Abstract

The phase stability of a Cu–30at.%Al milled and quenched is studied by differential scanning calorimetry and in situ high-temperature X-ray diffraction (HT-XRD). This analysis was performed from room temperature to 700 °C. The grain growth at fixed temperatures was analyzed by HT-XRD. The size of the γ2 phase grains do not change at a constant temperature with the time at temperatures below 600 °C. This behavior was attributed to the pulling force resulting from the presence of nanometric grains. The presence of nanometric grains was confirmed by TEM. The lack of grain size growth at a constant temperature is a promising result for the technological application of the Cu–30at.%Al milled and quenched as a shape memory alloy.

Similar content being viewed by others

References

K. Oishi, L.C. Brown, Stress-induced martensite formation in Cu–Al–Ni alloys. Metallurg. Trans. 2(7), 1971–1977 (1971)

A. Agrawal, R.K. Dube, Methods of fabricating Cu–Al–Ni shape memory alloy. J. Alloys Compd. 750, 235–247 (2018)

R. Dasgupta, A look into Cu-based shape memory alloys: present scenario and future prospects. J. Mater. Res. 29(16), 1681–1698 (2014)

J.L. Murray, The aluminium–copper system. Int. Metals Rev. 30(1), 211–233 (1985)

G. Roulin, P. Duval, Initial stages of ordering obtained by tempering of disorder martensitic phase of Cu–Al alloys. Scr. Mater. 37, 45–51 (1997)

Z. Nishiyama, J. Kakinoki, S. Kajiwara, Stacking faults in the martensite of Cu–Al alloy. J. Phys. Soc. Jpn. 20(7), 1192–1211 (1965)

P.R. Swann, H. Warlimont, The electron-metallography and crystallography of copper–aluminum martensites. Acta Metall. 11(6), 511–527 (1963)

S. Westman, Refinement of the γ-Cu9–Al4 structure. Acta Chem. Scand. 19, 1411–1419 (1965)

S.W. Husain, M.S. Ahmed, I. Qamar, Dendritic morphology observed in the solid-state precipitation in binary alloys. Metall. Mater. Trans. A 30(6), 1529–1534 (1999)

G.J. Arruda, A.T. Adorno, R. Magnani, C.R.S. Beatrice, Kinetics of eutectoid decomposition in Cu–Al and Cu–Al–Ag alloys. Mater. Lett. 32(2–3), 79–84 (1997)

M.L. Castro, R. Romero, Isothermal decomposition of the Cu–22.72Al–3.55Be(at.%) alloy. Mater. Sci. Eng. A 287(1), 66–71 (2000)

M.L. Castro, O. Fornaro, Formation of dendritic precipitates in the beta phase of Cu-based alloys. J. Mater. Sci. 44, 5829–5835 (2009)

V.E.A. Araujo, R. Gastien, E. Zelaya, J.I. Beiroa, I. Corro, M. Sade, F.C. Lovey, Effects on the martensitic transformations and the microstructure of CuAlNi single crystals after ageing at 473 K. J. Alloys Compd. 641, 155–161 (2015)

M.T. Ochoa-Lara, H. Flores-Zúñiga, D. Rios-Jara, Study of γ2 precipitation in Cu–Al–Be shape memory alloys. J. Mater. Sci. 41, 5455–5461 (2006)

C. Suryanarayana, Mechanical alloying and milling. Prog. Mater Sci. 46, 1–184 (2001)

S.K. Vajpai, R.K. Dube, S. Sangal, Application of rapid solidification powder metallurgy processing to prepare Cu–Al–Ni high temperature shape memory alloy strips with high strength and high ductility. Mater. Sci. Eng. A 570, 32–42 (2013)

S. Pourkhorshidi, N. Parvin, M.S. Kenevisi, M. Naeimi, H. Ebrahimnia Khaniki, A study on the microstructure and properties of Cu-based shape memory alloy produced by hot extrusion of mechanically alloyed powders. Mater. Sci. Eng. A 556, 658–663 (2012)

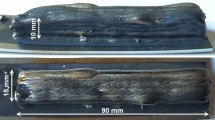

M.F. Giordana, N. Muñoz Vásquez, M.R. Esquivel, E. Zelaya, Analysis of the Cu–Al milling stages through the microstructure evolution studied by TEM and SEM. Metallogr. Microstruct. Anal. 6, 139–149 (2017)

K. Chittineni, D.G. Bhat, X-ray diffraction investigation of the formation of nanostructured metastable phases during short-duration mechanical alloying of Cu–Al powder mixtures. Mater. Manuf. Processes 21(5), 527–533 (2006)

S. Xi, J. Zhou, D. Zhang, X. Wang, Solid-state synthesis reaction between Al and Cu powders during ball milling. Mater. Lett. 26, 245–248 (1996)

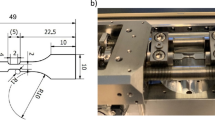

N.N. Sanchez Pascal, M.F. Giordana, F. Napolitano, M.R. Esquivel, E. Zelaya, Thermal stability analysis of Cu–11.8wt.%Al milled samples by TEM and HT-XRD. Adv. Powder Technol. 28(10), 2605–2612 (2017)

B.E. Warren, B.L. Averbach, The effect of cold-work distortion on X ray patterns. J. Appl. Phys. 21, 595–599 (1950)

B. Marinkovic, R. Riveiro de Avillez, A. Saavedra, F.C. Rizzo Assunçāo, A comparison between the Warren Averbach method and alternate methods for X-ray diffraction microstructure analysis of polycrystalline specimens. Mater. Res. 4(2), 71–76 (2001)

S.A. Speakman, Estimating crystallite size using XRD. Lecture. http://prism.mit.edu/XRAY/oldsite/CrystalSizeAnalysis.pdf

J. Kwarciak, Z. Bojajarski, H. Morawiec, Phase transformation in martensite of Cu–12.4%Al. J. Mater. Sci. 21, 788–792 (1986)

M.F. Giordana, M.R. Esquivel, E. Zelaya, A detailed study of phase evolution in Cu–16at.%Al and Cu–30at.%Al alloys under different types of mechanical alloying processes. Adv. Powder Technol. 26(2), 470–477 (2015)

X.J. Liu, I. Ohnuma, R. Kainuma, K. Ishida, Phase equilibria in the Cu–rich portion of the Cu–Al binary system. J. Alloys Compd. 264, 201–208 (1998)

H. Cheniti, M. Bouabdallah, E. Patoor, High temperature decomposition of the β1 phase in a Cu–Al–Ni shape memory alloy. J. Alloys Compd. 476, 420–424 (2009)

D.A. Porter, K.E. Easterling, Phase Transformations in Metals and Alloys (Springer, Berlin, 1992)

J. Rodriguez-Carvajal, Fullprof: a program for Rietveld refinement and pattern matching analysis, in Proceedings of Fifteenth Conference of the International Union of Crystallography, Toulouse, France, Vol. 127 (1990)

J. Rodriguez-Carvajal, Recent developments of the program FULLPROF. Comm. Powder Diffr. (IUCr) 26, 12–19 (2001)

A. Guinier, D.L. Dexter, X-ray Studies of Materials (Interscience Publishers, Geneva, 1963)

M. De Graef, Introduction to Conventional Transmission Electron Microscopy (Cambridge University Press, Cambridge, 2002)

M.M. Moshksar, H. Doty, R. Abbaschian, Grain growth in NiAl–Al2O3 in situ composites. Intermetallics 5, 393–399 (1997)

Acknowledgements

The authors thank Consejo Nacional de Investigaciones Científicas y Técnicas (CONICET), the Agencia Nacional de Promoción Científica y Tecnológica (ANPCyT: PICT-2015-1641), Comisión Nacional de Energía Atómica (CNEA) and Universidad Nacional del Comahue (UNCo: PI-B202-2017) for the financial support to this work.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Giordana, M.F., Esquivel, M.R. & Zelaya, E. The Microstructure and the Phase Stability of a Cu–30at.%Al Alloy Obtained by Reactive Milling and Quenching. Metallogr. Microstruct. Anal. 9, 816–824 (2020). https://doi.org/10.1007/s13632-020-00694-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13632-020-00694-7