Abstract

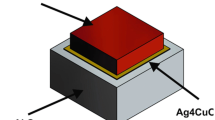

The growth of inventive high-temperature electrochemical devices such as solid oxide fuel cells constitutes a major task in brazing technology of ceramic–metal joints. In this work, reactive air brazing was used and the joining characteristics of 3YSZ with Crofer 22 APU have been systematically analyzed for three different brazing temperatures (1000, 1050 and 1100 °C) and two dwell times (5 and 30 min). The joints have been brazed successfully using the Ag–4CuO filler alloy. This braze filler metal was manufactured by an arc PVD (physical vapor deposition) process. Further, sufficient wetting of the zirconium oxide was achieved. The morphology of the oxide reaction layer at the steel side had a major influence on the shear strength of the brazed joints. A maximum average shear strength of 101 ± 4 MPa was obtained for a temperature of 1050 °C and a dwell time of 5 min.

Similar content being viewed by others

References

B. Kuhn, Bruchmechanische Untersuchung von Metall-Keramik-Verbundsystemen für die Anwendung in der Hochtemperaturbrennstoffzelle (SOFC). PhD Thesis, Technical University Clausthal (2009)

C. Li, Mechanical behavior and microstructure of reactive-air-brazed metal/ceramic joints. PhD Thesis, RWTH-Aachen University (2013)

S. Zügner, Nickelreaktivlot, Oxidkeramik-Fügungen als elektrisch isolierende Dichtungskonzepte für Hochtemperatur-Brennstoffzellen-Stacks. PhD Thesis, Bochum University (2008)

M. Stanislowski, Verdampfung von Werkstoffen beim Betrieb von Hochtemperaturbrennstoffzellen (SOFC). PhD Thesis, RWTH-Aachen University (2006)

B. Kuhn, F.J. Wetzel, J. Malzbender, R.W. Steinbrech, L. Singheiser, Mechanical performance of reactive-air-brazed (RAB) ceramic/metal joints for solid oxide fuel cells at ambient temperature. J. Power Sources 193, 199–202 (2009)

J. Brandenberg, B. Kuhn, M. Pausch, Dual-gas stability of RAB-joints in SOFC applications. Adv. Eng. Mater. 16, 1415–1422 (2014)

P. Lamp, J. Tachtler, O. Finkenwirth, S. Mukerjee, S. Shaffer, Development of an auxiliary power unit with solid oxide fuel cells for automotive applications. Fuel Cells 3, 146–152 (2003)

B. Kuhn, E. Wessel, J. Malzbender, R.W. Steinbrech, L. Singheiser, Effect of isothermal aging on the mechanical performance of brazed ceramic/metal joints for planar SOFC-stacks. Int. J. Hydrogen Energy 35, 9158–9165 (2010)

E. Skiera, J. Brandenberg, C. Li, T. Beck, L. Singheiser, B. Kuhn, Mechanical properties of reactive air brazed (RAB) metal/ceramicjJoints. Part 1: Visco-plastic deformation of silver-based reactive air brazes. Adv. Eng. Mater. 16, 1462–1467 (2014)

K. Bobzin, T. Schlaefer, L. Zhao, N. Kopp, A. Schlegel, Brazing of ceramic-to-ceramic and ceramic-to-metal joints in air. Front. Mech. Eng. China 5, 125–129 (2010)

J.W. Fergus, Metallic interconnects for solid oxide fuel cells. Mater. Sci. Eng., A 397, 271–283 (2005)

T. Brylewski, Application of Fe–16Cr ferritic alloy to interconnector for a solid oxide fuel cell. Solid State Ion. 143, 131–150 (2001)

K. Przybylski, T. Brylewski, E. Durda, R. Gawel, A. Kruk, Oxidation properties of the Crofer 22 APU steel coated with La0.6Sr0.4Co0.2Fe0.8O3 for IT-SOFC interconnect applications. J. Therm. Anal. Calorim. 116, 825–834 (2014)

T. Brylewski, J. Dąbek, K. Przybylski, Oxidation kinetics study of the iron-based steel for solid oxide fuel cell application. J. Therm. Anal. Calorim. 77, 207–216 (2004)

A. Okada, Ceramic technologies for automotive industry: current status and perspectives. Mater. Sci. Eng., B 161, 182–187 (2009)

T. Ishihara, Oxide ion-conducting materials for electrolytes, in Materials for High-Temperature Fuel Cells, ed. by S.P. Jiang, Y. Yan (Wiley-VCH, Hoboken, 2013), pp. 97–132

S. Sirohi, S. Kumar, C. Pandey, Characterization of damage in thermal barrier coating under different thermal cycle, in Materials Today: Proceedings (2020)

J.G. Thakare, C. Pandey, M.M. Mahapatra, R.S. Mulik, Thermal Barrier Coatings—A State of the Art Review, Met. Mater. Int. (2020). https://doi.org/10.1007/s12540-020-00705-w

J.G. Thakare, C. Pandey, R.S. Mulik, M.M. Mahapatra, Microstructure and mechanical properties of D-Gun sprayed Cr3C2-NiCr coating on P91 steel subjected to long term thermal exposure at 650 °C. Mater. Res. Express 6, 1165h1 (2019)

J.G. Thakare, C. Pandey, R.S. Mulik, M.M. Mahapatra, Mechanical property evaluation of carbon nanotubes reinforced plasma sprayed YSZ-alumina composite coating. Ceram. Int. 44, 6980–6989 (2018)

V. Schuler, J. Twrdek, Praxiswissen Schweißtechnik. Werkstoffe, Prozesse, Fertigung, 6., vollständig überarbeitete Auflage (Springer, 2019)

J.A. Fernie, R.A.L. Drew, K.M. Knowles, Joining of engineering ceramics. Int. Mater. Rev. 54, 283–331 (2009)

W. Tillmann, Aspekte des Aktivlötens nichtoxidischer Ingenieurskeramiken. PhD Thesis, RWTH-Aachen University (1992)

Y. Zhao, J. Malzbender, S.M. Gross, The effect of room temperature and high temperature exposure on the elastic modulus, hardness and fracture toughness of glass ceramic sealants for solid oxide fuel cells. J. Eur. Ceram. Soc. 31, 541–548 (2011)

J.Y. Kim, J.S. Hardy, K.S. Weil, Dual-atmosphere tolerance of Ag–CuO-based air braze. Int. J. Hydrogen Energy 32, 3655–3663 (2007)

M.G. Nicolas, Reactive wetting and brazing of ceramics, in: Proceedings of the 4th International Conference Joining Ceramics, Glass and Metal, S. pp. 57–67. (1993)

R.M.D. Nascimento, A.E. Martinelli, A.J.A. Buschinelli, Review article: recent advances in metal-ceramic brazing. Cerâmica 49, 178–198 (2003)

M. Boretius, E. Lugscheider, W. Tillmann, Fügen von Hochleistungskeramik: Verfahren, Auslesung, Prüfung (Anwendung. VDI-Verlag, Düsseldorf, 1995)

K.S. Weil, J.Y. Kim, J.S. Hardy, Reactive air brazing. A novel method of sealing SOFCs and other solid-state electrochemical devices. Electrochem. Solid-State Lett. 8, A133 (2005)

K.S. Weil, J.Y. Kim, J.S. Hardy, Development of Brazing Technology for Use in High-Temperature Gas Separation Equipment, in 17th Annual Conference on Fossil Energy Materials, Baltimore, Maryland (2003)

N. Kopp, Reactive air brazing, Löten von Keramik-Keramik- und Keramik-Metall-Verbunden an Luft. PhD Thesis, RWTH-Aachen University (2012)

J. Ovenstone, J.-I. Jung, J.S. White, D.D. Edwards, S.T. Misture, Phase stability of BSCF in low oxygen partial pressures. J. Solid State Chem. 181, 576–586 (2008)

K. Weil, J. Hardy, J. Rice, J. Kim, Brazing as a means of sealing ceramic membranes for use in advanced coal gasification processes. Fuel 85, 156–162 (2006)

K.S. Weil, C.A. Coyle, J.T. Darsell, G.G. Xia, J.S. Hardy, Effects of thermal cycling and thermal aging on the hermeticity and strength of silver–copper oxide air-brazed seals. J. Power Sources 152, 97–104 (2005)

K.S. Weil, J.P. Rice, Substrate effects on the high-temperature oxidation behavior of a gold-based braze filler metal. Scr. Mater. 52, 1081–1085 (2005)

J.Y. Kim, J.S. Hardy, K.S. Weil, Silver-copper oxide based reactive air braze for joining yttria-stabilized zirconia. J. Mater. Res. 20, 636–643 (2005)

J.Y. Kim, J.S. Hardy, K.S. Weil, Effects of CuO content on the wetting behavior and mechanical properties of a Ag–CuO braze for ceramic joining. J. Am. Ceram. Soc. 88, 2521–2527 (2005)

K.S. Weil, J.Y. Kim, J.S. Hardy, J.T. Darsell, The effect of TiO2 on the wetting behavior of silver–copper oxide braze filler metals. Scr. Mater. 54, 1071–1075 (2006)

K. Bobzin, M. Öte, S. Wiesner, A. Kaletsch, C. Broeckmann, Characterization of reactive air brazed ceramic–metal joints with unadapted thermal expansion behavior. Adv. Eng. Mater. 16, 1490–1497 (2014)

J.S. Hardy, J.Y. Kim, E.C. Thomsen, K.S. Weil, Improved wetting of mixed ionic/electronic conductors used in electrochemical devices with ternary air braze filler metals. J. Electrochem. Soc. 154, P32 (2007)

E.J. Pavlina, A.M. Meier, P. Monteleone, J.D. Weigner, Development of silver–metal oxide reactive air braze alloys for electroding PZT ceramics. J. Mater. Sci. 42, 705–713 (2007)

J. Kim, J. Hardy, K. Weil, Ag–Al based air braze for high temperature electrochemical devices. Int. J. Hydrogen Energy 32, 3754–3762 (2007)

S.W. Sofie, P. Gannon, V. Gorokhovsky, Silver–chromium oxide interactions in SOFC environments. J. Power Sources 191, 465–472 (2009)

K. Bobzin, T. Schläfer, N. Kopp, Thermochemistry of brazing ceramics and metals in air. Int. J. Mater. Res. 102, 972–976 (2011)

H. Chen, L. Li, R. Kemps, B. Michielsen, M. Jacobs, F. Snijkers, V. Middelkoop, Reactive air brazing for sealing mixed ionic electronic conducting hollow fibre membranes. Acta Mater. 88, 74–82 (2015)

W. Tillmann, N. Sievers, J. Pfeiffer, L. Wojarski, R. Zielke, A. Poenicke, J. Schilm, Examination of the porosity in reactive air brazed joints by ultrasonic testing. Adv. Eng. Mater. 16, 1437–1441 (2014)

ThyssenKupp VDM-Metals GmbH, “VDM® Crofer 22 APU”, data sheet, received: 31.03.2020, 09:41 GMT + 1

J.T. Darsell, K.S. Weil, Effect of Pd additions on the invariant reactions in the Ag − CuOx system. J. Phase Equilib. Diffus. 27, 92–101 (2006)

S. Reichle, Alternative approaches and further developments of reactive air brazing of metal-ceramic joints for the use in solid oxide fuel cell. PhD Thesis, RWTH-Aachen University (2017)

A. Elrefaey, W. Tillmann, Evaluation of transient liquid phase bonding between titanium and steel. Adv. Eng. Mater. 11, 556–560 (2009)

K. Möhwald, Einsatz des Ionenplattierens beim Löten. PhD Thesis, University Dortmund (1996)

L. Wojarski, Diffusionsfügeprozesse zur Herstellung von Aluminium-Stahl-Hybridstrukturen unter Verwendung der PVD-Beschichtung. PhD Thesis, TU Dortmund (2019)

W. Tillmann, N.B. Anar, L. Wojarski, Mechanical behavior of reactive air brazed (RAB) Crofer 22 APU-Al2O3 joints at ambient temperature. SN Appl. Sci. 2, 1–12 (2020)

Z.B. Shao, K.R. Liu, L.Q. Liu, H.K. Liu, S.-X. Dou, Equilibrium phase diagrams in the systems PbO–Ag and CuO–Ag. J. Am. Ceram. Soc. 76, 2663–2664 (1993)

A. Pönicke, Löten von Keramik-Metall-Verbunden mit Reaktivloten an Luft und deren Alterungsverhalten bei hohen Temperaturen. PhD Thesis, Technical University Dresden (2014)

N.J. Magdefrau, L. Chen, E.Y. Sun, M. Aindow, Effects of alloy heat treatment on oxidation kinetics and scale morphology for Crofer 22 APU. J. Power Sources 241, 756–767 (2013)

J.Y. Kim, K.S. Weil, J.S. Hardy, Wetting and mechanical characteristics of the reactive air braze for yttria-stabilized zirconia (YSZ) joining, in Surfaces, Interfaces, and the Science of Ceramic Joining, ed. by K.S. Weil, I.E. Reimanis, C.A. Lewinsohn (Wiley, Hoboken, 2006), pp. 101–109

C. Li, B. Kuhn, J. Brandenberg, T. Beck, L. Singheiser, K. Bobzin, N. Bagcivan, N. Kopp, Improving contour accuracy and strength of reactive air brazed (RAB) ceramic/metal joints by controlling interface microstructure. Adv. Eng. Mater. 14, 394–399 (2012)

Acknowledgements

The authors gratefully acknowledge the financial support of the German Research Foundation (DFG) within the Project TI 343/147-1 (In situ investigation of the pore development during reactive air brazing of aluminum oxide ceramics).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Tillmann, W., Anar, N.B., Wojarski, L. et al. Microstructure and Mechanical Properties of Reactive-Air-Brazed 3YSZ/Crofer 22 APU Joints at Ambient Temperature. Metallogr. Microstruct. Anal. 9, 529–540 (2020). https://doi.org/10.1007/s13632-020-00663-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13632-020-00663-0