Abstract

The dried bark of Eucalyptus grandis (EG) was treated in alkaline (NaOH) and alkaline peroxide (NaOH along with H2O2) solution at 60 °C (AHP-60), 80 °C (AHP-80) and in an autoclave at 121 °C and a pressure of 15 lb/\({{\text{in}}}^{2}\) (AAHP). The structural and chemical changes during pretreatment with alkaline and alkaline peroxide were observed through FTIR, XRD analysis and DNS assay. The effects of NaOH and H2O2 concentration and temperature on lignin removal efficiency and production of reducing sugar were studied. Kinetic parameters of enzymatic hydrolysis and fermentation were evaluated. The results indicated the removal of lignin and easy accessibility of cellulose as the crystallinity of the pretreated Eucalyptus grandis increased. The lignin removal was highest (73.20%) for AAHP. A maximum reducing sugar yield of 215.5 mg/g was also obtained from the same pretreatment conditions confirming the recalcitrance nature of lignin is the key inhibitory factor for the production of reducing sugars. During enzymatic hydrolysis, glucose concentration is observed to be increased over time with the increase in substrate concentration for a particular enzyme loading. EG in AAHP upon enzymatic hydrolysis generates the highest amount of reducing sugar and yields better ethanol conversion (9.941 g/g). The kinetic parameters from hydrolysis and fermentation indicate no inhibition of enzymes by substrate and product.

Similar content being viewed by others

Data availability

All data generated or analyzed during this study are included in this research article.

References

Agbor VB, Cicek N, Sparling R, Berlin A, Levin DB (2011) Biomass pretreatment: fundamentals toward application. Biotechnol Adv 29(6):675–685. https://doi.org/10.1016/J.BIOTECHADV.2011.05.005

Pan X, Xie D, Gilkes N, Gregg DJ, Saddler JN (2005) Strategies to enhance the enzymatic hydrolysis of pretreated softwood with high residual lignin content. In: Twenty-Sixth Symposium on Biotechnology for Fuels and Chemicals, Totowa, NJ: Humana Press, pp 1069–1079. https://doi.org/10.1007/978-1-59259-991-2_90

Himmel ME et al (2007) Biomass recalcitrance: engineering plants and enzymes for biofuels production. Science 1979 315(5813):804–807. https://doi.org/10.1126/science.1137016

Li C et al (2011) Influence of physico-chemical changes on enzymatic digestibility of ionic liquid and AFEX pretreated corn stover. Bioresour Technol 102(13):6928–6936. https://doi.org/10.1016/j.biortech.2011.04.005

Mosier N et al (2005) Features of promising technologies for pretreatment of lignocellulosic biomass. Bioresour Technol 96(6):673–686. https://doi.org/10.1016/j.biortech.2004.06.025

Putro JN, Soetaredjo FE, Lin S-Y, Ju Y-H, Ismadji S (2016) Pretreatment and conversion of lignocellulose biomass into valuable chemicals. RSC Adv 6(52):46834–46852. https://doi.org/10.1039/C6RA09851G

New EK et al (2022) The application of green solvent in a biorefinery using lignocellulosic biomass as a feedstock. J Environ Manage 307:114385

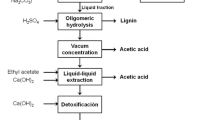

Meléndez-Hernández PA, Hernández-Beltrán JU, Hernández-Guzmán A, Morales-Rodríguez R, Torres-Guzmán JC, Hernández-Escoto H (Oct.2021) Comparative of alkaline hydrogen peroxide pretreatment using NaOH and Ca(OH)2 and their effects on enzymatic hydrolysis and fermentation steps. Biomass Convers Biorefin 11(5):1897–1907. https://doi.org/10.1007/s13399-019-00574-3

Baksi S, Sarkar U, Villa R, Basu D, Sengupta D (2023) Conversion of biomass to biofuels through sugar platform: a review of enzymatic hydrolysis highlighting the trade-off between product and substrate inhibitions. Sustain Energy Technol Assess 55:102963. https://doi.org/10.1016/j.seta.2022.102963

Sun R, Lawther JM, Banks WB (1995) Influence of alkaline pre-treatments on the cell wall components of wheat straw. Ind Crops Prod 4(2):127–145. https://doi.org/10.1016/0926-6690(95)00025-8

Kaar WE, Holtzapple MT (2000) Using lime pretreatment to facilitate the enzymic hydrolysis of corn stover. Biomass Bioenergy 18(3):189–199. https://doi.org/10.1016/S0961-9534(99)00091-4

Ho MC et al (2019) An application of low concentration alkaline hydrogen peroxide at non-severe pretreatment conditions together with deep eutectic solvent to improve delignification of oil palm fronds. Cellulose 26:8557–8573

Taherzadeh M, Karimi K (2008) Pretreatment of Lignocellulosic wastes to improve ethanol and biogas production: a review. Int J Mol Sci 9(9):1621–1651. https://doi.org/10.3390/ijms9091621

Xia Y et al (2022) Structural evolution during corn stalk acidic and alkaline hydrogen peroxide pretreatment. Ind Crops Prod 176:114386. https://doi.org/10.1016/j.indcrop.2021.114386

Huang C et al (2022) The bamboo delignification saturation point in alkaline hydrogen peroxide pretreatment and its association with enzymatic hydrolysis. Bioresour Technol 359. https://doi.org/10.1016/j.biortech.2022.127462

Yong KJ, Wu TY (2023) Recent advances in the application of alcohols in extracting lignin with preserved β-O-4 content from lignocellulosic biomass, BioresourTechnol p 129238

Romaní A et al (2019) Valorization of Eucalyptus nitens bark by organosolv pretreatment for the production of advanced biofuels. Ind Crops Prod 132:327–335. https://doi.org/10.1016/J.INDCROP.2019.02.040

Reina L, Botto E, Mantero C, Moyna P, Menéndez P (2016) Production of second generation ethanol using Eucalyptus dunnii bark residues and ionic liquid pretreatment. Biomass Bioenergy 93:116–121. https://doi.org/10.1016/j.biombioe.2016.06.023

Gomes DG, Michelin M, Romaní A, Domingues L, Teixeira JA (2021) Co-production of biofuels and value-added compounds from industrial Eucalyptus globulus bark residues using hydrothermal treatment. Fuel 285. https://doi.org/10.1016/J.FUEL.2020.119265

Sardar S, Das A, Saha S, Mondal C (2021) Efficient alkaline peroxide pretreatment of sterculia foetida fruit shells for production of reducing sugar: effect of process parameters on lignin removal. In: Proceedings of the 7th International Conference on Advances in Energy Research, M. Bose and A. Modi, Eds., Singapore: Springer Singapore. pp 1441–1451

Segal L, Creely JJ, Martin AE, Conrad CM (1959) An empirical method for estimating the degree of crystallinity of native cellulose using the x-ray diffractometer. Text Res J 29(10):786–794. https://doi.org/10.1177/004051755902901003

D. C. W., In pulp bleaching : principles and practice. Tappi J, vol 42, pp 125–129, 1996. [Online]. Available: https://cir.nii.ac.jp/crid/1571417126191831040.bib?lang=en. Accessed 02 Feb 2023

Miller GL (1959) Use of dinitrosalicylic acid reagent for determination of reducing sugar. Anal Chem 31(3):426–428. https://doi.org/10.1021/ac60147a030

Pazó JA, Granada E, Saavedra Á, Patiño D, Collazo J (2010) Heterogenic solid biofuel sampling methodology and uncertainty associated with prompt analysis. Int J Mol Sci 11(5):2118–2133. https://doi.org/10.3390/ijms11052118

Sluiter A et al (2008) Determination of total solids in biomass and total dissolved solids in liquid process samples. Natl Renew Energy Lab 9:1–6

D. ASTM (1989) 3175–89, standards test method for volatile matter in the analysis sample of coal and coke. Gaseous Fuels, Coal and Coke, p 5

Sluiter A, Hames B, Ruiz R, Scarlata C, Sluiter J, Templeton J (2005) NREL/TP-510-42622: determination of ash in biomass. Natl Renew Energy Lab 36(4):302–305

Basta AH, Fierro V, El-Saied H, Celzard A (2009) 2-Steps KOH activation of rice straw: an efficient method for preparing high-performance activated carbons. Bioresour Technol 100(17):3941–3947. https://doi.org/10.1016/j.biortech.2009.02.028

Chen L, Hong F, Yang X, Han S (2013) Biotransformation of wheat straw to bacterial cellulose and its mechanism. Bioresour Technol 135:464–468. https://doi.org/10.1016/j.biortech.2012.10.029

Andrić P, Meyer AS, Jensen PA, Dam-Johansen K (2010) Effect and modeling of glucose inhibition and in situ glucose removal during enzymatic hydrolysis of pretreated wheat straw. Appl Biochem Biotechnol 160(1):280–297. https://doi.org/10.1007/s12010-008-8512-9

Baksi S et al (2019) Studies on delignification and inhibitory enzyme kinetics of alkaline peroxide pre-treated pine and deodar saw dust. Chem Eng Process - Process Intensif 143:107607. https://doi.org/10.1016/j.cep.2019.107607

Nidetzky B, Steiner W, Hayn M, Claeyssens M (1994) Cellulose hydrolysis by the cellulases from Trichoderma reesei : a new model for synergistic interaction. Biochem J 298(3):705–710. https://doi.org/10.1042/bj2980705

Li C, Yoshimoto M, Tsukuda N, Fukunaga K, Nakao K (2004) A kinetic study on enzymatic hydrolysis of a variety of pulps for its enhancement with continuous ultrasonic irradiation. Biochem Eng J 19(2):155–164. https://doi.org/10.1016/j.bej.2003.12.010

Young J, Lee PJ, Di Gioia AJ (2006) Fast HPLC analysis for fermentation ethanol processes. Application Note. https://www.waters.com/nextgen/in/en/library/application-notes/2007/hplc-analysis-for-fermentation-ethanol-processes.html

Wang D, Xu Y, Hu J, Zhao G (2004) Fermentation kinetics of different sugars by apple wine yeast Saccharomyces cerevisiae. J Inst Brew 110(4):340–346. https://doi.org/10.1002/j.2050-0416.2004.tb00630.x

Karimi K, Taherzadeh MJ (2016) A critical review of analytical methods in pretreatment of lignocelluloses: composition, imaging, and crystallinity. Bioresour Technol 200:1008–1018. https://doi.org/10.1016/J.BIORTECH.2015.11.022

Sun RC, Fang JM, Tomkinson J (2000) Delignification of rye straw using hydrogen peroxide. Ind Crops Prod 12(2):71–83. https://doi.org/10.1016/S0926-6690(00)00039-X

Bianco F, Şenol H, Papirio S (2021) Enhanced lignocellulosic component removal and biomethane potential from chestnut shell by a combined hydrothermal–alkaline pretreatment. Sci Total Environ 762:144178. https://doi.org/10.1016/J.SCITOTENV.2020.144178

Baksi S et al (2019) Valorization of lignocellulosic waste (Crotalaria juncea) using alkaline peroxide pretreatment under different process conditions: an optimization study on separation of lignin, cellulose, and hemicellulose. J Natl Fibers 16(5):662–676. https://doi.org/10.1080/15440478.2018.1431998

Zhang Y-HP, Lynd LR (2004) Toward an aggregated understanding of enzymatic hydrolysis of cellulose: noncomplexed cellulase systems. Biotechnol Bioeng 88(7):797–824. https://doi.org/10.1002/bit.20282

Arantes V, Saddler JN (2010) Access to cellulose limits the efficiency of enzymatic hydrolysis: the role of amorphogenesis. Biotechnol Biofuels 3(1):4. https://doi.org/10.1186/1754-6834-3-4

Kim SW, Hong C-H, Jeon S-W, Shin H-J (2015) High-yield production of biosugars from Gracilaria verrucosa by acid and enzymatic hydrolysis processes. Bioresour Technol 196:634–641. https://doi.org/10.1016/j.biortech.2015.08.016

Fan M, Dai D, Huang B (2012) Fourier transform infrared spectroscopy for natural fibres. In: Fourier Transform - Materials Analysis. InTech.https://doi.org/10.5772/35482

Poletto M, Pistor V, Zeni M, Zattera AJ (2011) Crystalline properties and decomposition kinetics of cellulose fibers in wood pulp obtained by two pulping processes. Polym Degrad Stab 96(4):679–685. https://doi.org/10.1016/J.POLYMDEGRADSTAB.2010.12.007

Terinte N, Schuster KC, Aktiengesellschaft L (2011) Overview on native cellulose and microcrystalline cellulose I structure studied by X-ray diffraction (WAXD): comparison between measurement techniques. [Online]. Available: https://www.researchgate.net/publication/266593566

Filho GR et al (2007) Characterization of methylcellulose produced from sugar cane bagasse cellulose: crystallinity and thermal properties. Polym Degrad Stab 92(2):205–210. https://doi.org/10.1016/j.polymdegradstab.2006.11.008

Liu L, Sun J, Li M, Wang S, Pei H, Zhang J (2009) Enhanced enzymatic hydrolysis and structural features of corn stover by FeCl3 pretreatment. Bioresour Technol 100(23):5853–5858. https://doi.org/10.1016/J.BIORTECH.2009.06.040

Liao Z, Huang Z, Hu H, Zhang Y, Tan Y (2011) Microscopic structure and properties changes of cassava stillage residue pretreated by mechanical activation. Bioresour Technol 102(17):7953–7958. https://doi.org/10.1016/J.BIORTECH.2011.05.067

Kshirsagar SD, Waghmare PR, ChandrakantLoni P, Patil SA, Govindwar SP (2015) Dilute acid pretreatment of rice straw, structural characterization and optimization of enzymatic hydrolysis conditions by response surface methodology. RSC Adv 5(58):46525–46533. https://doi.org/10.1039/C5RA04430H

Ge J et al (2020) Effect of hydrothermal pretreatment on the demineralization and thermal degradation behavior of eucalyptus. Bioresour Technol 307:123246. https://doi.org/10.1016/J.BIORTECH.2020.123246

Biswas AK, Umeki K, Yang W, Blasiak W (2011) Change of pyrolysis characteristics and structure of woody biomass due to steam explosion pretreatment. Fuel Process Technol 92(10):1849–1854. https://doi.org/10.1016/J.FUPROC.2011.04.038

Wang Z, Hou X, Sun J, Li M, Chen Z, Gao Z (2018) Comparison of ultrasound-assisted ionic liquid and alkaline pretreatment of Eucalyptus for enhancing enzymatic saccharification. Bioresour Technol 254:145–150. https://doi.org/10.1016/J.BIORTECH.2018.01.021

Yang BY, Montgomery R (1996) Alkaline degradation of glucose: effect of initial concentration of reactants. Carbohydr Res 280(1):27–45. https://doi.org/10.1016/0008-6215(95)00294-4

Gupta R, Lee YY (2010) Pretreatment of corn stover and hybrid poplar by sodium hydroxide and hydrogen peroxide. Biotechnol Prog 26(4):1180–1186. https://doi.org/10.1002/btpr.405

Palmqvist E, Arbel B, Agerdal H-H (2000) Fermentation of lignocellulosic hydrolysates. I: inhibition and detoxi®cation

Palmqvist E, Arbel B, Agerdal H-H (2000) Fermentation of lignocellulosic hydrolysates. II: inhibitors and mechanisms of inhibition

Lin Y, Tanaka S (2006) Ethanol fermentation from biomass resources: current state and prospects. Appl Microbiol Biotechnol 69(6):627–642. https://doi.org/10.1007/s00253-005-0229-x

Bisson LF (1999) Stuck and sluggish fermentations. Am J Enol Vitic 50(1):107–119. https://doi.org/10.5344/ajev.1999.50.1.107

Guigou M et al (2023) Ethanol production from eucalyptus sawdust following sequential alkaline thermochemical pretreatment with recovery of extractives. Bioenergy Res. https://doi.org/10.1007/s12155-023-10619-1

Gomes DG, Michelin M, Romaní A, Domingues L, Teixeira JA (2021) Co-production of biofuels and value-added compounds from industrial Eucalyptus globulus bark residues using hydrothermal treatment. Fuel 285:119265. https://doi.org/10.1016/j.fuel.2020.119265

Acknowledgements

The authors acknowledge Metallurgical and Material Engineering Department of Jadavpur University for providing FTIR and XRD facilities and IIT Roorkee for BET facilities to characterize obtained outcomes.

Funding

Funding is provided by the Jadavpur University and Ministry of Human Resource Development, Govt of India, for the research under RUSA (R-11/600/19 dated 11.06.2019) scheme to Dr. Chanchal Mondal.

Author information

Authors and Affiliations

Contributions

Sujata Sardar: conceptualization, investigation, data analysis, and writing the original draft. Chanchal Mondal: funding, resources, and supervision. Saswata Chakraborty: validation of model. Sudeshna Saha: conceptualization, resources, review and editing, and supervision.

Corresponding author

Ethics declarations

Ethical approval

Not applicable.

Competing interests

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Additional statement

The authors would like to declare that the manuscript has not been submitted simultaneously for publication elsewhere.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Sardar, S., Mondal, C., Chakraborty, S. et al. Efficacy of alkaline peroxide pretreatment on Eucalyptus grandis as effective lignin removal strategy for production of ethanol using enzymatic hydrolysis. Biomass Conv. Bioref. (2024). https://doi.org/10.1007/s13399-024-05532-2

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s13399-024-05532-2