Abstract

Hydrochar (HC), a carbonaceous material that can be used as solid fuel, is produced from wet biomass through hydrothermal carbonization (HTC). In this investigation, activated hydrochar is derived from municipal sewage sludge and key lime peel biomass. The effect of heating rate on the prepared activated hydrochar and kinetic parameters is investigated at different heating rates of 10, 15, and 20 °C/min using thermogravimetric analysis (TGA). The objective of this study is to determine the kinetic parameters associated with technological factors in two variants of activated hydrochar, produced from two different combinations of municipal sewage sludge and key lime peel, specifically in ratios of 1:1 and 2:1. Using model-free kinetics techniques, the kinetics of sample-1 (i.e., 1:1 blend ratio) and sample-2 (i.e., 2:1 blend ratio) degradation kinetics are analyzed. Three different kinetic models, namely Kissinger-Akahira-Sunose (KAS), Flynn-Wall-Ozawa (FWO), and Starink, are applied to assess the activation energies of hydrochar sample-1 and hydrochar sample-2. Activation energies for sample-1, using the Ozawa, KAS, and Starink methods, ranged from 59.61 to 48.63 kJ/mol, 56.05 to 35.12 kJ/mol, and 56.27 to 35.74 kJ/mol, respectively. Correspondingly, sample-2 activation energies ranged from 106.7 to 72.31 kJ/mol, 95.31 to 84.67 kJ/mol, and 106.35 to 72.92 kJ/mol, respectively. Additionally, multiple machine learning models, such as linear regression, polynomial regression, decision tree regression, and random forest regression, are developed to predict the degradation of prepared hydrochar samples. In these machine learning models, experimental TGA mass loss data samples are predicted by utilizing the corresponding heating rate and temperature data of the developed samples. Among all of these, the polynomial regression model is showing higher prediction performance (i.e., RMSE = 0.015282, R2 = 0.9971) than that of the remaining developed ML models.

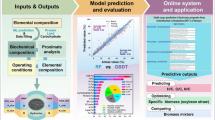

Graphical abstract

Similar content being viewed by others

Data availability

Not applicable.

References

Kumar KR, Balasubramanian KR, Kumar GP, Bharat Kumar C, Cheepu MM (2022) Experimental investigation of nano-encapsulated molten salt for medium-temperature thermal storage systems and modeling of neural networks. Int J Thermophys 43(9):145

Ramaraj BK, Kottala RK (2023) Preparation and characterisation of binary eutectic phase change material/activated porous bio char/multi walled carbon nano tubes as composite phase change material. Fuller Nanotub Carbon Nanostruct 31(1):75–89

Heidari M, Dutta A, Acharya B, Mahmud S (2019) A review of the current knowledge and challenges of hydrothermal carbonization for biomass conversion. J Energy Inst 92(6):1779–1799

Zhang Z, Zhu Z, Shen B, Liu L (2019) Insights into biochar and hydrochar production and applications: a review. Energy 171:581–598

Kambo HS, Dutta A (2015) A comparative review of biochar and hydrochar in terms of production, physico-chemical properties and applications. Renew Sustain Energy Rev 45:359–378

Shafizadeh A, Shahbeik H, Rafiee S, Moradi A, Shahbaz M, Madadi M, Aghbashlo M (2023) Machine learning-based characterization of hydrochar from biomass: implications for sustainable energy and material production. Fuel 347:128467

Cavali M, Junior NL, de Sena JD, Woiciechowski AL, Soccol CR, Belli Filho P, de Castilhos Junior AB (2023) A review on hydrothermal carbonization of potential biomass wastes, characterization and environmental applications of hydrochar, and biorefinery perspectives of the process. Sci Total Environ 857:159627

Fang J, Zhan L, Ok YS, Gao B (2018) Minireview of potential applications of hydrochar derived from hydrothermal carbonization of biomass. J Ind Eng Chem 57:15–21

Liang W, Wang G, Xu R, Ning X, Zhang J, Guo X, Wang C (2022) Hydrothermal carbonization of forest waste into solid fuel: mechanism and combustion behavior. Energy 246:123343

Wilk M, Śliz M, Gajek M (2021) The effects of hydrothermal carbonization operating parameters on high-value hydrochar derived from beet pulp. Renew Energy 177:216–228

Roslan SZ, Zainudin SF, Aris AM, Chin KB, Musa M, Daud ARM, Syed Hassan SSA (2023) Hydrothermal carbonization of sewage sludge into solid biofuel: influences of process conditions on the energetic properties of hydrochar. Energies 16(5):2483

Cavali M, Benbelkacem H, Kim B, Bayard R, Libardi N Jr, Domingos DG, Woiciechowski AL, de Castilhos Jr AB (2023) Co-hydrothermal carbonization of pine residual sawdust and non-dewatered sewage sludge–effect of reaction conditions on hydrochar characteristics. J Environ Manag 340:117994

Wei J, Wang M, Li B, Song X, Yu G, Zhang J, Xu D (2023) Synergy mechanism of biochar and petcoke co-combustion based on potassium migration and transformation. Fuel Process Technol 250:107927

Lang Q, Liu Z, Li Y, Xu J, Li J, Liu B, Sun Q (2022) Combustion characteristics, kinetic and thermodynamic analyses of hydrochars derived from hydrothermal carbonization of cattle manure. J Environ Chem Eng 10(1):106938

Kojić MM, Petrović JT, Petrović MS, Stanković SM, Porobić SJ, Marinović-Cincović MT, Mihajlović ML (2021) Hydrothermal carbonization of spent mushroom substrate: physicochemical characterization, combustion behavior, kinetic and thermodynamic study. J Anal Appl Pyrol 155:105028

Dong X, Guo S, Ma M, Zheng H, Gao X, Wang S, Zhang H (2020) Hydrothermal carbonization of millet stalk and dilute-acid-impregnated millet stalk: combustion behaviors of hydrochars by thermogravimetric analysis and a novel mixed-function fitting method. Fuel 273:117734

Lang Q, Zhang B, Liu Z, Chen Z, Xia Y, Li D, Gai C (2019) Co-hydrothermal carbonization of corn stalk and swine manure: combustion behavior of hydrochar by thermogravimetric analysis. Bioresour Technol 271:75–83

Zhao L, Sun ZF, Pan XW, Tan JY, Yang SS, Wu JT, Ren NQ (2023) Sewage sludge derived biochar for environmental improvement: advances, challenges, and solutions. Water Res 18:100167

Shan G, Li W, Bao S, Li Y, Tan W (2023) Co-hydrothermal carbonization of agricultural waste and sewage sludge for product quality improvement: fuel properties of hydrochar and fertilizer quality of aqueous phase. J Environ Manage 326:116781

Wilk M, Czerwińska K, Śliz M, Imbierowicz M (2023) Hydrothermal carbonization of sewage sludge: hydrochar properties and processing water treatment by distillation and wet oxidation. Energy Rep 9:39–58

Zhang Bo, Wang J, Zhixiang Xu, Shiliang Wu, Luque R, Zhang H (2023) Sewage sludge valorisation by hydrothermal carbonization: a new method to enhance nitrogen removal in hydrochar catalyzed with Ni–Mg–Al layered double oxides. J Clean Prod 386:135880

Zhang HF, Du GQ, Dong QH, Lv CX, Shi SM, Dong CQ (2012) Combustion properties of mixed biomass fuel in thermogravimetric analyzer. Adv Mater Res 347:75–80

Khan SA, Ali I, Naqvi SR, Li K, Mehran MT, Khoja AH, Alarabi AA, Atabani AE (2021) Investigation of slow pyrolysis mechanism and kinetic modeling of Scenedesmus quadricauda biomass. J Anal Appl Pyrolysis 158:105149

Naqvi SR, Ullah Z, Taqvi SAA, Khan MNA, Farooq W, Mehran MT, Juchelková D, Štěpanec L (2023) Applications of machine learning in thermochemical conversion of biomass-a review. Fuel 332:126055

Ullah H, UlHaq Z, Naqvi SR, Khan MNA, Ahsan M, Wang J (2023) Optimization based comparative study of machine learning methods for the prediction of bio-oil produced from microalgae via pyrolysis. J Anal Appl Pyrolysis 170:105879

Kottala RK, Chigilipalli BK, Mukuloth S, Shanmugam R, Kantumuchu VC, Ainapurapu SB, Cheepu M (2023) Thermal degradation studies and machine learning modelling of nano-enhanced sugar alcohol-based phase change materials for medium temperature applications. Energies 16(5):2187

Balasubramanian KR, Ravi Kumar K, Sathiya Prabhakaran SP, Jinshah BS, Abhishek N (2022) Thermal degradation studies and hybrid neural network modelling of eutectic phase change material composites. Int J Energy Res 46(11):15733–15755

Ozawa T (1965) A new method of analyzing thermogravimetric data. Bull Chem Soc Jpn 38(11):1881–1886

Starink MJ (1996) A new method for the derivation of activation energies from experiments performed at constant heating rate. Thermochim Acta 288(1–2):97–104

Jagtap A, Kalbande SR (2022) Investigation on pyrolysis kinetics and thermodynamic parameters of soybean straw: a comparative study using model-free methods. Biomass Convers Bioref 12:1–2

Kottala RK, Balasubramanian KR, Jinshah BS, Divakar S, Chigilipalli BK (2023) Experimental investigation and machine learning modelling of phase change material-based receiver tube for natural circulated solar parabolic trough system under various weather conditions. J Therm Anal Calorim 148:7101–7124

Afolabi OOD, Sohail M, Cheng Y-L (2020) Optimisation and characterisation of hydrochar production from spent coffee grounds by hydrothermal carbonisation. Renew Energy 147:1380–1391

Wu Ke, Gao Y, Zhu G, Zhu J, Yuan Q, Chen Y, Cai M, Feng L (2017) Characterization of dairy manure hydrochar and aqueous phase products generated by hydrothermal carbonization at different temperatures. J Anal Appl Pyrol 127:335–342

Barbanera M, Cotana F, Di Matteo U (2018) Co-combustion performance and kinetic study of solid digestate with gasification biochar. Renew Energy 121:597–605

Vuppaladadiyam AK, Liu H, Zhao M, Soomro AF, Memon MZ, Dupont V (2019) Thermogravimetric and kinetic analysis to discern synergy during the co-pyrolysis of microalgae and swine manure digestate. Biotechnol Biofuels 12:1–18

Naqvi SR, Tariq R, Hameed Z, Ali I, Naqvi M, Chen WH, Ceylan S, Rashid H, Ahmad J, Taqvi SA, Shahbaz M (2019) Pyrolysis of high ash sewage sludge: kinetics and thermodynamic analysis using Coats-Redfern method. Renew Energy 131:854–860

Dubdub I, Al-Yaari M (2020) Pyrolysis of low density polyethylene: kinetic study using TGA data and ANN prediction. Polymers 12(4):891

SathiyaPrabhakaran SP, Swaminathan G, Joshi VV (2021) Thermogravimetric analysis of hazardous waste: pet-coke, by kinetic models and artificial neural network modeling. Fuel 287:119470

Naqvi SR, Tariq R, Hameed Z, Ali I, Taqvi SA, Naqvi M, Niazi MBK, Noor T, Farooq W (2018) Pyrolysis of high-ash sewage sludge: thermo-kinetic study using TGA and artificial neural networks. Fuel 233:529–538

Chun Y, Sheng G, Chiou CT, Xing B (2004) Compositions and sorptive properties of crop residue-derived chars. Environ Sci Technol 38(17):4649–4655

Schimmelpfennig S, Glaser B (2012) One step forward toward characterization: some important material properties to distinguish biochars. J Environ Qual 41(4):1001–1013

Author information

Authors and Affiliations

Contributions

D. Venkata Padma and Kottala Ravi Kumar have done the experimentation. S. V. A. R. Sastry has done the manuscript preparation. Praveen Barmavatu has done the result analysis.

Corresponding author

Ethics declarations

Ethical approval

Not applicable.

Competing interests

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Padma, D.V., Kumar, K.R., Sastry, S.V.A.R. et al. Studies on thermal degradation kinetics and machine learning modeling of hydrochar produced from hydrothermal carbonization of municipal sewage sludge and key lime peel. Biomass Conv. Bioref. (2024). https://doi.org/10.1007/s13399-024-05749-1

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s13399-024-05749-1