Abstract

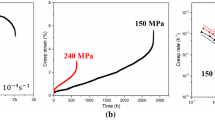

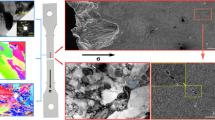

The mechanisms for the formation of Laves phase located at grain boundaries and in grain interiors in Sanicro 25 steel after creep-rupture test at 700 °C and 150/180 MPa for 9862/5665 h were studied, respectively. Scanning electron microscopy, transmission electron microscopy, energy-dispersive X-ray spectrometer, and multi-phase separation technology analysis reveals that Laves phase particles nucleated adjacently either to Si-enriched spots present in the bulky M23C6 carbides or to the grain boundary areas rich in Si, which made the bulky M23C6 carbides gradually divide into small pieces and eventually resulted in the formation of a refined mixture of M23C6 and Laves phase at grain boundaries. Laves phase particles formed independently in austenitic matrix and also dependently at interfaces between austenitic matrix and Z phase in grain interiors. The size and morphology of Laves phase formed at grain boundaries (in M23C6 carbides) and in grain interiors (austenitic matrix) are different. It is hoped that the presented findings will be helpful to understand the Laves phase formation and the grain boundary precipitate refinement correlated with good mechanical properties of this class of austenitic steels/alloys.

Similar content being viewed by others

References

Sanicro 25, Sandvik Materials Technology, Sweden. https://www.materials.sandvik/products/tube-pipe-fittings-and-flanges/high-performance-materials/high-temperature-stainless-steels/sanicro-25/faq-sanicro-25/ (2018)

R. Rautio, S. Bruce, Alloy for ultrasupercritical coal fired boilers. Adv. Mater. Process. 166, 35–37 (2008)

G. Chai, Damage mechanism of low cycle fatigue in an advanced heat resistant austenitic stainless steel at high temperature. Procedia Mater. Sci. 3, 1754–1759 (2014)

Y.M. Lee, S.I. Kwun, Y.H. Chung, Study on the slope change in the Larson–Miller plot of 23Cr-26Ni-W austenitic heat-resistant steel. Met. Mater. Int. 20(2), 233–241 (2014)

B. Rutkowski, A. Gil, W. Ratuszek, B. Woźnik, A. Czyrska-Filemonowicz, The microstructure of the Sanicro 25 steel after steam oxidation studied by advanced electron microscopy and spectroscopy methods. Inżynieria Materiałowa. 5(213), 223–227 (2016)

G. Chai, M. Boström, M. Olaison, U. Forsberg, Creep and LCF behaviors of newly developed advanced heat resistant austenitic stainless steel for A-USC. Procedia Eng. 55, 232–239 (2013)

M.I. Isik, A. Kostka, V.A. Yardley, K.G. Pradeep, M.J. Duarte, P.P. Choi, D. Raabe, G. Eggeler, The nucleation of Mo-rich Laves phase particles adjacent to M23C6 micrograin boundary carbides in 12% Cr tempered martensite ferritic steels. Acta Mater. 90, 94–104 (2015)

M.I. Isik, A. Kostka, G. Eggeler, On the nucleation of Laves phase particles during high-temperature exposure and creep of tempered martensite ferritic steels. Acta Mater. 81, 230–240 (2014)

Y.T. Xu, Y.H. Nie, M.J. Wang, W. Li, X.J. Jin, The effect of microstructure evolution on the mechanical properties of martensite ferritic steel during long-term aging. Acta Mater. 131, 110–122 (2017)

Z.F. Peng, S. Liu, C. Yang, F.Y. Chen, F.F. Peng, The effect of phase parameter variation on hardness of P91 components after service exposures at 530–550 °C. Acta Mater. 143, 141–155 (2018)

Z.F. Peng, L.S. Cai, F.F. Peng, Y.Y. Dang, F.Y. Chen, Effect of δ-ferrite on the composition and volume fraction of precipitates in P92 steel aged at 700 and 750 °C. Acta Metall. Sin. 48(11), 1315–1320 (2012)

T. Tokairin, K.V. Dahl, H.K. Danielsen, F.B. Grumsen, T. Sato, J. Hald, Investigation on long-term creep rupture properties and microstructure stability of Fe–Ni based alloy Ni–23Cr–7 W at 700 °C. Mater. Sci. Eng. A 565, 285–291 (2013)

J.P. Shingledecker, N.D. Evans, Creep-rupture performance of 0.07C–23Cr-45Ni-6W-Ti, Nb austenitic alloy (HR6W) tubes. Int. J. Pres. Ves. Pip. 87, 345–350 (2010)

I. Tarigan, K. Kurata, N. Takata, T. Matsuo, M. Takeyama, Novel concept of creep strengthening mechanism using grain boundary Fe2Nb Laves phase in austenitic heat resistant steel. Mater. Res. Sci. Symp. Proc. 1295, 317–322 (2011)

R.L. Plaut, C. Herrera, D.M. Escriba, P.R. Rios, A.F. Padilha, A short review on wrought austenitic stainless steels at high temperatures: processing, microstructure, properties and performance. Mater. Res. 10(4), 453–460 (2007)

J. Przemysław, S. Maria, Precipitation processes in HR6 W alloy after long-term ageing. Solid State Phenom. 246, 33–38 (2016)

N. Fonstein, Advanced High Strength Sheet Steels: Physical Metallurgy, Design, Processing, and Properties (Springer, Basel, 2015)

P.M. Kelly, The effect of particle shape on dispersion hardening. Scripta Metall. 6, 647–656 (1972)

Acknowledgements

The authors would like to acknowledge the Center for Electron Microscopy, especially Prof. Yaoyao Ren and Prof. Shizhou Pu, at Wuhan University for the TEM work.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Suo, J., Peng, Z., Yang, H. et al. Formation of Laves Phase in Sanicro 25 Austenitic Steel During Creep-Rupture Test at 700 °C. Metallogr. Microstruct. Anal. 8, 281–286 (2019). https://doi.org/10.1007/s13632-019-00529-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13632-019-00529-0