Abstract

Agriculture is the key for achieving the United Nations sustainable development goals: food security and climate action. To achieve these targets “climate-smart” agricultural practices need to be developed. Life cycle assessment and product carbon footprints are well established and internationally recognized tools to assist the process of improving environmental performance. However, there is room for methodological improvement of agricultural life cycle assessments and product carbon footprints. For agronomists, it is widely known that crop rotations and crop residues do fulfill important agronomic functions, but they are not adequately represented in current life cycle assessment and product carbon footprint modeling practice. New methods tested in this study allow the inclusion of crop rotation effects and crop residues as co-products, whilst keeping at the same time the product focus. Product carbon footprints are calculated with and without consideration of these effects; results are compared. If crop rotations are considered, wheat bread, cow milk, and rapeseed biodiesel have lower product carbon footprints (− 11, − 22, and − 16%, respectively). The product carbon footprint of straw bioethanol significantly increases (+ 80%) when considering straw as an agricultural co-product instead of as waste. Ignoring crop rotation effects underestimates the annual greenhouse gas savings of EU-28 rapeseed biodiesel by 1.67 million t CO2e and 20%, respectively. Here, we demonstrate for the first time that crop rotations and straw harvest should be considered for the product carbon footprints of bread, milk, and first- and second-generation biofuels. Since crop rotations and straw harvest are performed worldwide, the findings are relevant to all regions in the world. Comparing crop rotations and identifying climate-smart agricultural practices without losing the production orientation are key challenges for environmental assessments of agriculture in order to achieve the challenging combination of the food security and climate action sustainable development goals.

Similar content being viewed by others

1 Introduction

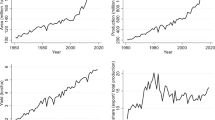

Agriculture is the key to achieving the United Nations (UN) sustainable development goals (SDGs): food security and climate Action. Population growth, climate change’s impacts on agricultural yields, and reduced availability of arable land per capita (Fig. 1) will lead to serious challenges in the coming decades. Besides being affected by climate change, agriculture itself has the potential to combat climate change (FAO 2010, 2013, 2015a; Lipper et al. 2014). There is a need to build highly resource-efficient agricultural systems, providing higher yields with less inputs, e.g., fertilizers (Spiertz 2010); to develop and assess regionalized farming tactics to increase food production with no cost to the environment (Liu et al. 2016); and to perform sustainable intensification (Wezel et al. 2015). Life cycle assessment (LCA) and product carbon footprints (PCFs) are appropriate tools for accurately estimating environmental burdens of farming activities (Schenck and Huizenga 2014; van der Werf et al. 2013).

Amount of arable land per capita (1961–2012) is a function of global arable land (1961–2012) and global total population. Arable land per capita has approximately halved from 0.415 ha/person in 1961 to 0.197 ha/person in 2012. The estimated increase of total global population (until 2100) will lead to a further decrease of arable land per capita. Thus, a further increase of agricultural productivity is needed to meet the future demand for food (FAO 2015b; United Nations 2015)

PCFs estimate greenhouse gas emissions of products and have already gained legal relevance and market importance, such as carbon footprint labeling of consumer products. Since PCFs use LCA methodology, they have the same methodological strengths and weaknesses as LCA. Concerning agriculture, standard approaches of these methodologies fail to consider differences among agricultural management options (Bessou et al. 2011), e.g., effects of crop rotations (Dury et al. 2012) and removing straw residues from fields (Fig. 2)—two essential aspects of agricultural practice (Brankatschk and Finkbeiner 2015). Fundamental challenges of integrating crop rotations and of co-product allocation in agricultural LCA are discussed in LCA community at least since the 1990s and since the 2000s, respectively. The magnitude of this gap has not yet been quantified.

Here, we apply two new Life Cycle Inventory methods for the inclusion of these essential agricultural aspects: first is the cereal unit allocation approach for allocating environmental burdens among agricultural co-products and products. The basis is the biophysical cereal unit, which is based on the animal nutritional value. The cereal unit allocation is applicable to animal and plant products, traditionally used in German agricultural statistics and, in 2014, proposed as an agriculture-specific denominator for co-product allocation (Brankatschk and Finkbeiner 2014). Second is the crop rotation approach, which combines system expansion and allocation within the Life Cycle Inventory in order to integrate effects among crop rotation elements. It is the first approach that allows considering crop rotation effects and, at the same time, maintaining the product focus of LCA (Brankatschk and Finkbeiner 2015). Both of the methods are applied to show quantitative implications of excluding crop rotation effects and straw residues as co-products on the PCFs of wheat bread, cow milk, rapeseed biodiesel, and straw bioethanol.

2 Methods

For centuries, farmers have performed crop rotations to stabilize and improve yields (Wrightson 1921). In contrast, current product LCA and PCF modeling practices assess individual agricultural crops within a 1-year system boundary (option 1). This limits the ability to consider effects between crops grown in temporal succession on the same field. Approaches for modeling nutrient shifts between crops exist (option 2) but are limited to a few macronutrients and are not widely used (Brankatschk and Finkbeiner 2015). We apply an approach for including crop rotation effects into LCA/PCF (option 3) and compare its results to option 1.

Since the 1990s, LCA practitioners have recommended including crop rotations and their effects on soil into LCA (Audsley et al. 1997; Cowell and Clift 1995). These effects are not limited from one to the succeeding year. The following crop rotation effects are rather relevant on a longer time frame: “facilitated timing of farming activities, improved phytosanitary conditions and reduced amounts of agro-chemicals needed, reduction of the probability of harvest failures and improved conditions for soil organisms, improved soil texture, soil structure, root penetration and water availability, improved soil fertility and increased yields.” (Brankatschk and Finkbeiner 2015). To fill this gap, Brankatschk and Finkbeiner (2015) extended the system boundary to the entire crop rotation and used an agriculture-specific allocation approach to allocate all inputs of the crop rotation among all outputs of the crop rotation. This system boundary extension and allocation of inputs is performed during the data collection step of each LCA, the Life Cycle Inventory (LCI) (Brankatschk and Finkbeiner 2015). The following steps are used within this approach:

-

1.

“The crop-rotation system is identified … [and] the system boundary of the LCI (not that of the entire LCA study) is defined, including all elements around this crop-rotation system. The definitions of the functional unit and reference flow according to ISO 14040 (e.g. production of 1 t of wheat grain) thus remain unaffected ….

-

2.

The agronomic inputs (seed, diesel fuel, energy, agrochemicals, fertilizer, etc.) of the entire crop rotation cycle including all crops grown in the crop rotation are quantified.

-

3.

All outputs (including products, by-products, waste, leachate, emissions) of this crop rotation leaving the agricultural field are considered and quantified (i.e. tonnages of each individual product, such as wheat grain and the other products and co-products produced within the same crop rotation).

-

4.

All agricultural outputs for each crop in the rotation are converted into Cereal Units ….

-

5.

Allocation factors are calculated for each individual agricultural output of the entire crop rotation using the amounts given in Cereal Units ….

-

6.

Using the allocation factors …, the sum of each agricultural input (seed, diesel fuel, energy, agrochemicals, fertilizer, etc.) is allocated among all individual agricultural outputs.” (Brankatschk and Finkbeiner 2015)

Since the 2000s, LCA practitioners have called for an agriculture-specific allocation approach, especially to overcome the problem of using different allocation approaches within the same agricultural system; doing so can over- or underestimate real burdens and is thus a source of uncertainty in agricultural LCAs (Curran 2007; S. Kim and Dale 2002; Lundie et al. 2007). To meet this demand, Brankatschk and Finkbeiner proposed the cereal unit allocation approach, which applies the established cereal unit from agricultural sciences to the methodology of life cycle assessment (Brankatschk and Finkbeiner 2014; Mönking et al. 2010). The cereal unit is a common denominator for all (animal and plant) agricultural products and co-products; it is calculated based on the nutritional value of the products to animals and continuously updated and has been used in German agricultural statistics since the 1940s (Brankatschk and Finkbeiner 2014). For the determination of a cereal unit (CU) conversion factor, the metabolizable energy content of different agricultural products is used and compared as a benchmark with the performance of barley. Therefore, 1 t of barley grains is equal to 1.00 t CU. As wheat has better animal nutritional parameters, 1 t of wheat grains is equal to 1.04 t CU. A detailed explanation of the calculation steps and a list of conversion factors for more than 200 agricultural products were published by Brankatschk and Finkbeiner (2014).

Straw residues are agricultural co-products and influence soil structure, soil texture, and populations of soil organisms. They protect soil against erosive impacts of water and wind; they improve hydrological properties for infiltration and water runoff and enhance porosity, water retention, gaseous fluxes, heat fluxes, and availability of macro- and micronutrients; they provide habitat and nourishment source for soil organisms (Brankatschk and Finkbeiner 2015). Thus, straw residues contribute to important soil quality parameters and consequently affect soil fertility and yields. As a consequence, harvested straw should be considered as a co-product in environmental assessments. Straw, remaining on the field, contributes to soil functions and does not cross system boundaries; therefore, remaining straw is not considered as a co-product. A differentiation is required between harvested straw and straw, remaining on the field.

The following procedure was performed to assess the influence of considering crop rotations and straw residues in results of PCF. First, existing LCA or PCF studies were identified for wheat bread, cow milk, rapeseed biodiesel, and straw bioethanol. Since nitrogen fertilization is one of the largest contributors to agricultural greenhouse gas (GHG) emissions (Berthoud et al. 2012), it was used as the key variable. In the context of this study, the amount of nitrogen fertilizer was varied, whereas types of nitrogen fertilizers and emission factors remained unaffected. Other parameters (e.g., other fertilizers, processing, and transport) were fixed to exclude their influence on PCF results. Second, numerical contributions of nitrogen fertilization to the product’s PCFs were identified and verified whether the PCFs did consider crop rotation effects. Third, the nitrogen fertilization, needed for the specific crop, was calculated using the previously explained crop rotation approach and the proportional deviation from the amount of nitrogen fertilization needed for the 1-year cropping system was calculated. Fourth, the GHG emissions related to the nitrogen fertilization of the 1-year system within the original PCFs were replaced by the respective GHG emissions for the system including crop rotations. Fifth, the PCF considering the crop rotation effects is obtained. This procedure aims at making differences between PCFs, using current methodology versus new methods visible. To some extent, this can be considered as sensitivity analysis for current modeling practice versus new methods.

2.1 Reference studies

Several PCF studies exist for each of the selected products, but identification of the most accurate one for each product lay beyond the scope of this work. Selected PCFs should rather be understood as estimates and benchmarks for comparing current modeling practice to the proposed modeling approaches that consider crop rotations and crop residues.

Wheat bread has a PCF of approximately 460 g CO2e/kg (Braschkat et al. 2004). Approximately 57% of its GHG emissions relate to the agricultural stage (Braschkat et al. 2004) and 75% of them to nitrogen fertilization (Berthoud et al. 2012). Therefore, 43% of its GHG emissions (approximately 200 g CO2e/kg) are directly related to nitrogen fertilization.

Cow milk has a PCF of approximately 1240 g CO2e/L, of which 510 g CO2e/L is associated with feed production (Müller-Lindenlauf et al. 2014). Assuming that 75% of the agricultural production relates to nitrogen fertilization of feed crops (Berthoud et al. 2012), approximately 380 g CO2e/L is directly related to nitrogen fertilization.

Rapeseed biodiesel has a PCF of 46 g CO2e/megajoule (MJ) (RED 2009). Approximately 62% of its GHG emissions relate to the agricultural stage and 82% of them to nitrogen fertilization (11.0 g CO2e/MJ) and nitrous oxide emissions (12.5 g CO2e/MJ). The typical GHG reduction potential of rapeseed biodiesel is 45% compared to fossil diesel, based on the legally binding value of 83.8 g CO2e/MJ (RED 2009).

Straw bioethanol has a PCF of 11 g CO2e/MJ (RED 2009). For its agricultural production phase, the EU Renewable Energy Directive (RED) states: “agricultural crop residues, including straw…, shall be considered to have zero life-cycle greenhouse gas emissions up to the process of collection of those materials” (RED 2009). Thus, 0.00 g CO2e/MJ is used for the agricultural stage. The entire burden of wheat production is allocated to wheat grain, the main product. To calculate a PCF that includes agricultural emissions, the agricultural stage was modeled using the BioGrace calculation tool (see below); typical GHG emissions from the RED were added for processing (5 g CO2e/MJ) and transport (2 g CO2e/MJ) (RED 2009).

2.2 Integrating crop rotation effects and crop residues in PCF results

GHG calculations and intermediate calculations for both biofuels are performed using the BioGrace tool, version 4d. This Microsoft® Excel-based calculation tool entails a harmonized GHG calculation methodology along the entire biofuel supply chain, including calculation of direct and indirect nitrous oxide emissions following the IPCC Tier 1 approach. BioGrace is recognized by the European Commission for calculating GHG emissions of biofuel production in compliance with the EU RED (BioGrace 2015).

LCIs were generated for wheat (W), barley (B), rapeseed (R), and pea (P). Crops were chosen due to their relevance for European agriculture; wheat and barley represent two thirds of the EU-28 cereal production, rapeseed is the main feedstock for biodiesel production, and pea was chosen as nitrogen-fixing plant. The crops are modeled both as individually grown (i.e., 1-year system boundary; Table 3) and as elements of a crop rotation (R-W-P-W-B; Table 2). Mean yields and nutrient compositions of crops and crop residues were obtained from agricultural statistics and agricultural planning tables for Germany and other parts of Europe. In practice, crop rotations are often more complex than the chosen example. A mathematical representation of different crop rotation types helps considering complex rotations. Brankatschk and Finkbeiner (2015) clarify calculation procedure for complex rotations.

Integration of crop rotation effects is tested for the PCFs of bread, milk, and biodiesel. For bread production, wheat grain is considered as an agricultural raw material. For milk production, barley grain, wheat grain, wheat straw, and rapeseed meal are considered inputs. For biodiesel production, rapeseeds are considered as a raw material. Consideration of crop rotation effects is performed using the previously mentioned method that takes place during Life Cycle Inventory only: firstly, extending the system boundary to the entire crop rotation, and secondly, allocating all inputs of the crop rotation among the outputs of the crop rotation using an agriculture-specific allocation approach—i.e., the cereal unit (Brankatschk and Finkbeiner 2015). The resulting amount of nitrogen fertilizer per ton of each agricultural product entails the crop rotation effects. For the examples of bread, milk, biodiesel, and bioethanol, we assumed 1% of the straw to be harvested and 99% of the straw remaining on the field (Table 1). This amount of nitrogen fertilizer was used in the PCF calculation, resulting in PCFs of bread, milk, and biodiesel that consider crop rotation effects.

Attribution of environmental burdens to straw residues was tested for the PCF of straw bioethanol. For straw bioethanol production, wheat straw is considered an agricultural raw material. Whereas 1% straw harvest was assumed for the crop rotation part of the study, here, we assumed 100% of the straw being harvested and considered as a co-product. Using the cereal unit allocation approach (Brankatschk and Finkbeiner 2014), we calculated the amount of nitrogen fertilizer per ton of wheat straw (Table 1). This amount corresponds to the nitrogen demand used in the PCF calculation, resulting in a PCF that includes straw residues with environmental burdens. Results are compared to PCFs based on current modeling practice, which ignores crop rotation effects and crop residues.

3 Results and discussion

Remarkably different PCFs were found for wheat bread, cow milk, and rapeseed biodiesel, even though only nitrogen input was used as a variable. If crop rotations are considered, bread, milk, and rapeseed biodiesel have lower PCFs (− 11, − 22, and − 16%, respectively) compared to current modeling practice (1-year systems) (Fig. 3). If straw is considered as a co-product, straw bioethanol has a significantly higher PCF (+ 80%) than it does under the current modeling practice (Fig. 3).

Comparison of product carbon footprints (PCFs) for wheat bread, cow milk, rapeseed biodiesel, and straw bioethanol using current modeling approaches: 1-year systems vs. crop rotation and straw as waste vs. straw as a co-product. Considering crop rotations leads to lower PCFs (bread, − 11%; milk, − 22%; biodiesel, − 16%) and considering waste as a co-product to higher PCFs (straw ethanol, + 80%)

With an exception of nitrogen inputs, other parameters were fixed, in order to exclude their influence on PCF results. The differences presented mainly refer to the methods tested and to the aspects of crop rotation effects and crop residue allocation, which become measurable via the tested methods. Each method brings limitations. During application of the methods, some advantages and disadvantages were observed, which are shortly discussed below. An extensive method discussion would go beyond the scope of this paper. The advantage of the cereal unit allocation is the common denominator for assessing animal and vegetable products, which allows performing farm LCAs without changing the allocation approach. It helps avoiding unintended double counting or non-accounting of environmental interventions. Due to the physical relationship, based on animal feeding trials, the cereal unit allocation has a high ranking in the ISO hierarchy for allocation approaches. Whereas more than 200 cereal unit conversion factors do exist, they are only valid for German conditions. For use in other regions in the world, new conversion factors need to be calculated, which limits the applicability of the cereal unit allocation approach. The major advantage of the crop rotation approach is incorporation of crop rotation effects into LCA results whilst, at the same time, allowing product-based assessments. Temporal and spatial aspects of agricultural systems are taken into account. Hereby, product LCAs become able to represent whether the agricultural raw materials originate from improved crop rotations. Disadvantages of this method are additional data requirements for the entire crop rotation and additional workload for the LCA practitioner. Furthermore, the environmental interventions are attributed among all products according to the performance principle—when using the cereal unit as allocation, the animal nutritional value determines the allocation of environmental interventions. This also implies the attribution of interventions to all crop rotation elements, whereas these interventions may not occur for each of the elements in the crop rotation. For certain situations, e.g., for N fertilization of legumes, the combination of different ways of attributing burdens to crops may also serve as an interesting option; this aspect is explained in Goglio et al. (2017).

The following subsections are focusing at considering crop rotations (3.1), considering crop residues (3.2), and sustainable agricultural practices (3.3).

3.1 Impacts of considering crop rotations

Wheat grain assessed in 1-year system boundaries has a nitrogen input of 22.03 kg N/t (Table 3). When considering crop rotation effects, the nitrogen input is equal to 16.70 kg N/t wheat grain (Tables 1 and 2). Thus, the PCF of bread decreases from 460 g CO2e/kg by 50 g CO2e/kg to 410 g CO2e/kg, a decrease of 11% (Table 1, Fig. 3). Barley grain assessed in 1-year system boundaries has a nitrogen input of 19.94 kg N/t. When considering crop rotation effects, the nitrogen input is equal to 16.06 kg N/t barley grain, a decrease of 19% (Tables 1 and 2). Wheat straw assessed in 1-year system boundaries (and 1% straw harvest scenario) has a nitrogen input of 9.11 kg N/t (Tables 1 and 3). When considering crop rotation effects (also 1% straw harvest scenario), the nitrogen input is equal to 6.91 kg N/t wheat straw, a decrease of 25% (Table 1). Rapeseeds assessed in 1-year system boundaries have a nitrogen input of 45.15 kg N/t (Table 3). When considering crop rotation effects, the nitrogen input is equal to 20.88 kg N/t rapeseeds (Table 2), a decrease of 54% (Table 1). Based on these results, a reduction of 30% of nitrogen inputs for the feedstuffs has been applied. Thus, the PCF of milk decreases from 1240 g CO2e/L by 270 g CO2e/L to 970 g CO2e/L, a decrease of 22% (Table 1, Fig. 3).

The 1-year system boundaries assessed for rapeseeds of 45.15 kg N/t nitrogen input (Table 3) show a good match with data from BioGrace of 44.14 kg N/t, which strictly follows the RED, and therefore represent European data (BioGrace 2015). Hence, BioGrace models individual crop growth within a 1-year system boundary; neither nitrogen transfer to subsequent crops nor crop rotations are considered. If crop rotation effects are considered, the nitrogen input is equal to 20.88 kg N/t rapeseeds (Table 2), a decrease of 54% (Table 1). The PCF of rapeseed biodiesel decreases from 46 g CO2e/MJ due to the reduced amount of nitrogen fertilizer by 5.8 g CO2e/MJ and due to the reduced direct and indirect nitrous oxide emissions by 1.7 to 38.5 g CO2e/MJ, a decrease of 16% (Table 1, Fig. 3). In terms of GHG savings, the potential of 45% GHG reduction increases by 9 to 54% GHG reduction. Accordingly, the annual GHG savings of EU-28 rapeseed biodiesel consumption (approximately 6.0 million t rapeseed biodiesel) increases from 8.44 million t CO2e by 1.67 million t CO2e, or 20%, to 10.11 million t CO2e.

PCFs of bread, milk, and biodiesel are lower when including crop rotation effects, as some nitrogen remains as crop residues on the field and serves as fertilizer for subsequent crops. In contrast, within 1-year systems, total nitrogen demand is modeled as a fertilizer input, ignoring transfers of nitrogen between crops. Even though approaches for modeling nitrogen transfer from one crop to subsequent crops do exist, they apparently were not used in any of the PCF studies referenced (Berthoud et al. 2012; BioGrace 2015; Braschkat et al. 2004; Müller-Lindenlauf et al. 2014; RED 2009).

Interactions between crop rotation elements, such as nutrient flows, effects of soil organisms, and soil fertility, were identified as influencing PCF results. Moreover, crop rotations can improve soil nutrient resources and efficiency of nutrient use and even reduce the need for manure and chemical fertilizers (Łukowiak et al. 2016). These effects occur over longer time period than 1 year. Within the crop rotation planning, farmers do explicitly consider effects of individual crops. As team players contribute to the success of a team, individual crops contribute to the performance of the entire crop rotation. Current modeling practice does not distinguish between crops grown in rotations, in monoculture or in 1-year systems without nutrient transfer between crops. Thus, there is limited ability to compare environmental impacts of crops grown in different crop rotation systems; however, this ability is necessary to identify crop rotations with lower environmental impacts, to assist farmers in identifying “climate-smart” farming practices and to move towards both sustainable development goals: food security and climate action.

3.2 Impacts of considering crop residues

Following the European legal definition for PCF calculation of biofuels, straw residues have a nitrogen input of 0.00 kg N/t wheat straw (RED 2009); the GHG emissions of straw bioethanol are equal to 11 g CO2e/MJ. We recalculate a PCF that considers straw residues as the co-product of wheat production. Here, we assume 100% of the harvest-ready straw being harvested (put by the combine harvester on a windrow, collected by a straw baler) and applied the cereal unit allocation that expresses the animal nutritional value (Brankatschk and Finkbeiner 2014). Using the BioGrace tool, we calculate emissions of 1943.8 kg CO2e/ha wheat and yields of 7640 kg wheat grain/ha, 6110 kg wheat straw/ha, and a nitrogen input of 168.84 kg N/ha. One kilogram wheat straw is used to produce 0.29 L straw bioethanol (Seungdo Kim and Dale 2004) or 6.173 MJ straw bioethanol/kg wheat straw; thus, 37,717 MJ straw bioethanol/ha is produced. Applying the cereal unit allocation to wheat grain (75.1%) and wheat straw (24.9%) (Brankatschk and Finkbeiner 2014), we calculate an environmental burden of 12.83 g CO2e/MJ straw bioethanol for the agricultural stage. After including the emissions of processing (5 g CO2e/MJ straw bioethanol) and transport (2 g CO2e/MJ straw bioethanol) (RED 2009), the total PCF is equal to 19.83 g CO2e/MJ straw bioethanol. Hence, the GHG emissions of straw bioethanol rise by 8.8 g CO2e/MJ, from 11 to 19.83 g CO2e/MJ, an increase of 80% (Table 1, Fig. 3). In terms of GHG savings, the potential of 87% GHG reduction compared to fossil fuel decreases by 11 to 76% GHG reduction (see Fig. 4).

Comparison of product carbon footprints (PCF) of straw bioethanol: harvested straw considered as waste (calculation based on the EU Renewable Energy Directive; RED rules) vs. harvested straw considered as co-product (calculation based on ISO rules). The PCF of fossil diesel (obtained from the RED) serves as benchmark. The greenhouse gas (GHG) saving potential of straw bioethanol deviates 11 percentage points (87 vs. 76%)

The RED requires allocating zero environmental burden from the agricultural phase to straw (RED 2009). According to ISO 14044, “it is necessary to identify the ratio between co-products and waste since the inputs and outputs shall be allocated to the co-products part only (ISO 14044 2006). Hence, in an LCA and PCF context, the RED treats harvested straw as waste. This is not in line with the international LCA and PCF standards ISO 14040, 14044, and 14067 (Brankatschk and Finkbeiner 2015). The RED definition means that the amount of straw necessary to produce a given amount of bioethanol is irrelevant to the latter’s PCF. Consequently, there is no incentive to use resources efficiently. In addition, important functions of straw seem to be disregarded, such as those for animal bedding, animal nutrition, and improvement of soil fertility (Brankatschk and Finkbeiner 2015). The overall relevance of crop residues to protection against erosion, nutrient recycling, carbon sequestration, humus balance, activity and diversity of soil organisms, holding capacity for nutrients and water, soil fertility, and thus future yields seems to be ignored (Brankatschk and Finkbeiner 2015; Lal 2005, 2009).

Considering straw as waste in PCF calculations of biofuels could be politically motivated to promote non-food bioenergy feedstocks, avoid debates about food versus fuel, or provide an advantage to non-food-based biofuels when estimating reductions in GHG emissions. Another explanation could be a lack of understanding of the need to distinguish between harvested straw and remaining straw. Two systematic advantages are granted to straw-based biofuels. Firstly, they carry zero environmental burden from the agricultural stage, and secondly, their burden is allocated to their food-grade co-products. Food crop-based biofuels are hereby systematically disadvantaged. However, this approach seems unbalanced, because unlimited straw harvest affects soil fertility and, thus, future yields, including food yields on the same field.

Certain amounts of straw might be available for harvesting without affecting soil fertility (Gabrielle and Gagnaire 2008). These amounts depend on local conditions, may vary sharply, and should be defined in collaboration with soil scientists. A parallel line can be drawn to von Carlowitz’s (1713) book about reforestation, Silvicultura Oeconomica. It underlines the need for the balance between timber harvest and growth, formulating in this context the term sustainability. We contend that this principle should be transferred to straw harvest. Sustainable amounts of straw harvest should be defined that do not negatively affect long-term soil fertility and that ensure future yields. Furthermore, straw harvest practices may influence long-term soil carbon changes; increasing carbon in agricultural soils serves as carbon sink, whereas decreasing carbon content in soils leads to a release of carbon to the atmosphere. This aspect is not considered within this study.

3.3 Life Cycle Inventory methods for assessing sustainable agricultural practices

Within this work, two new Life Cycle Inventory methods are applied and tested, i.e., the cereal unit allocation approach (Brankatschk and Finkbeiner 2014) and the crop rotation approach (Brankatschk and Finkbeiner 2015). To ensure their compatibility with attributional LCAs, they should be conformed to existing international LCA standards, e.g., ISO 14040 and ISO 14044.

ISO 14044 provides a hierarchy for dealing with multi-output processes (ISO 14044 2006): first, avoiding allocation via subdivision of processes in subprocesses or expanding the product system—which is hardly feasible for agricultural production processes that characteristically do have multiple outputs and would cause additional uncertainties (Brankatschk and Finkbeiner 2014; Lundie et al. 2007); secondly, using physical allocation; and if not feasible, thirdly, applying economic allocation. The cereal unit allocation is based on animal nutritional value and therefore uses physical connections as basis for allocation (Brankatschk and Finkbeiner 2014). The cereal unit allocation has been developed to overcome the co-product allocation challenge of agricultural production processes and serves as an agriculture-specific biophysical allocation approach. It is therefore in line with the ISO standards for LCA. Following the ISO hierarchy, higher priority should be given to biophysical allocation approaches compared to economic allocation. Aiming to include effects among crop rotation elements into attributional LCA, the crop rotation approach has been developed. It introduces a supplementary step into the existing LCI and does not affect other stages of LCA. It purposefully combines the well-known product system expansion (to the level of the entire crop rotation) with an agriculture-specific allocation approach. It can be applied with any allocation approach that serves as a common denominator for the agricultural products. In this study, the cereal unit has been used as the common denominator. Accordingly, the crop rotation approach is compatible to the ISO. Further details are provided in Brankatschk and Finkbeiner (2015). Therefore, both of the methods are in line with ISO 14044 and compatible to attributional life cycle assessments for agricultural systems.

Another important standard is the AGRIBALYSE method (Koch and Salou 2016). The AGRIBALYSE program started in 2009 and can be considered as a methodological standard in France. Herein, the French Environment and Energy Management Agency (ADEME) collaborates with a number of French and international organizations aiming to provide a consistent LCI database of French agricultural products. AGRIBALYSE databases are already publicly available and continuously updated. Background data are obtained from the ecoinvent database (version 3.1). The system boundary ends at farm gate, and therefore, primary processing of agricultural raw materials is excluded—e.g., grain milling and oilseed crushing. AGRIBALYSE defines an LCA assessment period of 1 year (harvest to harvest for plant production; January to December for livestock or permanent crops). When using the crop rotation approach, the same system boundary can apply at the LCA level, because the crop rotation approach only refers to the LCI. Hence, the tested crop rotation approach could assist future AGRIBALYSE versions in integrating crop rotation effects. With regard to the consideration of crop residues, i.e., straw, AGRIBALYSE suggests allocating the environmental burden among wheat grains and wheat straw using the economic allocation, acknowledging wheat straw is being harvested on 16% of the area and a wheat straw yield of 577 kg dry matter per ha. This is in line with the argumentation, provided in the previous section on impacts of crop residues and the need to allocate environmental burdens to harvested straw. But, the limited availability of straw prices prevents AGRIBALYSE from performing this allocation step in its current version (Koch and Salou 2016). The proposed cereal unit allocation as a biophysical allocation approach can overcome this problem of data availability and has even higher priority in the ISO allocation hierarchy. AGRIBALYSE already uses biophysical allocation approaches for livestock production. Using a biophysical allocation approach as well for plant products would be consistent within AGRIBALYSE. In that context, the cereal unit allocation can serve as a universal approach for both animal and plant production.

Comparison of methods tested within this paper and AGRIBALYSE method shows accordance with regard to the ISO standards. The concept of using biophysical relationships, which is the core of cereal unit allocation, is already partly integrated within AGRIBALYSE for livestock production and could be easily transferred to plant production, which even solves limitations in data availability and allows consistent co-product and crop residue allocation.

For centuries, crop rotations have been fundamental tools for securing and increasing yields (Wrightson 1921). To meet the challenges of future food provision and combating climate change, it is certain that crop rotations will gain additional relevance. There is urgent need to help farmers identify crop rotations that both reduce environmental impacts and respect the production function of agriculture. Reliable and accurate tools are needed to fulfill this task. Apart from considering nutrient carryover via crop residues (Nemecek et al. 2011), current modeling practice is not able to compare environmental burdens of different crop rotation options at the product level (Alföldi et al. 1999; Brankatschk and Finkbeiner 2015; Nemecek et al. 2011). Usually, crops are individually modeled in a 1-year system boundary, even though the need for improvement has been recognized since the 1990s (Brankatschk and Finkbeiner 2015; Cowell and Clift 1995; Flisch et al. 2009). To make LCA and PCF methodology capable of supporting agricultural planning and drawing well-founded decisions towards sustainable agricultural practices (Pelletier 2015), it is necessary to represent differences caused by different crop rotations (Brankatschk and Finkbeiner 2015).

The methods applied confirm a production-oriented performance principle in LCA and PCF. They use the agriculture-specific cereal unit, which is based on animal nutritional value (Brankatschk and Finkbeiner 2014). It serves as a common denominator for all agricultural products and co-products and a variety of production systems. The animal nutritional value reflects future demand for food and feed better than the economic value or lower heating value used in the current LCA and PCF modeling (Brankatschk and Finkbeiner 2014). By allocating environmental burdens to the same target, comparisons of different agricultural production systems become more reliable. In particular, comparing crop rotations and identifying climate-smart agricultural practices without losing the production orientation of agricultural systems are key challenges for environmental assessments in the next few decades—formulated in the sustainable development goals: food security and climate action. Similarly, potential impacts on soil fertility, and thus on future yields, of the crop residues left after harvesting should be given a closer look. This is in line with the overall trend in LCA development towards life cycle sustainability assessment (LCSA) that includes the environmental, economic, and social dimensions of sustainability (Finkbeiner et al. 2014; Finkbeiner et al. 2010; Guinée et al. 2011).

4 Conclusion

This study demonstrates the influence of modeling practices and methodological weaknesses on environmental assessments of bioeconomy products such as food, feed, fiber, and biofuels. Crops were modeled either as 1-year systems or as crop rotations, and straw was treated either as waste or as a co-product. To date, these options have received little attention by PCF users or LCA practitioners. This study quantifies the impacts of different modeling options on PCF results. Hereby, sustainability scientists, political decision-makers, and the general public gain insights into challenges of modeling agricultural production systems. In order to quantify the relevance of methodological choices and to derive information on the sensitivity of crop rotations and crop residues to LCA results, further case studies should be carried out and published.

The influence of potentially political decisions on PCF calculations, such as allocating zero environmental burden to straw used to produce bioethanol in Europe, is made visible. Consequently, environmental impacts of many agricultural products may be over- or underestimated. It is likely that public perception, political decisions, and even emission reporting of entire countries are affected. This study suggests that the ignoring of crop rotation effects leads to underestimation of annual GHG savings of rapeseed biodiesel in the EU-28 by 1.67 million t CO2e. For comparison, total biofuel GHG savings in Germany is equal to 5 million t CO2e. Because crop rotations are performed around the globe, the findings are relevant for environmental assessments of agriculture in every region of the world.

The tested modeling approach for crop rotations reveals as a real alternative to current modeling options and hereby supports the development and identification of sustainable agricultural practices. Without inclusion of crop rotation effects, environmental advantages of improvements in agricultural practices enabled by crop rotations would remain undetected. To keep pace with future needs and trends in agriculture and agricultural policies, crop rotations must be considered in LCA and PCFs.

We strongly recommend further testing and improvement of these methods, since they will be essential for evaluating the impacts of various agricultural management options. Reliable and meaningful assessment tools will be needed to help agriculture achieve the challenging combination of the SDGs food security and climate action.

References

Albrecht R, Guddat C (2004) Welchen Wert haben Körnerleguminosen in der Fruchtfolge (What is the value of grain legumes in crop rotations). In

Alföldi T, Schmid O, Gaillard G, Dubois D (1999) Life cycle assessment of integrated and organic crop production. Agrarforschung 6(9):337–340

Audsley E, Alber S, Gemeinschaften E (1997) Harmonisation of environmental life cycle assessment for agriculture. European Comm., DG VI Agriculture

Berthoud A, Buet AL, Genter T, Marquis S (2012) Comparison of the environmental impact of three forms of nitrogen fertilizer. Retrieved from Paris: http://fertilizerseurope.com/fileadmin/user_upload/publications/agriculture_publications/Enviro_Impact-V9.pdf

Bessou C, Ferchaud F, Gabrielle B, Mary B (2011) Biofuels, greenhouse gases and climate change. A review. Agron Sustain Dev 31(1):1. https://doi.org/10.1051/agro/2009039

BioGrace (2015) BioGrace Excel tool—version 4d—harmonised calculations of biofuel greenhouse gas emissions in Europe. Retrieved 14 June 2015, from Align biofuel GHG emission calculations in Europe (BioGrace). http://www.biograce.net; http://www.biograce.net/content/ghgcalculationtools/recognisedtool/; http://www.biograce.net/img/files/2015-05-12-161933BioGrace-I_GHG_calculation_tool_-_version_4d.zip

BMEL, & BLE (2015) Besondere Ernte- und Qualitätsermittlung BEE 2014 (Special harvesting and quality determination BEE 2014). Retrieved from Berlin: http://www.bmelv-statistik.de/de/fachstatistiken/besondere-ernteermittlung/http://berichte.bmelv-statistik.de/EQB-1002000-2014.pdf

Brankatschk G, Finkbeiner M (2014) Application of the cereal unit in a new allocation procedure for agricultural life cycle assessments. J Clean Prod 73:72–79. https://doi.org/10.1016/j.jclepro.2014.02.005

Brankatschk G, Finkbeiner M (2015) Modeling crop rotation in agricultural LCAs—challenges and potential solutions. Agric Syst 138:66–76. https://doi.org/10.1016/j.agsy.2015.05.008

Braschkat J, Patyk A, Quirin M, Reinhardt G (2004) Life cycle assessment of bread production—a comparison of eight different scenarios. Paper presented at the life cycle assessment in the agri-food sector. Proceedings from the 4th international conference, Bygholm (DK), 6–8 October 2003, Bygholm, Denmark

Cowell S, Clift R (1995) Life cycle assessment for food production systems. In: Fertiliser Society

Curran MA (2007) Studying the effect on system preference by varying coproduct allocation in creating life-cycle inventory. Environ Sci Technol 41(20):7145–7151. https://doi.org/10.1021/es070033f

DIRECTIVE 2009/28/EC on the promotion of the use of energy from renewable sources (RED) (2009)

Dury J, Schaller N, Garcia F, Reynaud A, Bergez JE (2012) Models to support cropping plan and crop rotation decisions. A review. Agron Sustain Dev 32(2):567–580. https://doi.org/10.1007/s13593-011-0037-x

Eurostat (2015) Crops products—annual data. Retrieved 14 June 2015, from European Commission; http://appsso.eurostat.ec.europa.eu/

Eurostat, & European Union (2007) The use of plant protection products in the European Union: data 1992-2003. EUR-OP, Luxembourg

FAO (2010) Climate-smart” agriculture—policies, practices and financing for food security, adaptation and mitigation. Retrieved from Rome: http://www.fao.org/docrep/013/i1881e/i1881e00.htmhttp://www.fao.org/docrep/013/i1881e/i1881e00.pdf

FAO (2013) Climate-smart agriculture—sourcebook. Retrieved from Rome: http://www.fao.org/climate-smart-agriculture/72611/en/http://www.fao.org/docrep/018/i3325e/i3325e.pdf

FAO (2015a) Breakthrough climate agreement recognizes food security as a priority [press release]. Retrieved from http://www.fao.org/news/story/en/item/358257/icode/

FAO (2015b) FAO statistics division—arable land world. FAOSTAT Retrieved 5 September 2015, from FAO Food and Agriculture Organization of the United Nations; http://faostat3.fao.org/download/R/RL/E

finanzen.net (2015) finanzen.net: Börse und Finanzen. Retrieved from http://www.finanzen.net

Finkbeiner M, Schau EM, Lehmann A, Traverso M (2010) Towards life cycle sustainability assessment. Sustainability 2(10):3309. https://doi.org/10.3390/su2103309

Finkbeiner M, Ackermann R, Bach V, Berger M, Brankatschk G, Chang Y-J et al (2014) Challenges in life cycle assessment: an overview of current gaps and research needs. In: Klöpffer W (ed) Background and future prospects in life cycle assessment. Springer, Dordrecht, pp 207–258

Flisch R, Sinaj S, Charles R, Richner W (2009) GRUDAF 2009. Principles for fertilisation in arable and fodder production. Agrarforschung 16(2):1–100

Gabrielle B, Gagnaire N (2008) Life-cycle assessment of straw use in bio-ethanol production: a case study based on biophysical modelling. Biomass Bioenergy 32(5):431–441. https://doi.org/10.1016/j.biombioe.2007.10.017

Goglio P, Brankatschk G, Knudsen MT, Williams AG, Nemecek T (2017) Addressing crop interactions within cropping systems in LCA. Int J Life Cycle Assess. https://doi.org/10.1007/s11367-017-1393-9

Guinée JB, Heijungs R, Huppes G, Zamagni A, Masoni P, Buonamici R et al (2011) Life cycle assessment: past, present, and future. Environ Sci Technol 45(1):90–96. https://doi.org/10.1021/es101316v

http://www.agrarheute.com (2015) Nachrichten für die Landwirtschaft | agrarheute.com. Retrieved from http://www.agrarheute.com/markt-uebersicht. Retrieved from http://www.agrarheute.com/raps. Retrieved from http://www.agrarheute.com/gerste-551190. Retrieved from http://www.agrarheute.com/erzeugerpreise-stroh

ISO 14044 (2006) ISO 14044. Environmental management—life cycle assessment—requirements and guidelines. In. Geneva: International Organization for Standardization (ISO)

Kaltschmitt M, Hartmann H, Hrsg HH (2009) Energie aus Biomasse: Grundlagen, Techniken und Verfahren [Energy from biomass: fundamentals, techniques and procedures], 2nd edn. Springer, Dordrecht

Kim S, Dale BE (2002) Allocation procedure in ethanol production system from corn grain—I. System expansion. Int J Life Cycle Assess 7(4):237–243. https://doi.org/10.1065/lca2002.05.081

Kim S, Dale BE (2004) Global potential bioethanol production from wasted crops and crop residues. Biomass Bioenergy 26(4):361–375. https://doi.org/10.1016/j.biombioe.2003.08.002

Koch P, Salou T (2016) AGRIBALYSE®: Rapport Méthodologique—version 1.3. Retrieved from Angers, France: http://www.ademe.fr/en/expertise/alternative-approaches-to-production/agribalyse-program. http://www.ademe.fr/sites/default/files/assets/documents/agribalyse_v1_3_methodology.pdf. http://www.ademe.fr/sites/default/files/assets/documents/agribalyse_fs_v1_3.xlsx. http://www.ademe.fr/sites/default/files/assets/documents/agribalyse_v1_3_report_of_changes_2016.pdf

KTBL (2015) Verfahrensrechner Pflanze (calculator for crop production processes). Available from KTBL KTBL Verfahrensrechner Pflanze Retrieved 15. Februar 2015, from KTBL Kuratorium für Technik und Bauwesen in der Landwirtschaft e. V. (Association for Technology and Structures in Agriculture); http://daten.ktbl.de/vrpflanze/prodverfahren

Lal R (2005) World crop residues production and implications of its use as a biofuel. Environ Int 31(4):575–584. https://doi.org/10.1016/j.envint.2004.09.005

Lal R (2009) Soil quality impacts of residue removal for bioethanol production. Soil Tillage Res 102(2):233–241. https://doi.org/10.1016/j.still.2008.07.003

LfL (2013) Basisdaten fuer die Ermittlung des Duengebedarfs, fuer die Umsetzung der Duengeverordung,zur Berechnung des KULAP-Naaehrstoff-Saldos, zur Berechnung der Nährstoffbilanz nach Hoftor-Ansatz (Basic data: for the determination of nutrient demand, for the implementation of fertilizer ordinance, to calculate the KULAP-nutrient-balance, to calculate the nutrient balance using farm-gate approach). In (pp. 25): LfL Bayerische Landesanstalt für Lanwirtschaft (The Bavarian State Research Center for Agriculture)

Lipper L, Thornton P, Campbell BM, Baedeker T, Braimoh A, Bwalya M et al (2014) Climate-smart agriculture for food security. Nat Clim Chang 4(12):1068–1072. https://doi.org/10.1038/nclimate2437

Liu C, Cutforth H, Chai Q, Gan Y (2016) Farming tactics to reduce the carbon footprint of crop cultivation in semiarid areas. A review. Agron Sustain Dev 36(4):69. https://doi.org/10.1007/s13593-016-0404-8

Łukowiak R, Grzebisz W, Sassenrath GF (2016) New insights into phosphorus management in agriculture—a crop rotation approach. Sci Total Environ 542(Part B):1062–1077. https://doi.org/10.1016/j.scitotenv.2015.09.009

Lundie S, Ciroth A, Huppes G (2007) Inventory methods in LCA: towards consistency and improvement—final report. Retrieved from http://www.estis.net/includes/file.asp?site=lcinit&file=1DBE10DB-888A-4891-9C52-102966464F8D

Mönking SS, Klapp C, Abel H, Theuvsen L (2010) Überarbeitung des Getreide- und Vieheinheitenschlüssels—Endbericht zum BMELV-Forschungsprojekt 06HS030 [Revision of cereal unit and livestock unit—Final report on research project 06HS030 BMELV] (06HS030). Retrieved from Göttingen: http://download.ble.de/06HS030.pdf. http://service.ble.de/fpd_ble/index2.php?detail_id=706&site_key=154&stichw_suche=DUMMY&zeilenzahl_zaehler=1353&NextRow=630. http://service.ble.de/fpd_ble/index2.php?site_key=154&stichw_suche=DUMMY&NextRow=630. http://www.ble.de/cln_090/nn_467852/DE/04__Forschungsfoerderung/Forschungsfoerderung__node.html?__nnn=true

Müller-Lindenlauf M, Cornelius C, Gärtner S, Reinhardt G, Rettenmaier N, Schmidt T (2014) Umweltbilanz von Milch- und Milcherzeugnissen—Status quo und Ableitung von Optimierungspotenzialen. Retrieved from Heidelberg: http://www.milchindustrie.de/aktuelles/pressemitteilungen/umweltbilanz-von-milch-und-milcherzeugnissen-erstellt/. http://www.milchindustrie.de/uploads/tx_news/IFEU-VDM-Milchbericht-Umweltbilanz-2014_01.pdf

Nemecek T, Huguenin-Elie O, Dubois D, Gaillard G, Schaller B, Chervet A (2011) Life cycle assessment of Swiss farming systems: II. Extensive and intensive production. Agric Syst 104(3):233–245. https://doi.org/10.1016/j.agsy.2010.07.007

Pelletier N (2015) Life cycle thinking, measurement and management for food system sustainability. Environ Sci Technol 49(13):7515–7519. https://doi.org/10.1021/acs.est.5b00441

Schenck R, Huizenga D (2014, 8-10 October 2014). Proceedings of the 9th international conference on life cycle assessment in the Agri-Food Sector (LCA Food 2014). Paper presented at the 9th International Conference on Life Cycle Assessment in the Agri-Food Sector (LCA Food 2014), San Francisco

Spiertz JHJ (2010) Nitrogen, sustainable agriculture and food security. A review. Agron Sustain Dev 30(1):43–55. https://doi.org/10.1051/agro:2008064

TLL, Guddat C, Degner J, Zorn W, Götz R, Paul R, Baumgärtel T (2010) Leitlinie zur effizienten und umweltverträglichen Erzeugung von Ackerbohnen und Körnererbsen (Guideline for efficient and environment-friendly production of field beans and peas). Jena: TLL Thüringer Landesanstalt für Landwirtschaft (The Thuringian State Research Centre for Agriculture). Retrieved from http://www.tll.de/ainfo/pdf/ll_abke.pdf

United Nations (2015) World population prospects: the 2015 revision. Retrieved from http://esa.un.org/unpd/wpp/

van der Werf HMG, Corson M, Wilfart A (2013) LCA food 2012—towards sustainable food systems. Int J Life Cycle Assess:1–4. https://doi.org/10.1007/s11367-013-0571-7

von Carlowitz HC (1713) Sylvicultura oeconomica. Johann Friedrich Braun, Leipzig

von Richthofen, J-S, Pahl H, Nemecek T, Odermatt S, Charles R, Casta P, …, Lucassen J (2006) Economic interest of grain legumes in European crop rotations. Retrieved from

Wezel A, Soboksa G, McClelland S, Delespesse F, Boissau A (2015) The blurred boundaries of ecological, sustainable, and agroecological intensification: a review. Agron Sustain Dev, 35(4). https://doi.org/10.1007/s13593-015-0333-y

Wrightson J (1921) Agriculture theoretical and practical. Lockwood, London

Author information

Authors and Affiliations

Corresponding author

About this article

Cite this article

Brankatschk, G., Finkbeiner, M. Crop rotations and crop residues are relevant parameters for agricultural carbon footprints. Agron. Sustain. Dev. 37, 58 (2017). https://doi.org/10.1007/s13593-017-0464-4

Accepted:

Published:

DOI: https://doi.org/10.1007/s13593-017-0464-4