferrite measurements and the X-ray diffraction (XRD) studies indicate the difference in the ferrite content of the two beads. The fusion boundary has the highest microhardness of about 171.9 HV. The maximum toughness of 129.3J was found at the top region of the weld. The percentage elongation in the tensile test had shown increase in the root region of the welds. The rate of intergranular corrosion in mm per year was calculated and was found to be 13% more in the in the welds with more heat input.

Similar content being viewed by others

References

K. Devendranath Ramkumar, B. Pavan, V. Chandrasekar, Development of improved microstructural traits and mechanical integrity of stabilized stainless steel joints of AISI 321. J. Manuf. Process. 32, 582–594 (2018). https://doi.org/10.1016/j.jmapro.2018.03.029

A. Kumar, S.S. Sandhu, B. Singh, Effect of thermal aging on impact toughness of electron beam-welded AISI 316 stainless steel. Springer Int. Publ. (2020). https://doi.org/10.1007/978-3-030-36628-5_16

A. Kumar, B. Singh, S.S. Sandhu, Effect of thermal aging on metallurgical, tensile and impact toughness performance of electron beam welded AISI 316 SS joints. Fusion Eng. Des. 159, 111949 (2020). https://doi.org/10.1016/j.fusengdes.2020.111949

Outokumpu, Handbook of Stainless Steel, Sandvikens Tryckeri. (2013) 1–89.

B.A. Gurovich, E.A. Kuleshova, A.S. Frolov, D.A. Maltsev, K.E. Prikhodko, S.V. Fedotova, B.Z. Margolin, A.A. Sorokin, Investigation of high temperature annealing effectiveness for recovery of radiation-induced structural changes and properties of 18Cr-10Ni-Ti austenitic stainless steels. J. Nucl. Mater. (2015). https://doi.org/10.1016/j.jnucmat.2015.06.045

A. Sharma, S.S. Sandhu, V. Kumar, Assessment of mechanical and metallurgical properties of thermally aged electron beam welded AISI 321 stainless steel. Adv. Mater. Res. 1160, 93–102 (2021)

B.S.S. Yilbas, M. Sami, J. Nickel, a. Coban, S. a. M.A.M. Said, Introduction into the electron beam welding of austenitic 321-type stainless steel. J. Mater. Process. Technol. 82, 13–20 (1998). https://doi.org/10.1016/S0924-0136(97)00485-8

C.H. Hsu, T.C. Chen, R.T. Huang, L.W. Tsay, Stress corrosion cracking susceptibility of 304L Substrate and 308L weld metal exposed to a salt spray. Materials (Basel). 10, 1–14 (2017). https://doi.org/10.3390/ma10020187

A. Doomra, S.S. Sandhu, B. Singh, Effect of post weld heat treatment on metallurgical and mechanical properties of electron beam welded AISI 409 ferritic steel. Metall. Mater. Eng. 26, 279–292 (2020)

K.H. Tseng, C.P. Chou, The study of nitrogen in argon gas on the angular distortion of austenitic stainless steel weldments. J. Mater. Process. Technol. 142, 139–144 (2003). https://doi.org/10.1016/S0924-0136(03)00593-4

D.N. Wasnik, G.K. Dey, V. Kain, I. Samajdar, Precipitation stages in a 316L austenitic stainless steel. Scr. Mater. 49, 135–141 (2003). https://doi.org/10.1016/S1359-6462(03)00220-3

A. Bonakdar, M. Molavi-Zarandi, A. Chamanfar, M. Jahazi, A. Firoozrai, E. Morin, Finite element modeling of the electron beam welding of Inconel-713LC gas turbine blades. J. Manuf. Process. (2017). https://doi.org/10.1016/j.jmapro.2017.02.011

P. Sejč, R. Kubíček, Influence of heat input on the content of delta ferrite in the structure of 304L stainless steel GTA welded joints. Sci. Proc. Fac. Mech. Eng. STU Bratislava. 19, 8–14 (2012). https://doi.org/10.2478/v10228-011-0002-3

J. Singh, A.S. Shahi, Impact toughness, fatigue crack growth and corrosion behavior of thermally aged UNS S32205 duplex stainless steel. Trans. Indian Inst. Met. 72, 1497–1502 (2019). https://doi.org/10.1007/s12666-019-01574-7

T.C. Chen, H.H. Chang, J.Y. Huang, L.W. Tsay, Stress corrosion cracking of simulated heat-affected zone in a CF8A weld in high temperature water. J. Nucl. Mater. 527, 151810 (2019). https://doi.org/10.1016/j.jnucmat.2019.151810

S.S. Sandhu, A.S. Shahi, Metallurgical, wear and fatigue performance of Inconel 625 weld claddings. J. Mater. Process. Technol. 233, 1–8 (2016). https://doi.org/10.1016/j.jmatprotec.2016.02.010

S. Nakhodchi, A. Shokuhfar, S.A. Iraj, B.G. Thomas, Evolution of temperature distribution and microstructure in multipass welded AISI 321 stainless steel plates with different thicknesses. J. Press. Vessel Technol. Trans. ASME. 137, 1–15 (2015). https://doi.org/10.1115/1.4030367

M. Ali, S.K. Vadali, Development of electron beam welding procedure for Nb-1Zr-0.1C alloy, in mater. Today Proc. (2016). https://doi.org/10.1016/j.matpr.2016.09.003

M. Alali, I. Todd, B.P. Wynne, Through-thickness microstructure and mechanical properties of electron beam welded 20 mm thick AISI 316L austenitic stainless steel. Mater. Des. (2017). https://doi.org/10.1016/j.matdes.2017.05.080

S.A.A. Akbari Mousavi, A.R. Sufizadeh, Metallurgical investigations of pulsed Nd:YAG laser welding of AISI 321 and AISI 630 stainless steels. Mater. Des. 30, 3150–3157 (2009). https://doi.org/10.1016/j.matdes.2008.11.026

J. Singh, A.S. Shahi, Metallurgical and corrosion characterization of electron beam welded duplex stainless steel joints. J. Manuf. Process. 50, 581–595 (2020). https://doi.org/10.1016/j.jmapro.2020.01.009

ASTM E8, ASTM E8/E8M standard test methods for tension testing of metallic materials 1, Annu. B. ASTM Stand. 4. (2010) 1–27 https://doi.org/10.1520/E0008.

ASTM E 23-12c, Standard Test Methods for Notched Bar Impact Testing of Metallic Materials, Standards. i (2013) 1–25 https://doi.org/10.1520/E0023-12C.2.

American Society of Testing and Materials (ASTM), Standard Test Method for Microindentation Hardness of Materials - ASTM E384, ASTM Stand. 14 (2002) 1–24.

A.S. A262, Standard Practices for Detecting Susceptibility to Intergranular Attack in Austenitic Stainless Steels, ASTM Int. West Conshohocken, PS. 01 (2014) 1–17 https://doi.org/10.1520/A0262-15

S. Kumar, A.S. Shahi, Studies on metallurgical and impact toughness behavior of variably sensitized weld metal and heat affected zone of AISI 304L welds. Mater. Des. 89, 399–412 (2016). https://doi.org/10.1016/j.matdes.2015.09.145

H. Inoue, T. Koseki, S. Ohkita, M. Fuji, Formation mechanism of vermicular and lacy ferrite in austenitic stainless steel weld metals. Sci. Technol. Weld. Join. 5, 385–396 (2000). https://doi.org/10.1179/136217100101538452

C.C. Silva, H.C. De Miranda, H.B. De SantAna, J.P. Farias, Microstructure, hardness and petroleum corrosion evaluation of 316L/AWS E309MoL-16 weld metal. Mater. Charact. 60, 346–352 (2009). https://doi.org/10.1016/j.matchar.2008.09.017

J.W. Fu, Y.S. Yang, J.J. Guo, J.C. Ma, W.H. Tong, Microstructure evolution in AISI 304 stainless steel during near rapid directional solidification. Mater. Sci. Technol. 25, 1013–1016 (2009). https://doi.org/10.1179/174328408X317093

M. Tavares, V.M.E. Aline, Y. Kina, L.D.L.E.F.B. Mainier, Influence of stabilization heat treatments on microstructure hardness and intergranular corrosion resistance of the AISI 321 stainless steel. J. Mater. Sci. (2008). https://doi.org/10.1007/s10853-007-1785-5

S. Mohan Kumar, N. Siva Shanmugam, Studies on the weldability, mechanical properties and microstructural characterization of activated flux TIG welding of AISI 321 austenitic stainless steel. Mater. Res. Express. (2018). https://doi.org/10.1088/2053-1591/aad99f

M. Zhang, G. Chen, Y. Zhou, S. Liao, Optimization of deep penetration laser welding of thick stainless steel with a 10kW fiber laser. Mater. Des. (2014). https://doi.org/10.1016/j.matdes.2013.06.066

A. Kumar, B. Singh, S.S. Sandhu, Influence of thermal aging on metallurgical, mechanical and corrosion performance of electron beam welded 18 mm thick AISI 316. Fusion Eng. Des. (2020). https://doi.org/10.1016/j.fusengdes.2020.112092

H. Schroeder, W. Liu, Dependence of the tensile properties of 316 L parent material and welds on implanted hydrogen and/or helium. J. Nucl. Mater. (1992). https://doi.org/10.1016/0022-3115(92)90577-8

K.S. Guan, X.D. Xu, Y.Y. Zhang, Z.W. Wang, Cracks and precipitate phases in 321 stainless steel weld of flue gas pipe. Eng. Fail. Anal. (2005). https://doi.org/10.1016/j.engfailanal.2004.05.008

X. Xia, J. Wu, Z. Liu, X. Shen, J. Ma, Z. Liu, Study of microstructure difference properties of electron beam welds with beam oscillation of 50 mm 316L in CFETR. Fusion Eng. Des. 138, 339–346 (2019). https://doi.org/10.1016/j.fusengdes.2018.12.011

A. Pardo, M.C. Merino, A.E. Coy, F. Viejo, M. Carboneras, R. Arrabal, Influence of Ti C and N concentration on the intergranular corrosion behaviour of AISI 316Ti and 321 stainless steels. Acta Mater. 55, 2239–2251 (2007)

Acknowledgements

The authors wish to acknowledge the department of Mechanical Engineering, IKG Punjab Technical University Kapurthala, for providing the support and lab facilities.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Sharma, A., Kumar, V. & Sandhu, S.S. Effects of Welding Speed on the Microstructure, Mechanical Properties and Corrosion Resistance of the Electron Beam Welded AISI 321 Plates. Metallogr. Microstruct. Anal. 10, 184–198 (2021). https://doi.org/10.1007/s13632-021-00726-w

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13632-021-00726-w