Abstract

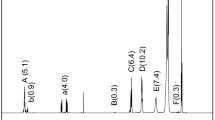

There is a growing interest in utilizing components of oleaginous biomass to create polymeric materials. This study aimed to polymerize the triglyceride of ricinoleic acid, the primary constituent of castor oil, to produce polyricinoleic acid (PRAtriglyc) with varying weight average molar mass (Mw). Acid catalysis was selected due to its ease of use and cost-effectiveness. The first reaction generated a product (PRA1triglyc) with Mw (from size exclusion chromatography) of approximately 6900 g/mol. The PRA1triglyc nuclear magnetic resonance spectra, 1H and 13C confirmed the PRAtriglyc’s formation. Under different conditions of pressure and time, PRAstriglyc 2–4 were synthesized, with Mw of approximately 12,000 g/mol, 17,000 g/mol, and 30,000 g/mol. This latter value is considerably higher than those reported in the literature in which non-enzymatic catalysts were used, as in this study. Thermogravimetric analysis showed that all synthesized polymers have thermal stability up to approximately 350 °C. PRAtriglyc’s are viscous liquids at room temperature and solids at − 20 °C. The solid-state undergoes a glass transition at approximately − 35 °C (from differential scanning calorimetry). Straightforward reactions yielded PRAtriglyc’s with a reasonable Mw range, making them ideal for use as polymeric chain extenders, macromonomers in copolymer synthesis, and other valuable contributions to the circular bioeconomy.

Similar content being viewed by others

Data availability

The manuscript provided the data set generated during the reported study.

References

Teixeira-Costa BE, Andrade CT (2022) Natural polymers used in edible food packaging—history, function and application trends as a sustainable alternative to synthetic plastic. Polysaccharides 3(1):32–58. https://doi.org/10.3390/polysaccharides3010002

Pang C, Zhang J, Wu G, Wang Y, Gao H, Ma J (2014) Renewable polyesters derived from 10-undecenoic acid and vanillic acid with versatile properties. Polym Chem 5(8):2843–2853. https://doi.org/10.1039/C3PY01546G

Prasad RB, Rao BV (2017) Chemical derivatization of castor oil and their industrial utilization. In: Fatty acids. AOCS Press. p 279–303. https://doi.org/10.1016/B978-0-12-809521-8.00008-8

Moshood TD, Nawanir G, Mahmud F, Mohamad F, Ahmad MH, Abdul Ghani A (2021) Expanding policy for biodegradable plastic products and market dynamics of bio-based plastics: challenges and opportunities. Sustain 13(11):6170. https://doi.org/10.3390/su13116170

European Commission (2018) A sustainable bioeconomy for Europe: strengthening the connection between economy, society, and the environment. Update. Bioecon. Strategy. https://ec.europa.eu/research/bioeconomy/index.cfm?pg=policy&lib=strategy. Accessed 15 Sept 2023

Nattrass L, Biggs C, Bauen A, Parisi C, Rodríguez-Cerezo E, & Gómez-Barbero M (2016) The EU bio-based industry: results from a survey. Institute for Prospective and Technological Studies, Joint Research Centre, European Commission

Ahmed MS, Nair KP, Tirth V, Elkhaleefa A, & Rehan M (2021) Tribological evaluation of date seed oil and castor oil blends with halloysite nanotube additives as environment-friendly bio-lubricants. Biomass Convers Biorefin 1–10. https://doi.org/10.1007/s13399-021-02020-9

Pari L, Suardi A, Stefanoni W, Latterini F, Palmieri N (2020) Environmental and economic assessment of castor oil supply chain: a case study. Sustain 12(16):6339. https://doi.org/10.3390/su12166339

Bateni H, Karimi K, Zamani A, Benakashani F (2014) Castor plant for biodiesel, biogas, and ethanol production with a biorefinery processing perspective. Appl Energy 136:14–22. https://doi.org/10.1016/j.apenergy.2014.09.005

Patel A, Gami B, Patel B, Parmar V, & Patel P (2022) Cost benefit and environmental impact assessment of compressed biogas (CBG) production from industrial, agricultural, and community organic waste from India. Biomass Convers Biorefin 1–15. https://doi.org/10.1007/s13399-020-00646-9

Okonkwo CA, Li G, Li Y, Lv T, Jia L, Okoye CC, & Oba SN (2021) Liquid nitrogen-controlled direct pyrolysis/KOH activation mediated micro-mesoporous carbon synthesis from castor shell for enhanced performance of supercapacitor electrode. Biomass Convers Biorefin 1–12. https://doi.org/10.1007/s13399-021-01356-6

Mensah MB, Awudza JAM, O’Brien P (2018) Castor oil: a suitable green source of capping agent for nanoparticle syntheses and facile surface functionalization. R Soc Open Sci 5(8):180824. https://doi.org/10.1098/rsos.180824

Sudheer PD, Chauhan S, Jeon W, Ahn JO, & Choi KY (2021) Monooxygenase-mediated cascade oxidation of fatty acids for the production of biopolymer building blocks. Biomass Convers Biorefin 1–13. https://doi.org/10.1007/s13399-021-01991-z

Rajalakshmi P, Marie JM, Xavier AJM (2019) Castor oil-derived monomer ricinoleic acid based biodegradable unsaturated olyesters. Polym Degrad Stab 170:109016. https://doi.org/10.1016/j.polymdegradstab.2019.109016

Krasko MY, Domb AJ (2005) Hydrolytic degradation of ricinoleic-sebacic-ester-anhydride copolymers. Biomacromol 6(4):1877–1884. https://doi.org/10.1021/bm049228v

Shikanov A, Ezra A, Domb AJ (2005) Poly (sebacic acid-co-ricinoleic acid) biodegradable carrier for paclitaxel—effect of additives. J Controlled Release 105(1–2):52–67. https://doi.org/10.1016/j.jconrel.2005.02.018

Vaisman B, Shikanov A, Domb AJ (2008) The isolation of ricinoleic acid from castor oil by salt-solubility-based fractionation for the biopharmaceutical applications. J Am Oil Chem Soc 85(2):169–184. https://doi.org/10.1007/s11746-007-1172-z

Gioia C, Banella MB, Totaro G, Vannini M, Marchese P, Colonna M, Sisti L, Celli A (2018) Biobased vanillic acid and ricinoleic acid: building blocks for fully renewable copolyesters. J Renewable Mater 6(1):126. https://doi.org/10.7569/JRM.2017.634191

Maia DL, Fernandes FA (2019) Effect of process conditions on the properties of castor oil maleate and styrene copolymer produced by bulk polymerization. Biomass Convers Biorefin 9:411–420. https://doi.org/10.1007/s13399-018-0359-x

Thomas D, Philip E, Sindhu R, Ulaeto SB, Pugazhendhi A, Awasthi MK (2022) Developments in smart organic coatings for anticorrosion applications: a review. Biomass Convers Biorefin 12(10):4683–4699. https://doi.org/10.1007/s13399-022-02363-x

Rawat SS, & Harsha AP (2022) The lubrication effect of different vegetable oil-based greases on steel-steel tribo-pair. Biomass Convers Biorefin 1–13 https://doi.org/10.1007/s13399-022-02471-8

Castro DO, Passador F, Ruvolo-Filho A, Frollini E (2017) Use of castor and canola oils in “biopolyethylene” curauá fiber composites. Compos A Appl Sci Manuf 95:22–30. https://doi.org/10.1016/j.compositesa.2016.12.024

Porto DS, Cassales A, Ciol H, Inada NM, Frollini E (2022) Cellulose as a polyol in the synthesis of bio-based polyurethanes with simultaneous film formation. Cellulose 29(11):6301–6322. https://doi.org/10.1007/s10570-022-04662-y

Cassales A, Ramos LA, Frollini E (2020) Synthesis of bio-based polyurethanes from Kraft lignin and castor oil with simultaneous film formation. Int J Biol Macromol 145:28–41. https://doi.org/10.1016/j.ijbiomac.2019.12.173

de Oliveira F, Goncalves LP, Belgacem MN, Frollini E (2020) Polyurethanes from plant-and fossil-sourced polyols: properties of neat polymers and their sisal composites. Ind Crops Prod 155:112821. https://doi.org/10.1016/j.indcrop.2020.112821

Totaro G, Cruciani L, Vannini M, Mazzola G, Di Gioia D, Celli A, Sisti L (2014) Synthesis of castor oil-derived polyesters with antimicrobial activity. Eur Polym J 56:174–184. https://doi.org/10.1016/j.eurpolymj.2014.04.018

Tonta MM, Aydemir Sezer U, Olmez H, Gurek AG, Sezer S (2019) Cost-effective synthesis of polyricinoleate: investigation of coating characteristics, in vitro degradation, and antibacterial activity. J Appl Polym Sci 136(44):48172. https://doi.org/10.1002/app.48172

Yamamoto et al (2020) Improving thermal and mechanical properties of biomass-based polymers using structurally ordered polyesters from ricinoleic acid and 4-hydroxycinnamic acids. RSC Adv 10(60):36562–36570. https://doi.org/10.1039/D0RA05671E

Totaro G, Sisti L, Cionci NB, Martinez GA, Di Gioia D, Celli A (2020) Elastomeric/antibacterial properties in novel random Ricinus communis based-copolyesters. Polym Test 90:106719. https://doi.org/10.1016/j.polymertesting.2020.106719

Zhang BX, Uyama H (2016) Biomimic plant cuticle from hyperbranched poly (ricinoleic acid) and cellulose film. ACS Sustainable Chem Eng 4(1):363–369. https://doi.org/10.1021/acssuschemeng.5b01392

Kyobe JW, Mubofu EB, Makame YM, Mlowe S, Revaprasadu N (2015) CdSe quantum dots capped with naturally occurring biobased oils. New J Chem 39(9):7251–7259. https://doi.org/10.1039/C5NJ01460C

Trân NB, Vialle J, Pham QT (1997) Castor oil-based polyurethanes: 1. Structural characterization of castor oil—nature of intact glycerides and distribution of hydroxyl groups. Polymer 38(10):2467-2473 https://doi.org/10.1016/S0032-3861(96)00791-4

Ogawa R, Hillmyer MA (2021) High molar mass poly (ricinoleic acid) via entropy-driven ring-opening metathesis polymerization. Polym Chem 12(15):2253–2257. https://doi.org/10.1039/D1PY00185J

Farias M (2010) Synthesis, characterization of catalysts and study of their catalytic activities in the epoxidation of vegetable oils. Doctoral thesis. Federal University of Rio Grande do Sul, Porto Alegre, Brazil

Pavia DL, Lampman GM, Kriz GS, & Vyvyan JR (2009) Introduction to spectroscopy, 4th edn. Brooks, Cole, USA, p 691–695

Ebata H, Yasuda M, Toshima K, Matsumura S (2008) Poly (ricinoleic acid) based novel thermosetting elastomer. J Oleo Sci 57(6):315–320. https://doi.org/10.5650/jos.57.315

Moraes DCD (2015) Synthesis of polymers derived from oleic acid and derived from soybean and canola biodiesel for coatings of Fe3O4 and CoFe2O4 nanoparticles. Doctoral thesis. Federal University of Rio Grande do Sul, Porto Alegre, Brazil

Somani KP, Kansara SS, Patel NK, Rakshit AK (2003) Castor oil based polyurethane adhesives for wood-to-wood bonding. Int J Adhes Adhes 23(4):269–275. https://doi.org/10.1016/S0143-7496(03)00044-7

Vadgama RN, Odaneth AA, & Lali AM (2019) New synthetic route for polyricinoleic acid with Tin (II) 2-ethylhexanoate. Heliyon 5(6). https://doi.org/10.1016/j.heliyon.2019.e01944

Slivniak R, Domb AJ (2005) Lactic acid and ricinoleic acid based copolyesters. Macromolecules 38(13):5545–5553. https://doi.org/10.1021/ma0503918

Funding

CNPq (National Counsel of Technological and Scientific Development, Brazil): research productivity fellowship to E.F. and financial support (Process n° 403494/2021–4); CAPES (Higher Education Personnel Improvement Coordination): fellowship to R. L. P. (Finance Code 001).

Author information

Authors and Affiliations

Contributions

Roberta L. de Paula: conceptualization; methodology; formal analysis; investigation; data curation; writing, original draft; writing, review and editing; and visualization.

Elisabete Frollini: conceptualization; methodology; formal analysis; investigation; resources; writing, original draft; writing, review and editing; visualization; project administration; and funding acquisition.

Corresponding author

Ethics declarations

Ethical approval

Not applicable.

Competing interests

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

de Paula, R.L., Frollini, E. Progress in the synthesis of polyricinoleic acid via acid catalysis from the primary component of castor oil. Biomass Conv. Bioref. (2024). https://doi.org/10.1007/s13399-024-05505-5

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s13399-024-05505-5