Abstract

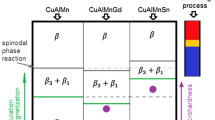

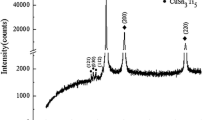

The effects of Sn or Gd additions on the microstructure and phases transitions of the Cu–11%Al alloy (composition in wt.) were studied by Vickers microhardness measurements as a function of quenching temperature, optical microscopy (OM), scanning electronic microscopy (SEM), energy-dispersive X-ray spectroscopy (EDS), X-ray diffraction (XRD), and differential scanning calorimetry (DSC). The results showed that the addition of Sn stabilizes the \( \beta \) phases, whereas the addition of Gd modifies the alloy microstructure, but it does not significantly interfere on the phase transitions observed in the Cu–11%Al alloy.

Similar content being viewed by others

Change history

27 November 2019

The original version of this article was updated to center (wt.%) in the table headings.

References

H.H. Kuo, W.H. Wang, Y.F. Hsu, C.A. Huang, The corrosion behavior of Cu–Al and Cu–Al–Be shape-memory alloys in 0.5 M H2SO4 solution. Corros. Sci. 48, 4352–4364 (2006). https://doi.org/10.1016/j.corsci.2006.04.006

M.A. Shaik, K.H. Syed, B.R. Golla, Electrochemical behavior of mechanically alloyed hard Cu–Al alloys in marine environment. Corros. Sci. 153, 249–257 (2019). https://doi.org/10.1016/j.corsci.2019.03.043

S. Montecinos, S. Simison, Corrosion behavior of Cu–Al–Be shape memory alloys with different compositions and microstructures. Corros. Sci. 74, 387–395 (2013). https://doi.org/10.1016/j.corsci.2013.05.012

M.A. Haidar, S.N. Saud, E. Hamzah, Microstructure, mechanical properties, and shape memory effect of annealed Cu–Al–Ni–xCo shape memory alloys. Metallogr. Microstruct. Anal. 7, 57–64 (2017). https://doi.org/10.1007/s13632-017-0413-2

J.P. Oliveira, B. Crispim, Z. Zeng, T. Omori, F.M. Braz Fernande, R.M. Miranda, Microstructure and mechanical properties of gas tungsten arc welded Cu–Al–Mn shape memory alloy rods. J. Mater. Process. Technol. 271, 93–100 (2019). https://doi.org/10.1016/j.jmatprotec.2019.03.020

M.F. Shuwadi, S.N. Saud, E. Hamzah, Deformation influences on microstructure, mechanical properties, and shape memory behavior of Cu–Al–Ni–xTi shape memory alloys. Metallogr. Microstruct. Anal. 8, 406–414 (2019). https://doi.org/10.1007/s13632-019-00526-3

A. Agrawala, R. Kumar Dube, Methods of fabricating Cu–Al–Ni shape memory alloys. J. Alloys Compd. 750, 235–247 (2018). https://doi.org/10.1016/j.jallcom.2018.03.390

J.L. Murray, The aluminium–copper system. Int. Met. 30, 211–233 (1985)

J.R. Davis, ASM Speciality Handbook: Copper and Copper Alloys (ASM International, Cleveland, 2001)

G.F. Brazolin, C. Aksu Canbay, S. Ozgen, A.B. Oliveira, R.A.G. Silva, Effects of Gd addition on the thermal and microstructural behaviors of the as-cast Cu–9%Al and Cu–9%Al–10%Mn alloys. Appl. Phys. A 122, 928 (2016). https://doi.org/10.1007/s00339-016-0474-0

G.F. Brazolin, C.C.S. Silva, L.S. Silva, R.A.G. Silva, Phase transformations in an annealed Cu–9Al–10Mn–3Gd alloy. J. Therm. Anal. Calorim. (2018). https://doi.org/10.1007/s10973-018-7586-z

A.B. Oliveira, R.A.G. Silva, Thermomagnetic behavior of an as-quenched Cu–Al–Mn–Gd alloy. Mater. Chem. Phys. 209, 112–120 (2018). https://doi.org/10.1016/j.matchemphys.2018.01.072

A.B. Oliveira, A. Paganotti, R.A.G. Silva, Kinetics of martensite decomposition in a Gd-modified Cu–Al alloy. J. Phys. Chem. Solids (2019). https://doi.org/10.1016/j.jpcs.2019.109074

S.L. Leach, G.V. Raynor, The constitution of the copper-rich copper–aluminium–tin alloys, with special reference to ternary compound formation, W. Hume-Rothery. Proc. R. Soc. Lond. Ser. A Math. Phys. Sci. 12, 251–259 (1954)

D.F. Soares, M. Abreu, D. Barros, F. Castro, Experimental study of the Cu–Al–Sn phase equilibria, close to the copper zone. J. Min. Met. Sect. B Metall. 53, 209–213 (2017). https://doi.org/10.2298/JMMB170515034S

A.K. Chakrabarty, K.T. Jacob, Isothermal transformation of β-phase in Cu-rich Cu–Al–Sn alloys. Int. J. Mater. Res. 104, 430–444 (2013). https://doi.org/10.3139/146.110881

J. Miettinen, Thermodynamic description of the Cu–Al–Sn system in the copper-rich corner. Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 33A, 1639–1648 (2002). https://doi.org/10.1007/s11661-002-0173-7

A.G. Magdalena, A.T. Adorno, T.M. Carvalho, R.A.G. Silva, β phase transformations in the Cu-11mass % Al alloy with Ag additions. J. Therm. Anal. Calorim. 106, 339–342 (2011). https://doi.org/10.1007/s10973-011-1432-x

R.A.G. Silva, A. Paganotti, S. Gama, A.T. Adorno, T.M. Carvalho, C.M.A. Santos, Investigation of thermal, mechanical and magnetic behaviors of the Cu–11%Al alloy with Ag and Mn additions. Mater. Charact. 75, 194–199 (2013). https://doi.org/10.1016/j.matchar.2012.11.007

A.T. Adorno, T.M. Carvalho, A.G. Magdalena, C.M.A. Santos, R.A.G. Silva, Activation energy for the reverse eutectoid reaction in hypo-eutectoid Cu–Al alloys. Thermochim. Acta 531, 35–41 (2012). https://doi.org/10.1016/j.tca.2011.12.027

L.B. McCusker, R.B. Von Dreele, D.E. Cox, D. Louer, P. Scardi, Rietveld refinement guidelines. J. Appl. Crystallogr. 32, 36–50 (1999). https://doi.org/10.1107/S0021889898009856

D. Balzar, N.C. Popa, Analyzing microstructure by Rietveld refinement *. Rigaku J. 22, 16–25 (2005)

A.A. Coelho, J. Evans, I. Evans, A. Kern, S. Parsons, The TOPAS symbolic computation system. Powder Diffr. S 26, S22–S25 (2011). https://doi.org/10.1154/1.3661087

B.H. Toby, R factors in Rietveld analysis: how good is good enough? Powder Diffr. 21, 67–70 (2006). https://doi.org/10.1154/1.2179804

S. Holgersson, X-ray investigation of alloys. Ann. Der Phys. 4, 35–54 (1926). https://doi.org/10.1002/andp.19263840103

J.S. Llewelyn Leach, On the structure of a phase formed in copper-aluminum alloys at low temperatures. J. Inst. Met. 92, 93–94 (1964)

A.J. Bradley, P. Jones, An X-ray investigation of the copper-aluminium alloys, J. Inst. Met. 625, 131–162 (1933)

G. Kurdjumov, V. Mireckij, T. Stelleckaja, Transformations in eutectoid alloys of Cu - Al. V. Structure of the martensitic phase gamma’ and the mechanism of the beta1 - gamma’ transformation. Zhurnal Tekhnicheskoi Fiz. 8, 1959–1972 (1938)

K.H. Buschow, A.S. Van der Goot, Composition and crystal structure of hexagonal Cu-rich rare earth - copper compounds. Acta Crystallogr. B. 27 1085–1088 (1971). https://doi.org/10.1107/S0567740871003558

N. Hoang Luong, J.J.M. Franse, T. Duc Hien, Specific heat and thermal expansion in GdxY1-xCu2. J. Phys. F. 15, 1751–1763 (1985). https://doi.org/10.1088/0305-4608/15/8/014

H. Kwarciak, J. Bojarski, Z. Morawiec, Phase transformation in martensite of Cu-12.4% Al. J. Mater. Sci. 21, 788–792 (1986). https://doi.org/10.1007/BF01117355

I. Tarora, The transformation process of β-phase of Cu-Al system and the effect of Mn addition upon it (fouth report). J. Japan Inst. Met. 13, 13–18 (1979). https://doi.org/10.2320/jinstmet1937.13.3_13

H. Hendus, H. Knoedler, Die Überstruktur der gamma-Hoch temperature phase in System Kupfer-Zinn. Acta Crystallogr. 9, 1036 (1956). https://doi.org/10.1107/S0365110X56002990

V.T. Deshpande, D.B. Sirdeshmukh, Thermal expansion of tetragonal tin. Acta Crystallogr. 14, 355–356 (1961). https://doi.org/10.1107/S0365110X61001212

D. Hull, T.W. Clyne, An Introduction to Composite Materials, 2nd edn. (Cambridge University Press, Cambridge, 1996)

Acknowledgements

This study was financed in part by the Coordenação de Aperfeiçoamento de Pessoal de Nível Superior—Brasil (CAPES)—Finance Code 001. The authors thank FAPESP (2012/050570-5 and 2019/06717-0) and CNPq for financial support.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Souza, J.S., Silva, R.A.G. Microstructure Evolution and Phase Transitions of the Annealed Cu–11%Al Alloy with Sn and Gd Additions. Metallogr. Microstruct. Anal. 8, 782–794 (2019). https://doi.org/10.1007/s13632-019-00586-5

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13632-019-00586-5