Abstract

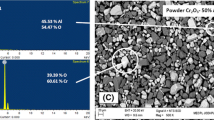

This research work was focused on the performance of HVOF-sprayed 83WC–17CO and 86WC–10CO–4Cr coatings on boiler steel alloys ASME SA213 T22 and ASME SA213 T91 in a coal-fired boiler environment. Both coated and bare steel alloys were subjected to cyclic exposures, in the superheater zone of a coal-fired boiler for 10 cycles at 900 °C to compare the effect of the coatings in actual boiler environment. During the study, each cycle consisted of 100-h heating followed by 1-h cooling at ambient conditions and thereafter thermogravimetric method was used to establish the kinetics of corrosion. Corrosion products were examined by x-ray diffraction, scanning electron microscopy/energy-dispersive spectroscopy techniques. The hot corrosion resistance of both the coatings 83WC–17CO and 86WC–10CO–4Cr coating was found better on ASME SA213 T22, whereas 86WC–10CO–4Cr coating showed the higher corrosion resistance on ASME SA213 T22 as compared to 83WC–17CO coating.

Similar content being viewed by others

References

H. Edris, D.G. McCartney, A.J. Sturgeon, Microstructural characterization of high velocity oxy-fuel sprayed coatings of Inconel 625. J. Mater. Sci. 32, 863–868 (1997)

P. Hancock, Vanadic and chloride attack of superalloys. Mater. Sci. Technol. 3, 536–544 (1987)

N. Priyantha, P. Jayaveera, A. Sanjurjo, K. Lau, F. Lu, K. Krist, Corrosion resistant metalic coatings for application in high aggressive environments. Surf. Coat. Technol 163–164, 31–36 (2003)

A. Vaidhya, T. Streibl, L. Li, S. Sampath, O. Kovarik, R. Greenlaw, An integrated study of thermal spray process–structure–property correlations: a case study for plasma sprayed molybdenum coatings. Mater. Sci. Eng. A 403, 191–204 (2005)

D.H. Singh, D. Puri, S. Prakash, Some studies on hot corrosion performance of plasma sprayed coatings on a Fe-based superalloy. Surf. Coat. Technol. 192, 27–38 (2005)

J. Kawakita, S. Kuroda, T. Fukushima, T. Kodama, Improvement of corrosion resistance of high velocity oxy-fuel sprayed stainless steel coatings by addition of Molybdenum. J. Therm. Spray Technol. 14, 224–230 (2005)

T.S. Sidhu, S. Prakash, R.D. Agrawal, Hot corrosion studies of HVOF sprayed Cr3C2–NiCr and Ni–20Cr coatings on nickel-based superalloy at 900 °C. Surf. Coat. Technol. 201, 792–800 (2006)

H.S. Sidhu, B.S. Sidhu, S. Prakash, Mechanical and microstructural properties of HVOF sprayed WC–Co and Cr3C2–NiCr coatings on the boiler tube steels using LPG as the fuel gas. J. Mater. Process. Technol. 171, 77–82 (2006)

T.S. Sidhu, S. Prakash, R.D. Agrawal, Characterisation of NiCr wire coating on Ni- and Fe-based superalloys by the HVOF process. Surf. Coat. Technol. 200, 5542–5549 (2006)

B.S. Sidhu, S. Prakash, Performance of NiCrAlY, Ni–Cr, Stellite-6 and Ni3Al coatings in Na2So4–60%V2O5 environment at 900 °C under cyclic conditions. Surf. Coat. Technol. 201, 1643–1654 (2006)

T.S. Sidhu, S. Prakash, R.D. Agrawal, Performance of high velocity oxyfuel-sprayed coatings on an Fe-based superalloy in Na2So4–60%V2O5 environment at 900 °C Part II: Hot corrosion behaviour of the coatings. J. Mater. Eng. Perform. 15, 130–138 (2006)

T.S. Sidhu, S. Prakash, R.D. Agrawal, Study of molten salt corrosion of high velocity oxy-fuel sprayed cermet and nickel-based coatings at 900 °C. Metall. Mater. Trans. A 38A, 77–85 (2007)

G. Goyal, H. Singh, S. Prakash, Effect of superficially applied ZrO2 inhibitor on the high temperature corrosion performance of some Fe-, Co- and Ni-base superalloys. Appl. Surf. Sci. 254, 6653–6661 (2008)

R.A. Mahesh, R. Jayaganthan, S. Prakash, Evaluation of hot corrosion behaviour of HVOF sprayed NiCrAl coating on superalloys at 900 °C. Mater. Chem. Phys. 111, 524–533 (2008)

G. Kaushal, H. Singh, S. Prakash, Surface engineering by detonation-gun spray coating of 347H boiler steel to enhance its high temperature corrosion resistance. Mater. High Temp. 28, 1–11 (2011)

R. Goyal, V. Chawla, B.S. Sidhu, State of art: thermal spraying and performance of hard coatings: a review. Int. J. Res. Mech. Eng. Technol 1, 22–26 (2011)

M. Kaur, Surface engineering analysis of detonation-gun sprayed Cr3C2–NiCr coating under high-temperature oxidation and oxidation–erosion environments. Surf. Coat. Technol. 206, 530–541 (2011)

S.S. Chatha, H.S. Sidhu, B.S. Sidhu, The effects of post-treatment on the hot corrosion behavior of the HVOF-sprayed Cr3C2–NiCr coating. Surf. Coat. Technol. 206, 4212–4224 (2012)

S.B. Mishra, K. Chandra, S. Prakash, Erosion–corrosion performance of NiCrAlY coating produced by plasma spray process in a coal-fired thermal power plant. Surf. Coat. Technol. 216, 23–34 (2013)

V.P.S. Sidhu, K. Goyal, R. Goyal, Corrosion behaviour of HVOF sprayed coatings on ASME SA213 T22 boiler steel in an actual boiler environment. Adv. Eng. Forum 20, 1–9 (2017)

S. Singh, K. Goyal, R. Goyal, Performance of Ni3Al And TIO2 coatings on T22 boiler tube steel in simulated boiler environment in laboratory. J. Mech. Eng. 46(1), 54–61 (2017)

S. Singh, K. Goyal, R. Goyal, Performance of Cr3C2-25 (Ni–20Cr) and Ni–20Cr coatings on T22 boiler tube steel in simulated boiler environment. J. Thin Films Coat. Sci. Technol. Appl. 3(2), 19–26 (2016)

M. Kumar, H. Singh, N. Singh, R.S. Joshi, Erosion–corrosion behavior of cold-spray nanostructured Ni–20Cr coatings in actual boiler environment. Wear 332, 1035–1043 (2015)

G. Singh, K. Goyal, R. Bhatia, Hot corrosion studies of plasma-sprayed chromium oxide coatings on boiler tube steel at 850 °C in simulated boiler environment. Iran. J. Sci. Technol. Trans. Mech. Eng. (2017). doi:10.1007/s40997-017-0090-4

X. Zhang, X. Zhang, X. Jie, X. Jie, L. Zhang, L. Zhang et al., Improving the high-temperature oxidation resistance of H13 steel by laser cladding with a WC/Co-Cr alloy coating. Anti-Corrosion Methods Mater. 63(3), 171–176 (2016)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Sidhu, V.P.S., Goyal, K. & Goyal, R. Comparative Evaluation of Hot Corrosion Resistance of 83WC–17CO and 86WC–10CO–4Cr Coatings on Some Boiler Steels in Actual Boiler in Thermal Power Plant. Metallogr. Microstruct. Anal. 6, 512–518 (2017). https://doi.org/10.1007/s13632-017-0392-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13632-017-0392-3