Abstract

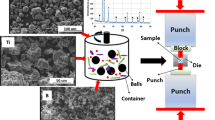

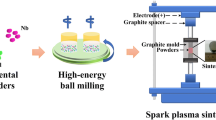

In this study, nano-TiO2 (1.0–2.0 wt.%)-dispersed Zr-based alloys with nominal compositions: 45Zr–30Fe–20Ni–5Mo (alloy 1), 44Zr–30Fe–20Ni–5Mo–1TiO2 (alloy 2) and 44Zr–30Fe–20Ni–4Mo–2TiO2 (alloy 3) are synthesized by mechanical alloying in a dual-drive planetary ball mill followed by powder consolidation with conventional sintering at 1400 °C/spark plasma sintering at 900–1000 °C. For microstructural and phase analysis of mechanically alloyed powders and consolidated products, XRD, SEM/EDS and TEM studies were carried out. Density measurement and mechanical property (compressive strength, hardness and wear) characterization were also carried out. X-ray diffraction and TEM analysis reveal formation of different intermetallics of 10–30 nm size along with TiO2 (10–20 nm) throughout the matrix of the consolidated samples. Alloys consolidated by spark plasma sintering displayed high levels of compressive strength (825–1240 MPa) and hardness (10.38–16.85 GPa) which was 1.5–2 times higher than that was obtained in conventional sintering. Addition of TiO2 helps in enhancement of mechanical properties, and effect was more prominent with 2.0 wt.% TiO2.

Similar content being viewed by others

References

M. Steinbrueck, Oxidation of zirconium alloys in oxygen at high temperatures up to 1600 C. Oxid. Met. 70(5–6), 317–329 (2008)

V.O. Kharchenko, D.O. Kharchenko, Ab-initio calculations for structural properties of Zr-Nb alloys. arXiv preprint arXiv:1206.7035 (2012)

O.-H. Kwon, K.-B. Eom, J.-I. Kim, J.-M. Suh, K.-L. Jeon, Mechanical and irradiation properties of zirconium alloys irradiated in hanaro. Nucl. Eng. Technol. 43(1), 19–24 (2011)

S.S. Yardley, K.L. Moore, N. Ni, J.F. Wei, S. Lyon, M. Preuss, S. Lozano-Perez, C.R. Grovenor, An investigation of the oxidation behaviour of zirconium alloys using isotopic tracers and high resolution SIMS. J. Nucl. Mater. 443(1), 436–443 (2013)

C. Suryanarayana, E. Ivanov, V. Boldyrev, The science and technology of mechanical alloying. Mater. Sci. Eng. A 304, 151–158 (2001)

K.M. Fox, Mechanical alloying and thermal treatment for production of zirconium-iron hydrogen isotope getters. J. Ceram. Process. Res. 10(6), 705–709 (2009)

A. Tonejc, Crystallographic features of mechanically milled and alloyed nanosized crystalline and amorphous materials. Acta Chim. Slov. 49(1), 1–28 (2002)

J. Taek-Kyun, J. Dong-Woo, L. Seung-Yub, C. Myung-Sik, H. Soong-Keun, L. Hyo-Soo, Mechanical alloying of platinum with 5% ZrO 2 nanoparticles for glass making tools. Trans. Nonfer. Met. Soc. China 24, s99–s105 (2014)

T. Chen, P. Lee, Formation of amorphous Cu–Zr alloy powder by mechanical alloying. J. Mar. Sci. Technol. Taiwan 1(1), 59–64 (1993)

H. Fecht, G. Han, Z. Fu, W. Johnson, Metastable phase formation in the Zr–Al binary system induced by mechanical alloying. J. Appl. Phys. 67(4), 1744–1748 (1990)

M. Ristić, S. Milošević, Frenkel’s theory of sintering. Sci. Sinter. 38(1), 7–11 (2006)

O. Guillon, J. Gonzalez-Julian, B. Dargatz, T. Kessel, G. Schierning, J. Räthel, M. Herrmann, Field-assisted sintering technology/spark plasma sintering: mechanisms, materials, and technology developments. Adv. Eng. Mater. 16(7), 830–849 (2014)

H. Hahn, J. Logas, R.S. Averback, Sintering characteristics of nanocrystalline TiO 2. J. Mater. Res. 5(03), 609–614 (1990)

K. Rajeswari, U. Hareesh, R. Subasri, D. Chakravarty, R. Johnson, Comparative evaluation of spark plasma (SPS), microwave (MWS), two stage sintering (TSS) and conventional sintering (CRH) on the Densification and microstructural evolution of fully stabilised zirconia ceramics. Sci. Sinter. 42(3), 259–267 (2010)

X. Li, Y. Ye, Y. Tang, S. Qu, Effect of pulsed magnetic field on spark plasma sintering of iron-based powders. Mater. Trans. 51(7), 1308–1312 (2010)

J. Schmidt, T. Weissgaerber, T. Schubert, B. Kieback, Sintering II: spark plasma sintering of intermetallics and metal matrix composites, European Congress and exhibition on powder metallurgy. In: European PM Conference Proceedings, 2005, The European Powder Metallurgy Association, p 93

V. Mote, Y. Purushotham, B. Dole, Williamson-Hall analysis in estimation of lattice strain in nanometer-sized ZnO particles. J. Theor. Appl. Phys. 6(1), 1–8 (2012)

Z. Xie, R. Liu, Q. Fang, Y. Zhou, X. Wang, C. Liu, Spark plasma sintering and mechanical properties of zirconium micro-alloyed tungsten. J. Nucl. Mater. 444(1), 175–180 (2014)

C. Hochmuth, D. Schliephake, R. Völkl, M. Heilmaier, U. Glatzel, Influence of zirconium content on microstructure and creep properties of Mo–9Si–8B alloys. Intermetallics 48, 3–9 (2014)

M. Nuthalapati, S. Karak, D. Chakravarty, A. Basu, Development of nano-Y2O3 dispersed Zr alloys by mechanical alloying and spark plasma sintering. Mater. Sci. Eng. A 650, 145–153 (2016)

M. Nuthalapati, S. Karak, J.D. Majumdar, A. Basu, phase evolution and mechanical properties of nano-TiO2 dispersed Zr-based alloys by mechanical alloying and conventional sintering. Metall. Mater. Trans. A 45(9), 3748–3754 (2014)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Nuthalapati, M., Karak, S.K., Chakravarty, D. et al. Comparative Study on Microscopic, Physical and Mechanical Properties of Conventional and Spark Plasma Sintered Nano-TiO2-Dispersed Zirconium-Based Alloys. Metallogr. Microstruct. Anal. 6, 527–540 (2017). https://doi.org/10.1007/s13632-017-0393-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13632-017-0393-2