Abstract

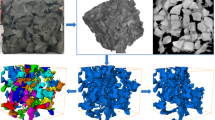

Solidification dendrites in metal alloys have intricate shapes with fractal elements, making fractal dimension an attractive potential method for more completely quantifying these important shapes. However, fractal analysis as usually applied to dendrites has some pitfalls, which we demonstrate here on micrographs of dendrites from two different aluminum–silicon alloys with different solidification velocities. Box dimension and a more rigorous analysis of correlation dimension were calculated for each sample, but both measures exhibited non-uniform scaling. Further analysis using the Takens–Theiler estimator of correlation dimension revealed a transition between two distinct scaling regimes: a small-scale exponent associated with dendrite boundary texture and the large-scale with overall dendrite morphology. The scaling transition between regimes may prove useful as an automated alternative to secondary dendrite arm spacing. Overall, the investigations give further insight into the quantitative description of complex dendritic structures and clarify the ability of fractal analysis to describe this important solidification morphology.

Similar content being viewed by others

References

U. Bisang, J.H. Bilgram, The fractal dimension of xenon dendrites. J. Cryst. Growth 166(1–4), 207–211 (1996). https://doi.org/10.1016/0022-0248(96)00049-8

K. Ohsasa, Evaluation of dendritic morphology using fractal dimension and dimensionless perimeter in unidirectionally solidified Al–Si alloys. IOP Conf. Ser. Mater. Sci. Eng. 1, 12–33 (2015)

A.L. Genau, A.C. Freedman, L. Ratke, Effect of solidification conditions on fractal dimension of dendrites. J. Cryst. Growth 363, 49–54 (2013). https://doi.org/10.1016/j.jcrysgro.2012.09.044

Y. Couder, F. Argoul, A. Arneodo, J. Maurer, M. Rabaud, Statistical properties of fractal dendrites and anisotropic diffusion-limited aggregates. Phys. Rev. A 42(6), 3499 (1990)

C. Dominkovics, G. Harsanyi, Dendrite material identification method using fractal analysis, in 33rd International Spring Seminar on Electronics Technology, ISSE 2010 (2010)

B. Mandelbrot, How long is the coast of Britain? Statistical self-similarity and fractional dimension. Science 156(3775), 636–638 (1967)

F. Takens, On the numerical determination of the dimension of an attractor, in Dynamical Systems and Bifurcations, ed. by B. Braaksma, H. Braer, F. Takens (Springer, New York, 1985), pp. 99–106

J. Theiler, Estimating fractal dimension. J. Opt. Soc. Am. A 7(6), 1055 (1990). https://doi.org/10.1364/josaa.7.001055

G. Gonzato, F. Mulargia, W. Marzocchi, Practical application of fractal analysis: problems and solutions. Geophys. J. Int. 132(2), 275–282 (1998). https://doi.org/10.1046/j.1365-246x.1998.00461.x

B.J. West, Nature’s Patterns and the Fractional Calculus, 2nd edn. (De Gruyter, Berlin, 2017)

J. Alkemper, S. Sous, C. Stöcker, L. Ratke, Directional solidification in an aerogel furnace with high resolution optical temperature measurements. J. Cryst. Growth 191, 252–260 (1998). https://doi.org/10.1016/S0022-0248(98)00114-6

N. Otsu, A threshold selection method from gray-level histograms. IEEE Trans. Syst. Man Cybern. 9(1), 62–66 (1979)

T. MathWorks, MATLAB and Image Processing Toolbox. Release 2016b, Natick, MA, USA

M.C. Flemings, T.Z. Kattamis, B.P. Bardes, Dendrite arm spacing in aluminium alloys. Trans. Am. Foundry Soc. 99, 501–506 (1991)

D. Bouchard, J.S. Kirkaldy, Prediction of dendrite arm spacings in unsteady- and steady-state heat flow of unidirectionally solidified binary alloys. Metall. Mater. Trans. B 28(4), 1997 (1997). https://doi.org/10.1007/s11663-997-0039-x

T. Okamoto, K. Kishitake, Dendritic structure in unidirectionally solidified aluminum, tin, and zinc base binary alloys. J. Cryst. Growth 29(2), 137–146 (1975). https://doi.org/10.1016/0022-0248(75)90217-1

M.D. Peres, C.A. Siqueira, A. Garcia, Macrostructural and microstructural development in Al–Si alloys directionally solidified under unsteady-state conditions. J. Alloys Compd. 381, 168–181 (2004). https://doi.org/10.1016/j.jallcom.2004.03.107

Acknowledgements

Al–Si samples were originally created by Sonja Steinbach and Lorenz Ratke in the Institute for Materials Physics in Space at German Aerospace Centre (DLR) in Cologne.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Warriner, W.E., Friess, J. & Genau, A. Fractal Correlation Dimensions Analysis of Al–Si Dendrites. Metallogr. Microstruct. Anal. 9, 561–569 (2020). https://doi.org/10.1007/s13632-020-00672-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13632-020-00672-z