Abstract

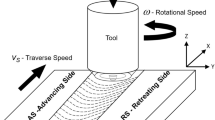

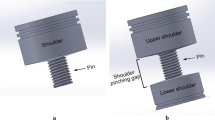

The 7000 series aluminum alloys provide the highest strength of all aluminum alloys and are widely used in the aerospace industries. They are practically unweldable by conventional fusion welding techniques. Friction stir welding is a widely accepted process to join this material. The paper intends to evaluate the electrochemical behavior of friction-stir-welded AA 7075-T651 alloy under varying welding conditions. An attempt has been made to evaluate the effect of tool rotation speed, welding speed, and shoulder diameter on its corrosion characteristics. The temperature histories during welding were continuously recorded with the help of thermocouples. The corrosion characteristics have been examined as per ASTM G-34 standards. The analysis is done by immersing the plates in EXCO solution and analyzing through optical imaging, SEM and TEM. The analysis revealed that the heat-affected zone was found to be most susceptible to corrosion. The corrosion resistance is found in the order—weld nugget > unwelded base metal > HAZ. The experiments revealed that the corrosion resistance of the welded plates is directly proportional to the heat input during the welding process. The plates welded with lower tool rotation speed, higher welding speed, and lower shoulder diameter exhibited higher corrosion resistance.

Similar content being viewed by others

References

S. Rajakumar, C. Muralidharan, V. Balasubramanian, Influence of friction stir welding process and tool parameters on strength properties of AA7075-T6 aluminium alloy joints. Mater. Des. 32(2), 535–549 (2011)

D.M. Rodrigues, A. Loureiro, C. Leitao, R.M. Leal, B.M. Chaparro, P. Vilaça, Influence of friction stir welding parameters on the microstructural and mechanical properties of AA 6016-T4 thin welds. Mater. Des. 30(6), 1913–1921 (2009)

A.H. Feng, D.L. Chen, Z.Y. Ma, Microstructure and cyclic deformation behavior of a friction-stir-welded 7075 Al alloy. Metall. Mater. Trans. A 41(4), 957–971 (2010)

B.T. Gibson, D.H. Lammlein, T.J. Prater, W.R. Longhurst, C.D. Cox, M.C. Ballun, K.J. Dharmaraj, G.E. Cook, A.M. Strauss, Friction stir welding: Process, automation, and control. J. Manuf. Process. 16(1), 56–73 (2014)

R.K. Gupta, P. Ramkumar, B.R. Ghosh, Investigation of internal cracks in aluminium alloy AA7075 forging. Eng. Fail. Anal. 13(1), 1–8 (2006)

H.K. Rafi, G.D.J. Ram, G. Phanikumar, K.P. Rao, Microstructure and tensile properties of friction welded aluminum alloy AA7075-T6. Mater. Des. 31(5), 2375–2380 (2010)

M.W. Mahoney, C.G. Rhodes, J.G. Flintoff, W.H. Bingel, R.A. Spurling, Properties of friction-stir-welded 7075 T651 aluminum. Metall. Mater. Trans. A 29(7), 1955–1964 (1998)

M. Selvaraj, M. Vela, S.R. Koteswara Rao, Mechanism of weld formation during friction stir welding of aluminum alloy. Mater. Manuf. Process. 28(5), 595–600 (2013)

K. Deepandurai, R. Parameshwaran, Multiresponse optimization of FSW parameters for cast AA7075/SiCp composite. Mater. Manuf. Processes 31(10), 1333–1341 (2016)

K.V. Jata, S.L. Semiatin, Continuous dynamic recrystallization during friction stir welding of high strength aluminum alloys. Scr. Mater. 43(8), 743–749 (2000)

C.G. Rhodes, M.W. Mahoney, W.H. Bingel, R.A. Spurling, C.C. Bampton, Effects of friction stir welding on microstructure of 7075 aluminum. Scr. Mater. 36(1), 69–75 (1997)

P.L. Threadgill, A.J. Leonard, H.R. Shercliff, P.J. Withers, Friction stir welding of aluminium alloys. Int. Mater. Rev. 54(2), 49–93 (2009)

A.O. Mosleh, F.H. Mahmoud, T.S. Mahmoud, T.A. Khalifa, Microstructure and static immersion corrosion behavior of AA7020-O Al plates joined by friction stir welding. Proc. Inst. Mech. Eng. L J. Mater. Des. Appl. 230(6), 1030–1040 (2015)

A. Behnagh, G. Besharati, M. Akbari, Mechanical properties, corrosion resistance, and microstructural changes during friction stir processing of 5083 aluminum rolled plates. Mater. Manuf. Process. 27(6), 636–640 (2012)

D.A. Dragatogiannis, E.P. Koumoulos, I. Kartsonakis, D.I. Pantelis, P.N. Karakizis, C.A. Charitidis, Dissimilar friction stir welding between 5083 and 6082 Al alloys reinforced with TiC nanoparticles. Mater. Manuf. Process. 31(16), 2101–2114 (2016)

J.B. Lumsden, M.W. Mahoney, G. Pollock, C.G. Rhodes, Intergranular corrosion following friction stir welding of aluminum alloy 7075-T651. Corrosion 55(12), 1127–1135 (1999)

F.M. Khoshnaw, R.H. Gardi, Effect of aging time and temperature on exfoliation corrosion of aluminum alloys 2024-T3 and 7075-T6. Mater. Corros. 58(5), 345–347 (2007)

T. Venugopal, K. Srinivasa Rao, K. Prasad Rao, Studies on friction stir welded AA 7075 aluminium alloy. Trans. Indian Inst. Met. 57(6), 659–663 (2004)

F. Andreatta, H. Terryn, J.H.W. de Wit, Corrosion behaviour of different tempers of AA7075 aluminium alloy. Electrochim. Acta 49(17–18), 2851–2862 (2004)

C.S. Paglia, M.C. Carroll, B.C. Pitts, T. Reynolds, R.G. Buchheit, Strength, corrosion, and environmentally assisted cracking of a 7075-T6 friction stir weld. Mater. Sci. Forum 396–402, 1677–1684 (2002)

J. Kang, R.-D. Fu, G.-H. Luan, C.-L. Dong, M. He, In-situ investigation on the pitting corrosion behavior of friction stir welded joint of AA2024-T3 aluminium alloy. Corros. Sci. 52(2), 620–626 (2010)

Rajesh, S., Badheka, V.J.: Effect of friction stir lap weld and post weld heat treatment on corrosion behavior of dissimilar aluminum alloys, in Proceedings of the Institution of Mechanical Engineers, Part L: Journal of Materials: Design and Applications. 1464420717692150 (2017)

G. Elatharasan, V.S. Senthil Kumar, Corrosion analysis of friction stir-welded AA 7075 Aluminium Alloy. J. Mech. Eng. 60(1), 29–34 (2014)

I.J. Polmear, Light Alloys—Metallurgy of the light metals, 3rd edn. (Arnold Publishers, London, 1995)

C.S. Paglia, R.G. Buchheit, A look in the corrosion of aluminum alloy friction stir welds. Scr. Mater. 58(5), 383–387 (2008)

W. Tian, S. Li, B. Wang, J. Liu, M. Yu, Pitting corrosion of naturally aged AA 7075 aluminum alloys with bimodal grain size. Corros. Sci. 113, 1–16 (2016)

A. Chemin, D. Marques, L. Bisanha, A.D.J. Motheo, W.W. Bose Filho, C.O.F. Ruchert, Influence of Al7Cu2Fe intermetallic particles on the localized corrosion of high strength aluminum alloys. Mater. Des. 53, 118–123 (2014)

S. Rajesh, V. Badheka, Influence of heat input/multiple passes and post weld heat treatment on strength/electrochemical characteristics of friction stir weld joint. Mater. Manuf. Process. 33(2), 156–164 (2018)

K.D. Ralston, N. Birbilis, C.H.J. Davies, Revealing the relationship between grain size and corrosion rate of metals. Scr. Mater. 63(12), 1201–1204 (2010)

K. Srinivasa Rao, K. Prasad Rao, Pitting corrosion of heat-treatable aluminium alloys and welds: a review. Trans. Indian Inst. Met. 57(6), 593–610 (2004)

Acknowledgements

The writers would sincerely like to thank Indian Space Research Organisation (ISRO), India, for the monetary assistance given through a R&D Project No. E33011/60/2010-V. Authors would like to thank Pandit Deendayal Petroleum University (PDPU), Gandhinagar, India, for their help in providing a platform for conducting the experimental work required for the investigation.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Shah, P.H., Badheka, V. Effect of Various Welding Parameters on Corrosion Behavior of Friction-Stir-Welded AA 7075-T651 Alloys. Metallogr. Microstruct. Anal. 7, 308–320 (2018). https://doi.org/10.1007/s13632-018-0440-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13632-018-0440-7