Abstract

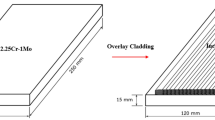

The present study investigates the effect of stress relief treatment at different temperatures (900, 1040, and 1200 °C) on the microstructure of Inconel 625 and A106 carbon steel weld joints. The results of the study show that, due to the generation of heat by welding, the bainite phase was formed in the heat-affected zone of A106 alloy. By applying stress relief treatment, even at the lowest temperature, the bainite phase was removed from the microstructure and the ferritic–pearlitic structure was formed. As the temperature of stress relief treatment increased, the grain size of the samples and the ratio of pearlite structure increased in the matrix. The morphology of the weld metal was converted from the columnar dendritic to an island state. Gradually, by increasing the temperature up to 1200 °C, austenitic grain boundary appeared in the microstructure. The SEM results confirmed the presence of complex molybdenum–niobium–rich carbides among secondary phase particles in the weld zone. In addition, an increase in the heat treatment temperature caused an increase in the concentration and dimensions of the carbides in the heat-affected zone, weld metal, and base metal of Inconel 625.

Similar content being viewed by others

References

K. Devendranath Ramkumar et al., Influence of filler metals in the control of deleterious phases during the multi-pass welding of Inconel 718 plates. Acta Metall. Sin. (Engl. Lett.) 28(2), 196–207 (2015). https://doi.org/10.1007/s40195-014-0185-5

H. Shah Hosseini, M. Shamanian, A. Kermanpur, Characterization of microstructures and mechanical properties of Inconel 617/310 stainless steel dissimilar welds. Mater. Charact. 62(4), 425–431 (2011). https://doi.org/10.1016/j.matchar.2011.02.003

N. Dudova, R. Kaibyshev, On the precipitation sequence in a 10% Cr steel under tempering. ISIJ Int. 51(5), 826–831 (2011). https://doi.org/10.2355/isijinternational.51.826

K. Devendranath Ramkumar, N. Arivazhagan, S. Narayanan, Effect of filler materials on the performance of gas tungsten arc welded AISI 304 and Monel 400. Mater. Des. 40, 70–79 (2012). https://doi.org/10.1016/j.matdes.2012.03.024

M.J. Donachie Jr., Relationship of Properties to Microstructure in Superalloys (American Society for Metals, Superalloys–Source Book, New York, 1984), pp. 102–111

J.K. Hong et al., Microstructures and mechanical properties of Inconel 718 welds by CO2 laser welding. J. Mater. Process. Technol. 201(1–3), 515–520 (2008). https://doi.org/10.1016/j.jmatprotec.2007.11.224

K.G. Kumar, K.D. Ramkumar, N. Arivazhagan, Characterization of metallurgical and mechanical properties on the multi-pass welding of Inconel 625 and AISI 316L. J. Mech. Sci. Technol. 29(3), 1039–1047 (2015). https://doi.org/10.1007/s12206-014-1112-4

S.G.K. Manikandan et al., Effect of weld cooling rate on Laves phase formation in Inconel 718 fusion zone. J. Mater. Process. Technol. 214(2), 358–364 (2014). https://doi.org/10.1016/j.jmatprotec.2013.09.006

H. Naffakh, M. Shamanian, F. Ashrafizadeh, Dissimilar welding of AISI 310 austenitic stainless steel to nickel-based alloy Inconel 657. J. Mater. Process. Technol. 209(7), 3628–3639 (2009). https://doi.org/10.1016/j.jmatprotec.2008.08.019

A. Olabi, M. Hashmi, Effects of the stress-relief conditions on a martensite stainless-steel welded component. J. Mater. Process. Technol. 77(1), 216–225 (1998). https://doi.org/10.1016/S0924-0136(97)00420-2

C. Pandey, M.M. Mahapatra, P. Kumar, N. Saini, Effect of weld consumable conditioning on the diffusible hydrogen and subsequent residual stress and flexural strength of multipass Welded P91 steels. Metall. Mater. Trans. B 49(5), 2881–2895 (2018). https://doi.org/10.1007/s11663-018-1314-8

C. Pandey, M.M. Mahapatra, Effect of heat treatment on microstructure and hot impact toughness of various zones of P91 welded pipes. J. Mater. Eng. Perform. 25(6), 2195–2210 (2016). https://doi.org/10.1007/s11665-016-2064-x

C. Pandey, M.M. Mahapatra, P. Kumar, N. Saini, Some studies on P91 steel and their weldments. J. Alloys Compd. 743, 332–364 (2018). https://doi.org/10.1016/j.jallcom.2018.01.120

C. Pandey, A. Giri, M.M. Mahapatra, P. Kumar, Characterization of microstructure of HAZs in as-welded and service condition of P91 pipe weldments. Met. Mater. Int. 23(1), 148–162 (2017). https://doi.org/10.1007/s12540-017-6394-5

C. Pandey, M.M. Mahapatra, P. Kumar, J.G. Thakre, N. Saini, Role of evolving microstructure on the mechanical behaviour of P92 steel welded joint in as-welded and post weld heat treated state. J. Mater. Process. Technol. 263, 241–255 (2019). https://doi.org/10.1016/j.jmatprotec.2018.08.032

C. Pandey, M.M. Mahapatra, P. Kumar, N. Saini, Comparative study of autogenous tungsten inert gas welding and tungsten arc welding with filler wire for dissimilar P91 and P92 steel weld joint. Mater. Sci. Eng. A 712, 720–737 (2018). https://doi.org/10.1016/j.msea.2017.12.039

C.C. Silva et al., New insight on the solidification path of an alloy 625 weld overlay. J. Mater. Res. Technol. 2(3), 228–237 (2013). https://doi.org/10.1016/j.jmrt.2013.02.008

J. Watson, J. Christian, Low-temperature properties of K-Monel, Inconel-X, René 41, Haynes 25, and Hastelloy B sheet alloys. J. Fluids Eng. 84(2), 265–277 (1962). https://doi.org/10.1115/1.3657301

A.S.M. Handbook, Vol. 1-Properties and Selection: Irons, Steels, and High-Performance Alloys. ASM International (1990). https://doi.org/10.31399/asm.hb.v01.9781627081610

S. Lee et al., Effect of carbide distribution on the fracture toughness in the transition temperature region of an SA 508 steel. Acta Mater. 50(19), 4755–4762 (2002). https://doi.org/10.1016/S1359-6454(02)00313-0

S. Seddighi, F. Ostovan, E. Shafiei, M. Toozandehjani, A study on the effect of stress relief heat treatment on the microstructure and mechanical properties of dissimilar GTAW weld joints of Inconel 625 and A106 carbon steel. Mater. Res. Express 6(8), 086582 (2019). https://doi.org/10.1088/2053-1591/ab1fcb

Porter, D.A., K.E. Easterling, M. Sherif, Phase Transformations in Metals and Alloys (Revised Reprint, 2009). https://doi.org/10.1201/9781439883570

A. Itman Filho et al., Influence of niobium and molybdenum on mechanical strength and wear resistance of microalloyed steels. Mater. Res. 20(4), 1029–1034 (2017). https://doi.org/10.1590/1980-5373-mr-2016-1101

T. Thorvaldsson, G. Dunlop, Grain boundary Cr-depleted zones in Ti and Nb stabilized austenitic stainless steels. J. Mater. Sci. 18(3), 793–803 (1983). https://doi.org/10.1007/BF00745578

H. Zhang et al., Effect of precipitated carbides on the fretting wear behavior of Inconel 600 alloy. Wear 315(1), 58–67 (2014). https://doi.org/10.1016/j.wear.2014.03.012

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Sedighi, S., Ostovan, F., Shafiei, E. et al. Microstructural Changes During Stress Relief Heat Treatment of Inconel 625–A106 Carbon Steel Joint. Metallogr. Microstruct. Anal. 8, 495–505 (2019). https://doi.org/10.1007/s13632-019-00562-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13632-019-00562-z