Abstract

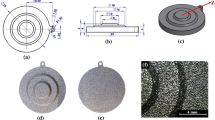

Additive manufactured selective laser melting (AM-SLM) parts often need post-printing coatings. The current research presents a method for surface finishing of AM-SLM AlSi10Mg parts coated by electroless silver plating. Such coating can be applied as a decorative film on printed replicas of antique artifacts. For this purpose, silver was deposited for the first time on AlSi10Mg printed disk-shaped specimens and coins, making their appearance close to the original artifact. The silver was plated with and without adhesion-promoting silane self-assembled monolayers. Dimensions and mass measurements, pilling test, light microscopy, optical profilometer, SEM–EDS examination, XRD analysis, and FIB-SEM technique were applied to characterize the coated samples. The results displayed good silver quality with a satisfactory appearance. The roughness of the plated samples was slightly reduced as the thickness of the silver layer was increased. The developed coating can be adapted for different applications, including printed replicas of coins in museum exhibitions.

Similar content being viewed by others

References

C.Y. Yap, C.K. Chua, Z.L. Dong, Z.H. Liu, D.Q. Zhang, L.E. Loh, S.L. Sing, Review of selective laser melting: materials and applications. Appl. Phys. Rev. 2(4), 041101–041121 (2015)

J.H. Martin, B.D. Yahata, J.M. Hundley, J.A. Mayer, T.A. Schaedler, T.M. Pollock, 3D printing of high-strength aluminium alloys. Nature 549, 365–369 (2017)

P.K. Gokuldoss, S. Kolla, J. Eckert, Additive manufacturing processes: selective laser melting, electron beam melting and binder jetting—selection guidelines. Materials 10(6), 672–674 (2017)

T.D. Ngo, A. Kashani, G. Imbalzano, K.T. Nguyen, D. Hui, Additive manufacturing (3D printing): a review of materials, methods, applications and challenges. Compos. Part B Eng. 143, 172–196 (2018)

A. Deshpande, K. Hsu, Acoustoplastic metal direct-write: towards solid aluminum 3D printing in ambient conditions. Addit. Manuf. 19, 73–80 (2018)

L. Hitzler, M. Merkel, W. Hall, A. Öchsner, A review of metal fabricated with laser-and powder-bed based additive manufacturing techniques: process, nomenclature, materials, achievable properties, and its utilization in the medical sector. Adv. Eng. Mater. 20(5), 1700658 (2018)

T. DebRoy, H.L. Wei, J.S. Zuback, T. Mukherjee, J.W. Elmer, J.O. Milewski, A.M. Beese, A. Wilson-Heid, A. De, W. Zhang, Additive manufacturing of metallic components–process, structure and properties. Prog. Mater. Sci. 92, 112–224 (2017)

S.K. Everton, M. Hirsch, P. Stravroulakis, R.K. Leach, A.T. Clare, Review of in situ process monitoring and in situ metrology for metal additive manufacturing. Mater. Des. 95, 431–445 (2016)

I. Rosenthal, A. Stern, N. Frage, Microstructure and mechanical properties of AlSi10Mg parts produced by the laser beam additive manufacturing (AM) technology. Metallogr. Microstruct. Anal. 3(6), 448–453 (2014)

I. Rosenthal, A. Stern, N. Frage, Strain rate sensitivity and fracture mechanism of AlSi10Mg parts produced by selective laser melting. Mater. Sci. Eng. A 682, 509–517 (2017)

M. Nahmany, A. Stern, E. Aghion, N. Frage, Structural properties of EB-welded AlSi10Mg thin-walled pressure vessels produced by AM-SLM technology. J. Mater. Eng. Perform. 26(10), 4813–4821 (2017)

N. Takata, H. Kodaira, K. Sekizawa, A. Suzuki, M. Kobashi, Change in microstructure of selectively laser melted AlSi10Mg alloy with heat treatments. Mater. Sci. Eng. A 704, 218–228 (2017)

D. Dai, D. Gu, H. Zhang, J. Xiong, C. Ma, C. Hong, R. Poprawe, Influence of scan strategy and molten pool configuration on microstructures and tensile properties of selective laser melting additive manufactured aluminum-based parts. Opt. Laser Technol. 99, 91–100 (2018)

A.H. Maamoun, M. Elbestawi, G.K. Dosbaeva, S.C. Veldhuis, Thermal post-processing of AlSi10Mg parts produced by selective laser melting using recycled powder. Addit. Manuf. 21, 234–247 (2018)

D. Dai, D. Gu, R. Poprawe, M. Xia, Influence of additive multilayer feature on thermodynamics, stress and microstructure development during laser 3D-printing of aluminum-based material. Sci. Bull. 62(11), 779–787 (2017)

M. Fousová, D. Dvorský, A. Michalcová, D. Vojtěch, Changes in the microstructure and mechanical properties of additively manufactured AlSi10Mg alloy after exposure to elevated temperatures. Mater. Charact. 137, 119–126 (2018)

D. Ashkenazi, How aluminum changed the world: a metallurgical revolution through technological and cultural perspectives. Technol. Forecast. Soc. Change 143, 101–113 (2019)

L. Girelli, M. Tocci, L. Montesano, M. Gelfi, A. Pola, Optimization of heat treatment parameters for additive manufacturing and gravity casting AlSi10Mg alloy, in IOP Conference Series (IOP Publishing), Mater. Sci. Eng. 264(1), 012016-1–012016-8 (2017)

I. Rosenthal, R. Shneck, A. Stern, Heat treatment effect on the mechanical properties and fracture mechanism in AlSi10Mg fabricated by additive manufacturing selective laser melting process. Mater. Sci. Eng. A 729, 310–322 (2018)

M. Tang, P.C. Pistorius, Anisotropic mechanical behavior of AlSi10Mg parts produced by selective laser melting. JOM 69(3), 516–522 (2017)

O.A. Peverini, M. Lumia, F. Calignano, G. Addamo, M. Lorusso, E.P. Ambrosio, D. Manfredi, G. Virone, Selective laser melting manufacturing of microwave waveguide devices. Proc. IEEE 105(4), 620–631 (2017)

C.C. Kuo, C.W. Wang, Y.F. Lee, Y.L. Liu, Q.Y. Qiu, A surface quality improvement apparatus for ABS parts fabricated by additive manufacturing. Int. J. Adv. Manuf. Technol. 89(1–4), 635–642 (2017)

Q. Han, H. Gu, S. Soe, R. Setchi, F. Lacan, J. Hill, Manufacturability of AlSi10Mg overhang structures fabricated by laser powder bed fusion. Mater. Des. 160, 1080–1095 (2018)

B. Whip, L. Sheridan, J. Gockel, The effect of primary processing parameters on surface roughness in laser powder bed additive manufacturing. Int. J. Adv. Manuf. Technol. 103(9–12), 1–12 (2019)

T.J. Connor, W.R. Wilson, Performance of electrical joints utilizing new silver coating on aluminum conductors. Trans. Am. Inst. Electr. Eng. Part III 72(4), 702–712 (1953)

A. Inberg, P. Livshits, Z. Zalevsky, Y. Shacham-Diamand, Electroless deposition of silver thin films on gold nanoparticles catalyst for micro and nanoelectronics applications. Microelectron. Eng. 98, 570–573 (2012)

A. Inberg, Y. Shacham-Diamand, E. Rabinovich, G. Golan, N. Croitoru, Electroless-deposited Ag–W films for microelectronics applications. Thin Solid Films 389, 213–218 (2001)

T. Asher, A. Inberg, E. Glickman, N. Fishelson, Y. Shacham-Diamand, Formation and characterization of low resistivity sub-100 nm copper films deposited by electroless on SAM. Electrochim. Acta 54(25), 6053–6057 (2009)

A. Duhin, A. Inberg, N. Eliaz, E. Gileadi, Electroless plating of rhenium-based alloys with nickel, cobalt and iron. Electrochim. Acta 174, 660–666 (2015)

M. Paunovic, Electrochemical aspects of electroless deposition of metals. Plating 55, 1161–1167 (1968)

I.C. Estrada-Raygoza, M. Sotelo-Lerma, R. Ramírez-Bon, Structural and morphological characterization of chemically deposited silver films. J. Phys. Chem. Solids 67, 782–788 (2006)

N. Fishelson, A. Inberg, N. Croitoru, Y. Shacham-Diamand, Highly corrosion resistant bright silver metallization deposited from a neutral cyanide-free solution. Microelectron. Eng. 92, 126–129 (2012)

S. Shukla, N. Gomathi, R. George, Autocatalytic silver-plating of aluminum radio frequency waveguides with autocatalytic nickel as the undercoat for space applications. Surf. Topogr. Metrol. Prop. 2(4), 045004 (2014)

D. Ashkenazi, H. Gitler, A. Stern, O. Tal, Metallurgical investigation on fourth century BCE silver jewellery of two hoards from Samaria. Sci. Rep. 7(40659), 1–14 (2017)

Y. Suematsu, K. Saito, M. Koyama, Y. Enokida, Y. Okura, T. Nakayasu, T. Sukegawa, Development of micro-mirror slicer integral field unit for space-borne solar spectrographs. CEAS Space J. 9(4), 421–431 (2017)

S. Olivera, H.B. Muralidhara, K. Venkatesh, K. Gopalakrishna, C.S. Vivek, Plating on acrylonitrile–butadiene–styrene (ABS) plastic: a review. J. Mater. Sci. 51(8), 3657–3674 (2016)

Y. Shacham-Diamand, A. Inberg, Y. Sverdlov, N. Croitoru, Electroless silver and silver with tungsten thin films for microelectronics and microelectromechanical system applications. J. Electrochem. Soc. 147(9), 3345–3349 (2000)

N. Nobari, M. Behboudnia, R. Maleki, Palladium-free electroless deposition of pure copper film on glass substrate using hydrazine as reducing agent. Appl. Surf. Sci. 385, 9–17 (2016)

D. Ashkenazi, I. Nusbaum, Y. Shacham-Diamand, D. Cvikel, Y. Kahanov, A. Inberg, A method of conserving ancient iron artefacts retrieved from shipwrecks using a combination of silane self-assembled monolayers and wax coating. Corros. Sci. 123, 88–102 (2017)

A. Ulman, Formation and structure of self-assembled monolayers. Chem. Rev. 96(4), 1533–1554 (1996)

F. Schreiber, Structure and growth of self-assembling monolayers. Prog. Surf. Sci. 65(5–8), 151–256 (2000)

A. Duhin, A. Inberg, N. Eliaz, E. Gileadi, Electroless plating of rhenium–nickel alloys. Electrochim. Acta 56, 9637–9643 (2011)

T. Wojtkielo Snyder, Black in black. MJSA J. (Special issue, May), 33–37 (2011)

M. Rein, A jewelry artists guide to liver of sulfur patinas and finishes. (Cool Tools, 2009), pp. 1–6

G. Galimberti, E.L. Doubrovski, M. Guagliano, B. Previtali, J.C. Verlinden, Investigating the links between the process parameters and their influence on the aesthetic evaluation of selective laser melted parts, in The 27th Annual International Solid Freeform Fabrication Symposium (2016), pp. 2367–2387

E. Glickman, A. Inberg, V. Bogush, G. Aviram, N. Croitoru, Y. Shacham-Diamand, On the mechanism of annealing effect in electrical resistivity of sub-100 nm Ag (1% W) films. Microelectron. Eng. 76, 182–189 (2004)

V. Sabayev, N. Croitoru, A. Inberg, Y. Shacham-Diamand, The evolution and analysis of electrical percolation threshold in nanometer scale thin films deposited by electroless plating. Mater. Chem. Phys. 127, 214–219 (2011)

S. Armyanov, T. Vangelova, R. Stoyanchev, Pretreatment of Al–Mg alloys for electrodeposition by immersion zinc and electroless nickel. Surf. Technol. 17(2), 89–100 (1982)

S. Court, C. Kerr, C. Ponce de León, J.R. Smith, B.D. Barker, F.C. Walsh, Monitoring of zincate pre-treatment of aluminium prior to electroless nickel plating. Trans. IMF 95(2), 97–105 (2017)

P. Zhu, Y. Masuda, K. Koumoto, Seedless micropatterning of copper by electroless deposition on self-assembled monolayers. J. Mater. Chem. 14(6), 976–981 (2004)

Acknowledgements

The research was supported by the Afeka Academic College of Engineering and the Tel Aviv University to whom the authors are grateful. The authors would like to thank Sharon Tuvia (1982) Ltd, Israel, for providing the facilities and printed samples for this research. The authors are thankful to Dr. H. Gitler, The Israel Museum Jerusalem, for his advice and encouragement. Thanks to S. Maman and A. Ulanov, Department of Mechanical Engineering, Afeka Academic College of Engineering, for their engineering assistance. Thanks to R. Burstein, Interplate Ltd, Israel, for the commercial silver coating, to Dr. D. Mogilevsky, Department of Materials Engineering, Ben-Gurion University of the Negev, for the XRD analysis. The authors would also like to thank Dr. M. Tkachev and Dr. Y. Fleger, Institute of Nanotechnology and Advanced Materials, Bar Ilan University, for their assistance with the FIB measurements, and to B. Doron for the English editing.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Dresler, N., Inberg, A., Ashkenazi, D. et al. Silver Electroless Finishing of Selective Laser Melting 3D-Printed AlSi10Mg Artifacts. Metallogr. Microstruct. Anal. 8, 678–692 (2019). https://doi.org/10.1007/s13632-019-00576-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13632-019-00576-7